An intelligent compensation chain packing system

A technology of chain packing and compensating chain, which is applied in the directions of packaging, packing protection, transportation and packaging, etc., can solve the problems of large fluctuation of elastic sliding amount, surface damage of compensation chain, interruption of reel chain packing, etc., and achieves reasonable structural design. The effect of compactness, reduced relative friction, and controllable process chain speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

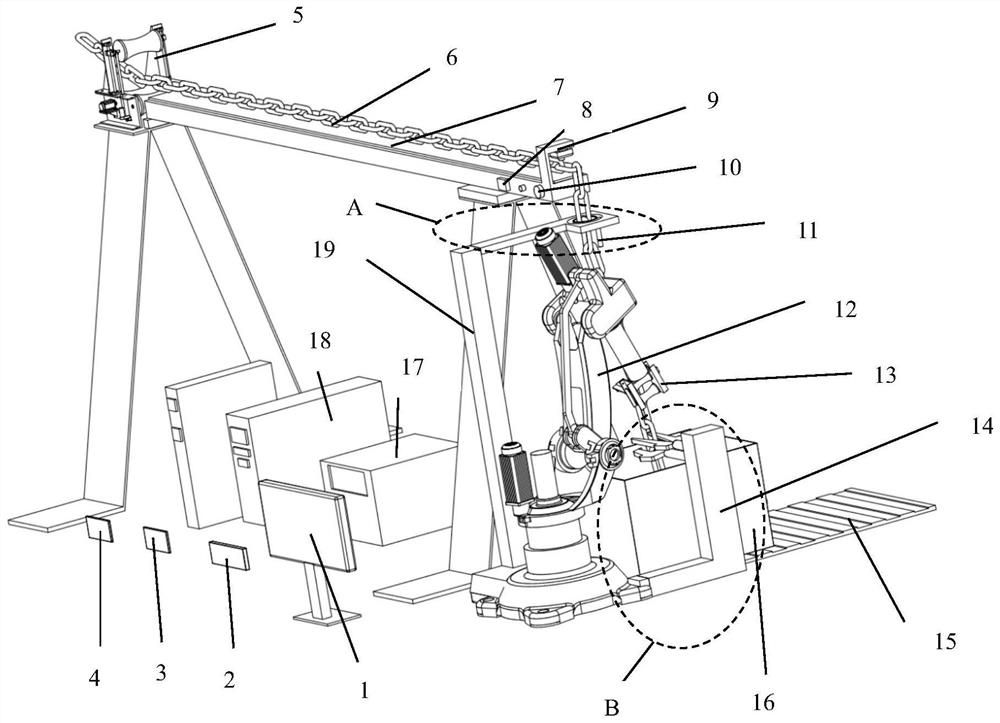

[0027] The invention provides an intelligent compensation chain packing system, which is suitable for the extrusion process of the wrapped elevator compensation chain. Packing can also be used for other needs to automatically coil and pack chains or ropes of different diameters in a racetrack-shaped track or a circular track and precisely control the cutting length.

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

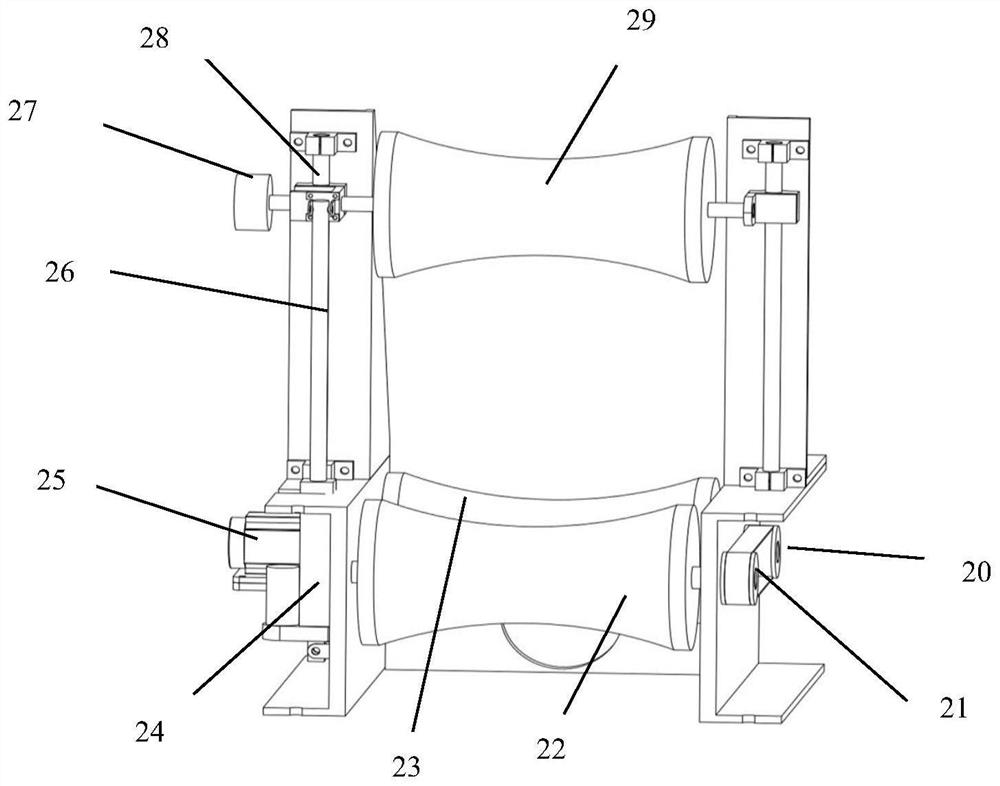

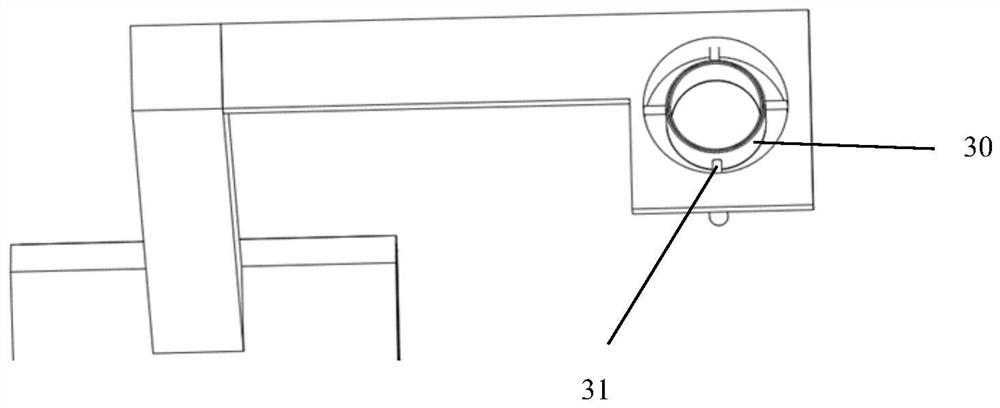

[0029] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention. like figure 1 As shown, the intelligent compensation chain packing system according to the embodiment of the present invention includes a visual recognition module, a six-degree-of-freedom mechanical arm 12, a chain feeding device 5, a chain outputting device 13, a chain supporting device 19, a first conveyor belt 7, a clamping and shearing device The device 14 , the second conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com