Multi-directional hydraulic systems and apparatus

A technology for hydraulic equipment and liquids, which is used in lifting devices, transportation and packaging, thin material handling, etc. It can solve problems such as inability to reliably transport hydraulic oil without air, failures, and reduced system hydraulic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] hereby attached picture Embodiment The structural features of the present invention and other effects, purpose are described in detail as follows:

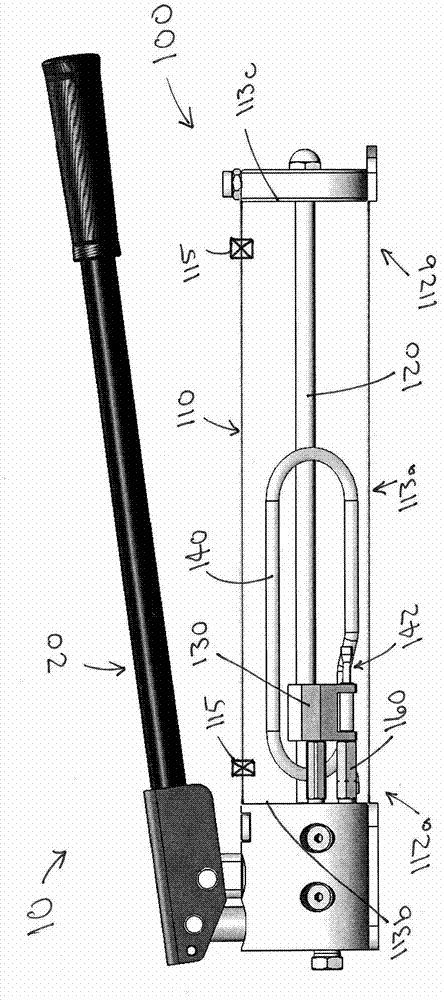

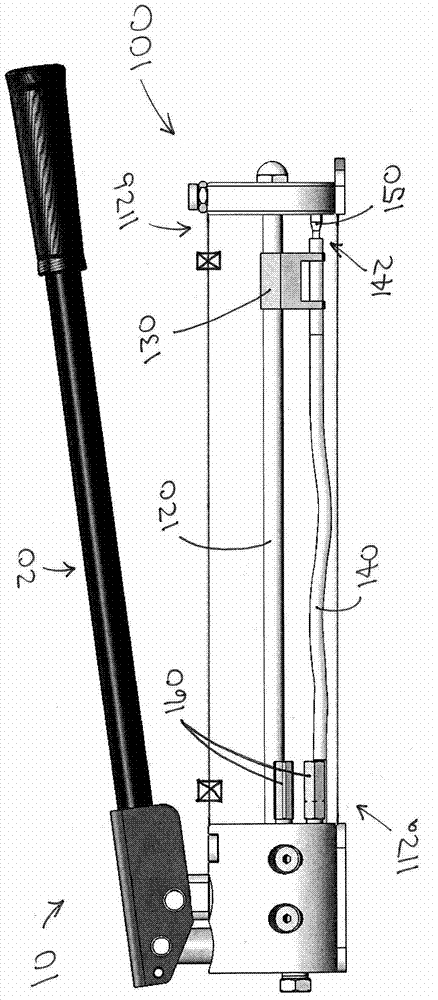

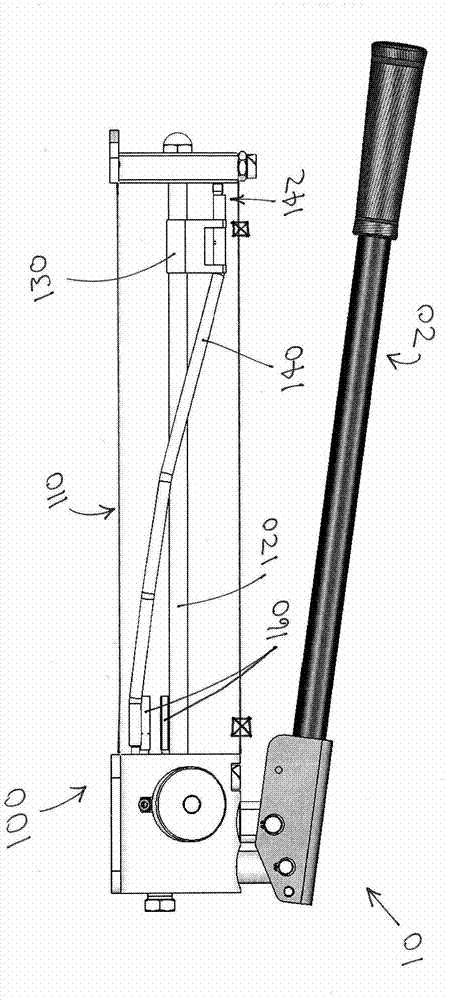

[0015] According to a preferred embodiment of the present invention, the first Figure to fifth picture A portion of a hydraulic device 10 such as a jack is shown. This hydraulic device 10 has a liquid collection system 100, a piston chamber ( picture not shown), a piston that can retract and retract in the piston chamber ( picture not shown) and pump 20.

[0016] The liquid collection system 100 includes: an elongated housing 110 for containing liquid (hydraulic oil), a guide rod 120 , a guide block 130 and a header 140 . as first Figure to third picture As shown, the elongated housing 110 has a proximal end 112a and a distal end 112b; a vent hole 115 is located at both ends of the elongated housing 112a, 112b for exhausting the gas in the elongated housing 110. Elongate housing 110 may be made of any suitable mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com