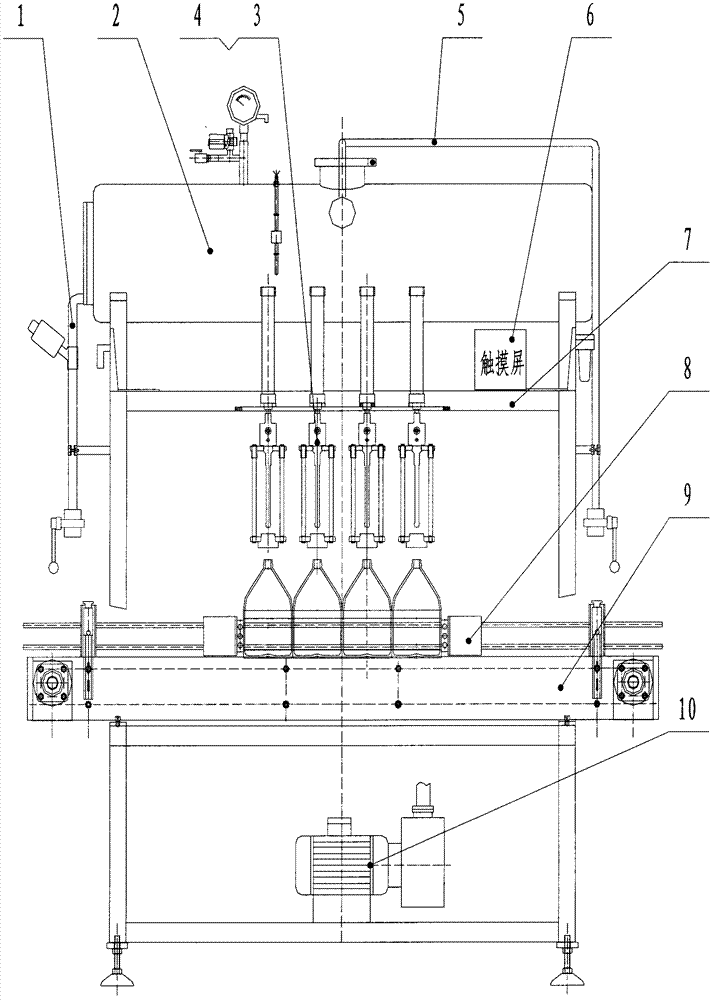

Automatic linear liquid filling machine

A filling machine, straight line technology, used in packaging, bottle filling, liquid bottling, etc., to achieve the effect of stable wine source, consistent liquid level, and reduced wine loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below with reference to the accompanying drawings.

[0011] The whole process is: before filling, connect the power supply, air source and wine source of the equipment, start it through the touch screen, and the conveying chain will be transported by the filled container to the filling head. After reaching the position through infrared detection, the conveyor belt will stop and the bottle will stop. The cylinder is opened, the filling cylinder is opened, the filling head is pressed down to carry out vacuuming, pressure preparation, filling, stabilization, and pressure relief procedures for the container, the filling head is automatically lifted when the wine is full, and the bottle stop cylinder is opened to fill a group of The last container is transported out of the machine, and at the same time, the next group of filled containers is transported to the filling head, completing the entire working process of the automatic lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com