In-mold rubber mouth shearing mechanism

A glue mouth and mold technology, which is applied in the field of in-mold glue mouth cutting mechanism, can solve the problems of wasting manpower and equipment, and the cutting place is not beautiful enough, so as to achieve the effect of beautiful cutting place, saving manpower and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

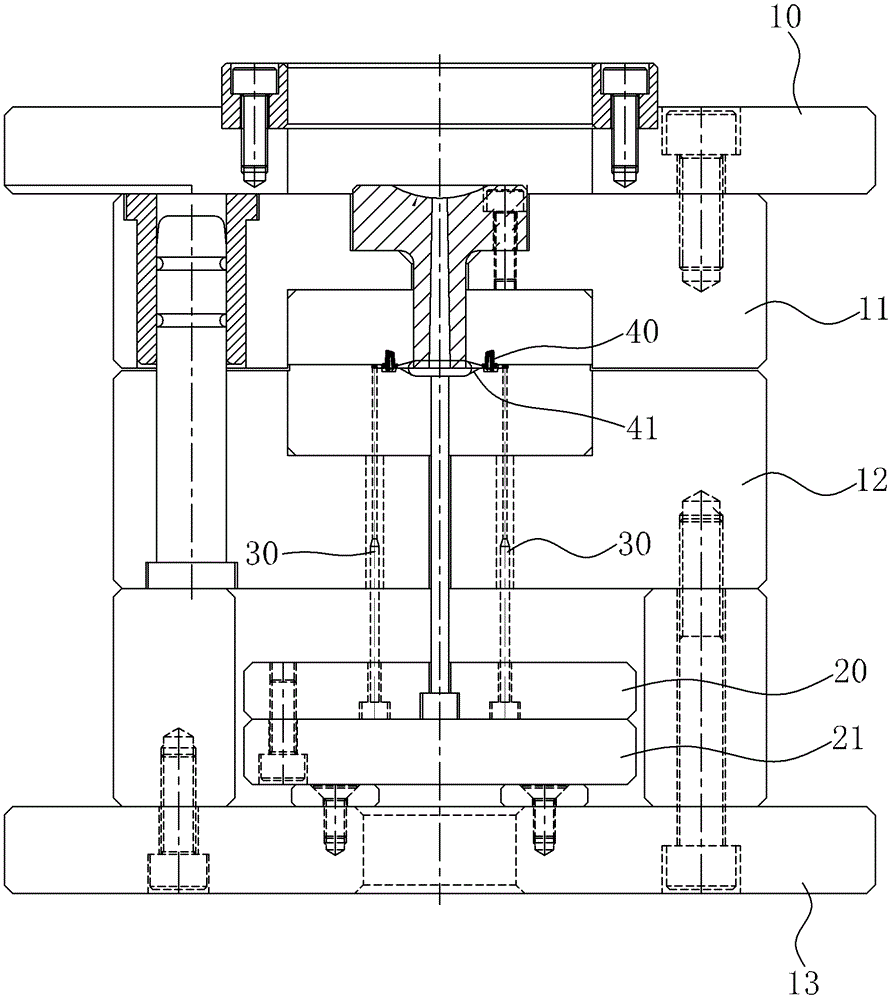

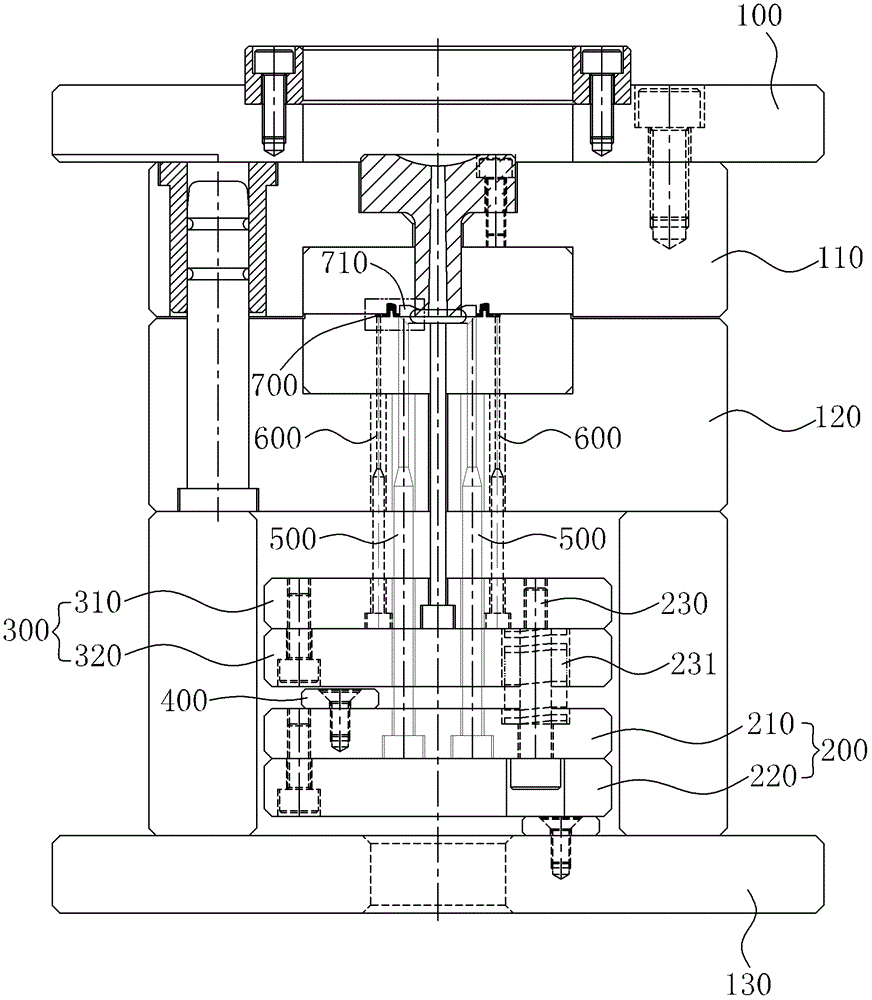

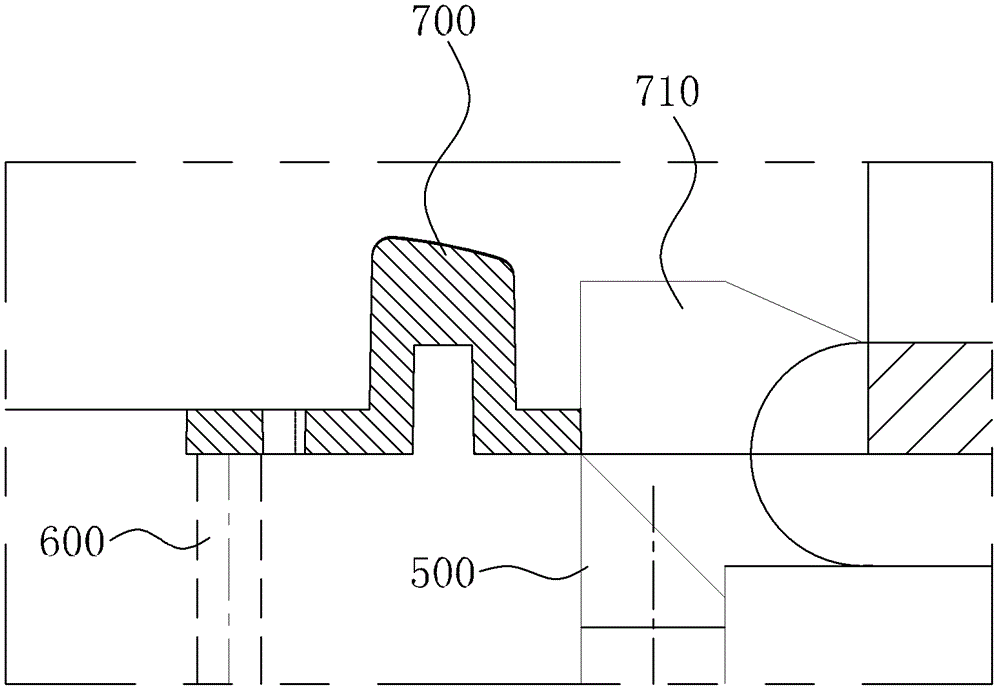

[0022] see figure 2 , image 3 and Figure 4 As shown, the in-mold rubber mouth shearing mechanism of the present invention is applied in a mould. The rubber mouth cutting mechanism includes:

[0023] The first ejector plate 200, which is located above the lower fixing plate 130, the first ejector plate 200 includes a first upper ejector plate 210 and a first lower ejector plate 220;

[0024] The second ejector plate 300 is located above the first ejector plate 200 above. The second ejector plate 300 includes a second upper ejector plate 310 and a second lower ejector plate 320. The lower fixed plate 130 is provided with There is a support column 131 to support the second ejector plate 300, the first ejector plate 200 and the second ejector plate 300 are connected by a contour screw 230, and a first elastic element 231 is arranged outside the contour screw 230, In this embodiment, the first elastic element 231 is a spring;

[0025] Limiting block 400, which is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com