The central automatic switch reversing device in the slide sorter

A technology of reversing device and sorting machine, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems that the equipment cannot meet the set function, affect the noise index of the equipment, reduce the service life of parts, etc., so as to reduce the actual use cost. And the effect of maintenance cost, service life and reliability improvement, and reduction of installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

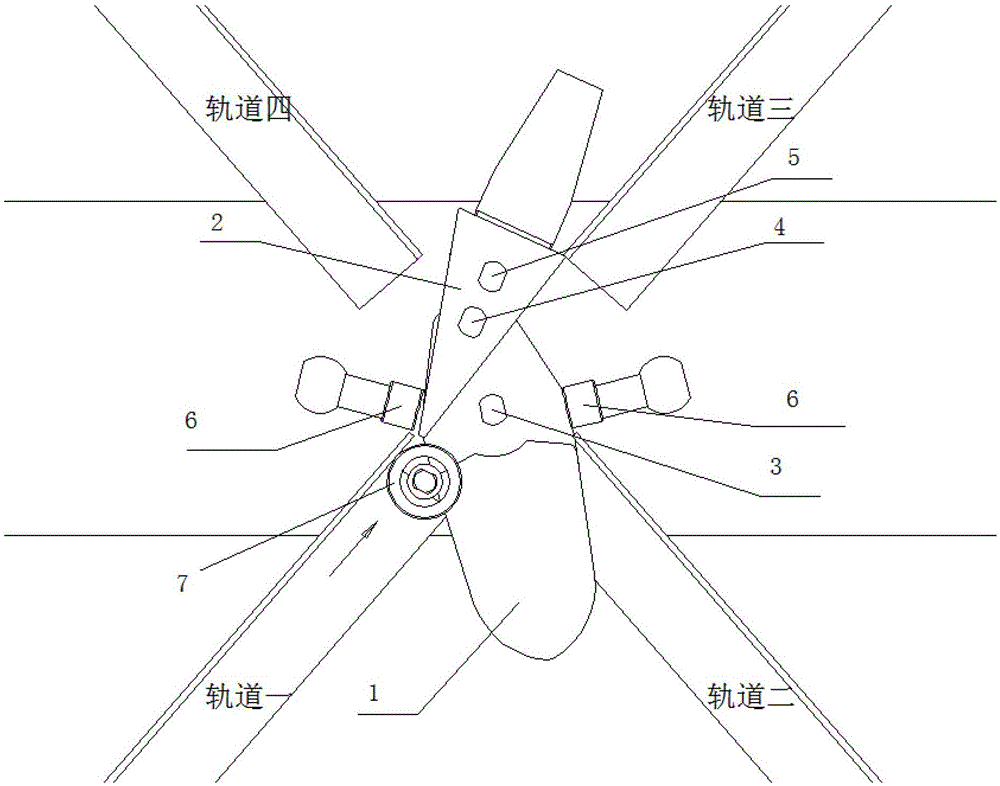

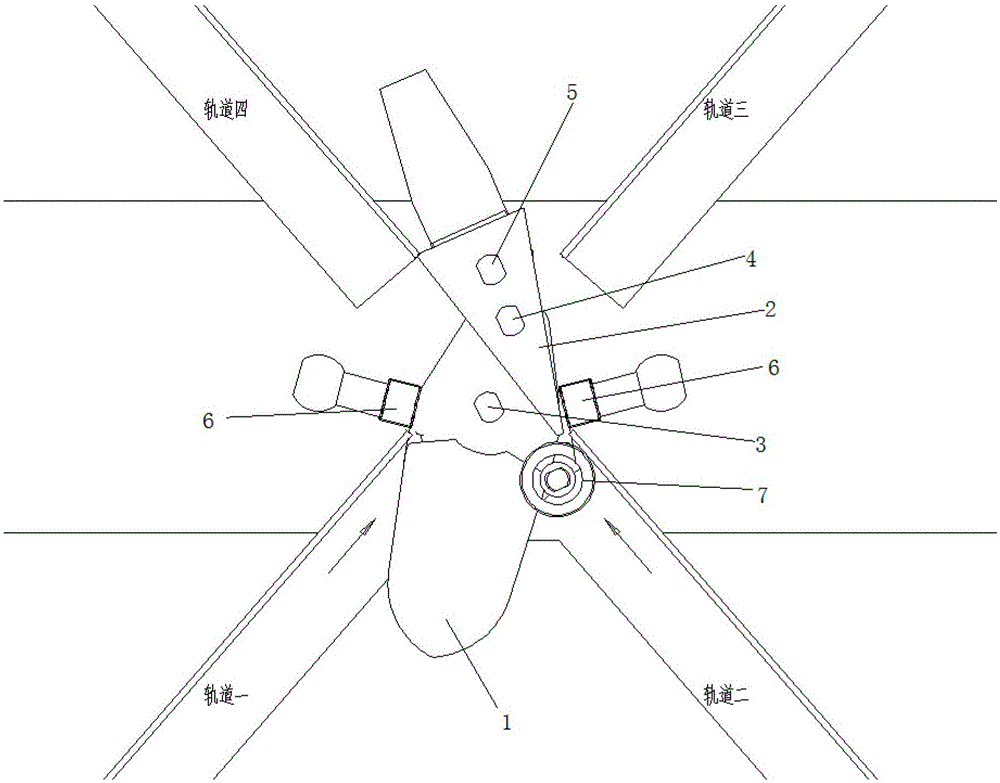

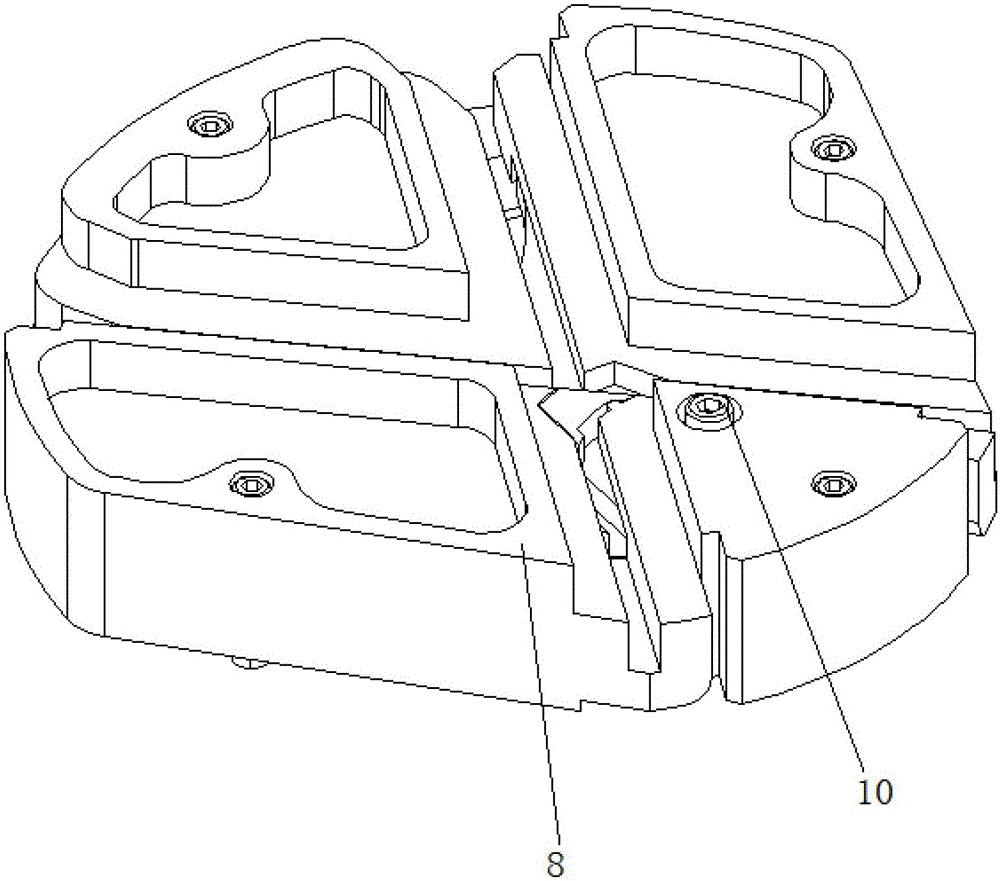

[0032] Such as Figure 3-6 As shown, the central automatic switch reversing device in the slider type sorter of the present invention consists of three main parts in total, including: a fixed plate 8, a guide reversing plate 9 and a rotating shaft 10, wherein there are four on the fixed plate Tracks are track 1, track 2, track 3, and track 4. Track 1 and track 3 are on the same straight line, track 2 and track 4 are on the same straight line, and the straight lines where track 1 and track 3 are located are the same as track 2 and track 3. The four lines intersect. The guide reversing plate 9 is located in the fan-shaped groove below the fixed plate 8, and is hinged with the fixed plate 8 through the rotating shaft 10. There are two tracks on the guide reversing plate 9, namely, the left track and the right track. 9 rotates around the rotating shaft 10, so that the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com