Tea steaming device

A technology for steaming tea and steaming tea buckets is applied in the field of tea steaming devices, which can solve the problems of low production efficiency and inaccurate control of tea steaming time, and achieve the effects of improving production efficiency, accurate steaming time and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

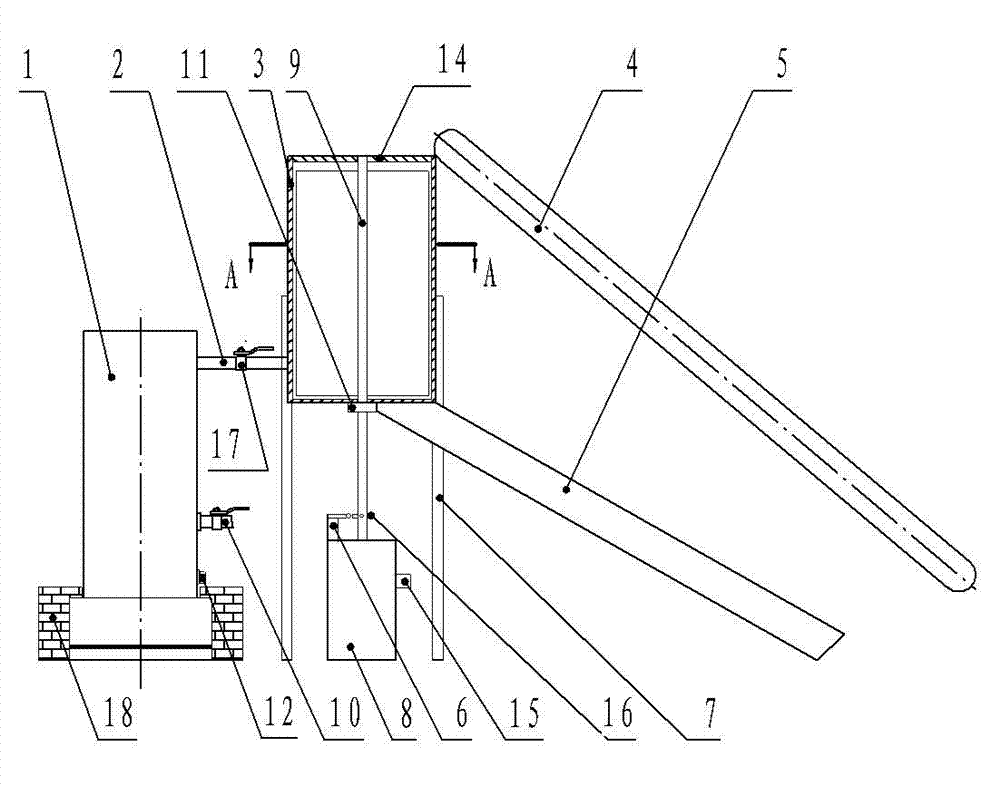

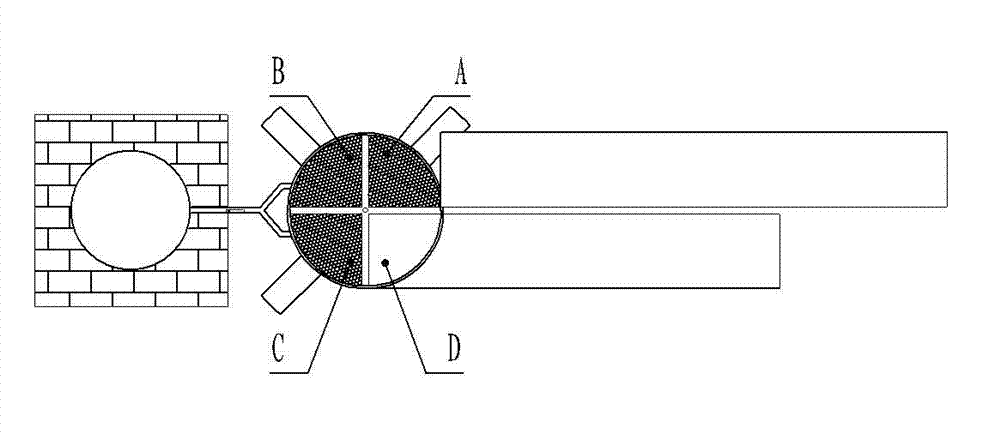

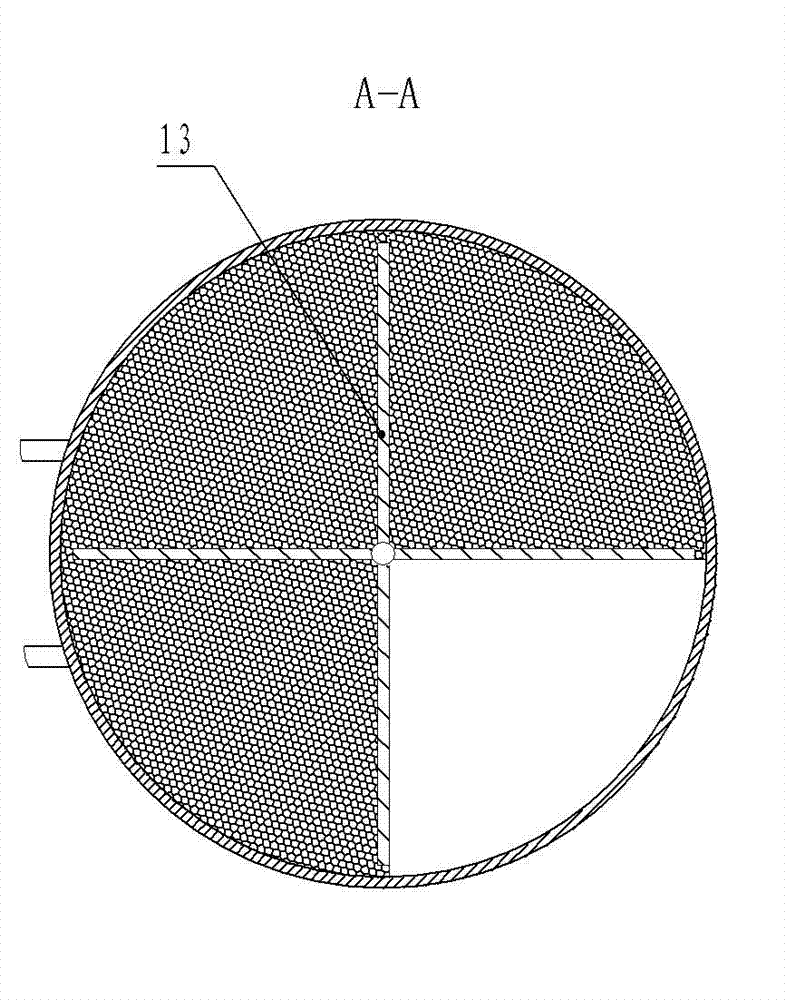

[0019] Below in conjunction with accompanying drawing example the present invention is described in further detail:

[0020] figure 1 , figure 2 , image 3 The shown tea steaming device includes a steam boiler 1 and a tea steaming bucket 3. The tea steaming bucket 3 is installed on a support 7 fixed on the ground. The tea steaming bucket 3 is a cylinder with an open upper end. There are multiple blocks on the bottom plate of the tea steaming bucket 3 , one of the blocks is the gap between the bottom of the steaming tea barrel 3 and the outside, and the remaining blocks are densely covered with a plurality of pores. A rotating shaft 9 is vertically arranged in the tea steaming barrel 3, and a plurality of shafts are vertically fixed on the rotating shaft 9. Partition 13, the number of partitions 13 is the same as the number of blocks, and partition 13 divides the inner cavity of tea steaming bucket 3 into multiple chambers; Bearings are installed, and the bearing 11 protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com