Buckled rapid joint

A crimping and fast technology, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of narrowing the scope of application, more sealing, and lower overall efficiency, and achieve a simple and compact structure. , good sealing, easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

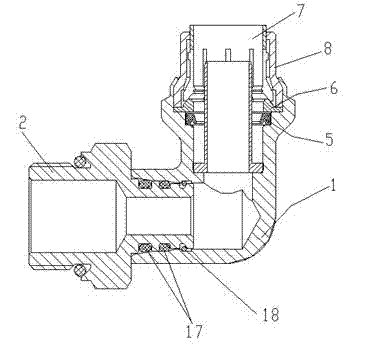

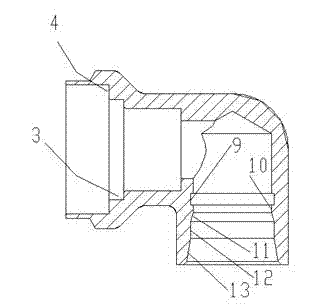

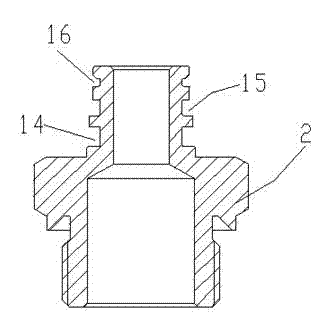

[0042] Reference attached figure 1 To attach Figure 7 As shown, this embodiment discloses a buckle-type quick connector, including a connector 1, characterized in that: a stopper structure is formed at one end of the connector 1, a buckle structure is provided on the stopper structure, and a buckle structure is formed on the inner wall of the other end. A clamping groove structure, the clamping groove structure is provided with a matching quick-connect nut structure.

[0043] It is further provided that the stopper structure includes a first stopper 3 formed on the inner wall of the joint, and a second stopper 4 formed above the first stopper 3 .

[0044] It is further provided that the buckle structure includes a lip seal 5 arranged on the first block 3, a pressure ring 6 is provided on the lip seal 5, and a ferrule 7 is provided ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com