Dimming film cutting method and prepared dimming film thereof

A light-adjustable film and cutting technology, applied in the field of light-adjustable film, can solve problems such as abnormal bright spots and edge short circuits, and achieve the effects of increasing distance, avoiding adhesion, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The dimming film cutting method of the present embodiment comprises the following steps:

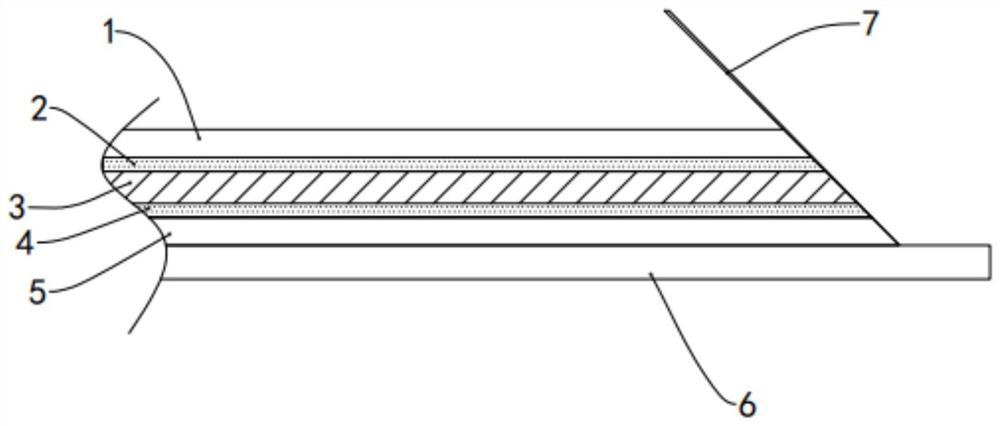

[0022] Step 1: Take a roll of dimming film with the same batch number. like figure 1 As shown, the dimming film includes a first substrate layer 1 , a first conductive layer 2 , a PDLC layer 3 , a second conductive layer 4 and a second substrate layer 5 stacked in sequence. The dimming film is unfolded and squared on the cutting table 6 .

[0023] Step 2: Adjust the existing cutting hob 7 to be inclined at an angle of 45° to the vertical surface perpendicular to the cutting table 6, and then cut according to the required size and surface size to obtain the dimming film 1. Dimming film 2, Dimming film 3, Dimming film 4 and Dimming film 5.

[0024] Step 3: Wipe the cut edges with alcohol to ensure that no impurities remain.

[0025] Step 4: Make electrodes on the dimming film.

[0026] Test the dimming film: test with 48V electricity, dimming film 1, dimming film 2, dimming fil...

Embodiment 2

[0028] The dimming film cutting method of the present embodiment comprises the following steps:

[0029] Step 1: Take a roll of dimming film with the same batch number.

[0030] Step 2: Adjust the inclination angle of the cutting table so that the angle between the plane where the cutting hob is located and the normal line of the cutting table is 30°, and spread the dimming film squarely on the cutting table. Then cut according to the surface size below the required size to obtain the six dimming films, seven dimming films, eight dimming films, nine dimming films and ten dimming films.

[0031] Step 3: Wipe the cut edges with alcohol to ensure that no impurities remain.

[0032] Step 4: Make electrodes on the dimming film.

[0033] Test the dimming film: test with 48V electricity, dimming film 6, dimming film 7, dimming film 8, dimming film 9 and dimming film 10 can light up normally. Test with 60V electricity, dimming film 6, dimming film 7, dimming film 8, dimming film 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com