Submersible aeration blender

A mixer and aeration technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of easy dead angle, low intake pressure, small impeller, etc., to ensure service life, enhance thrust, and air flow. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

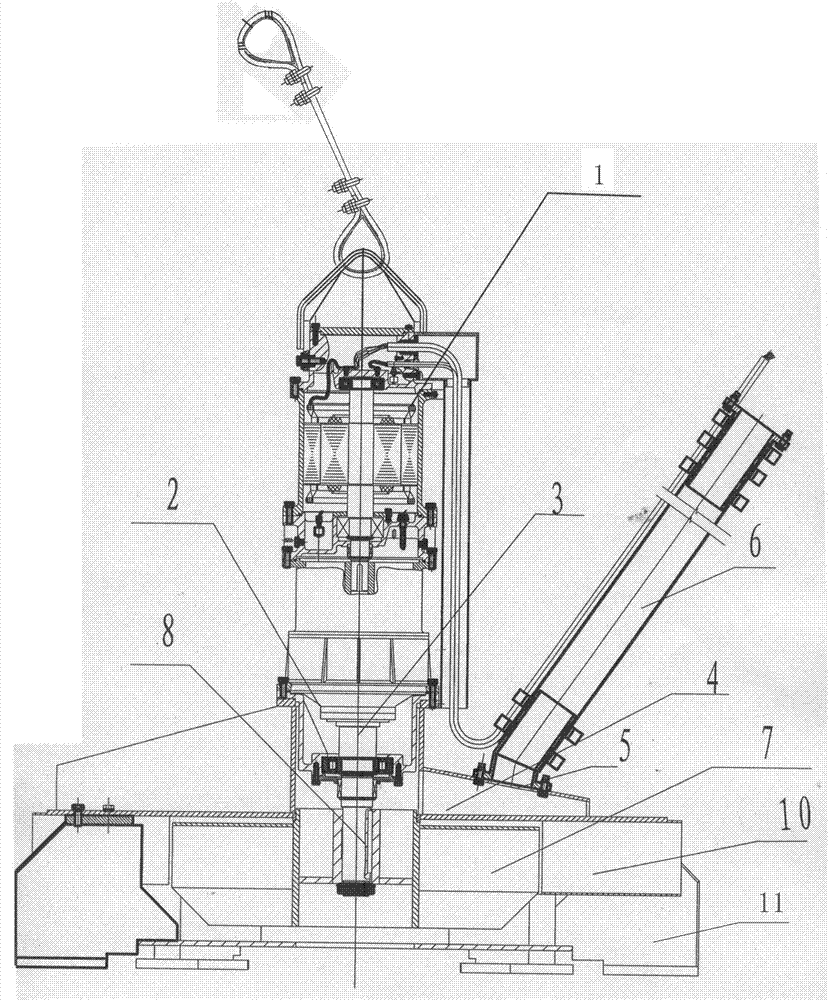

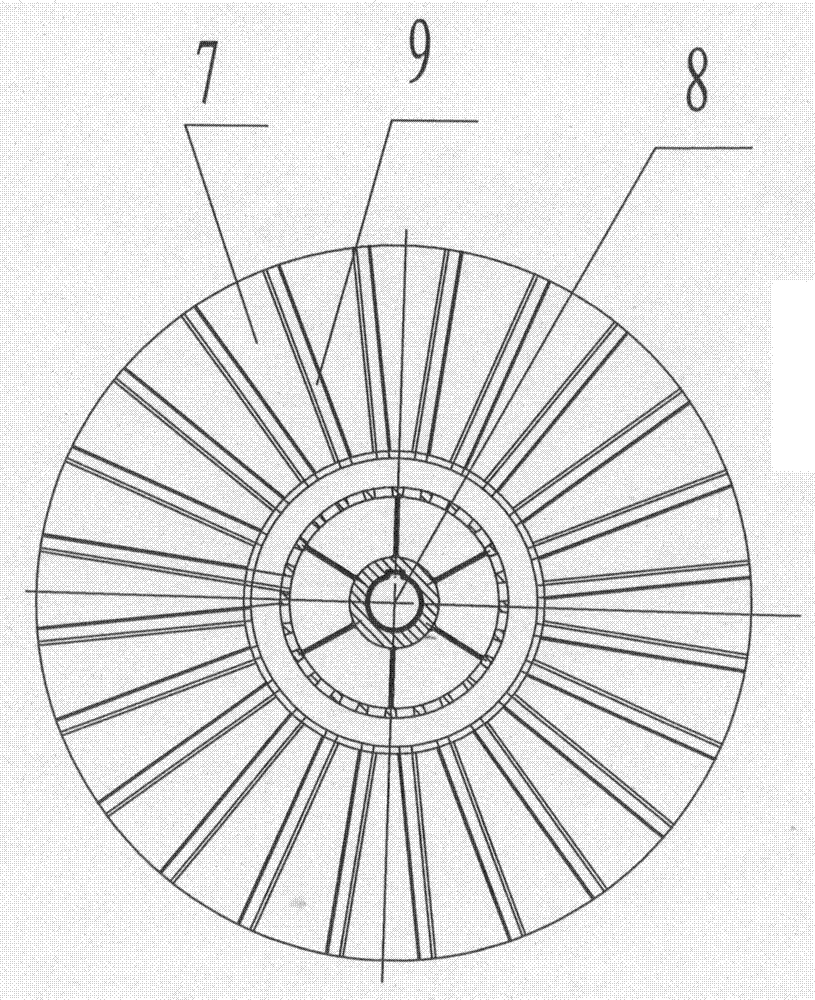

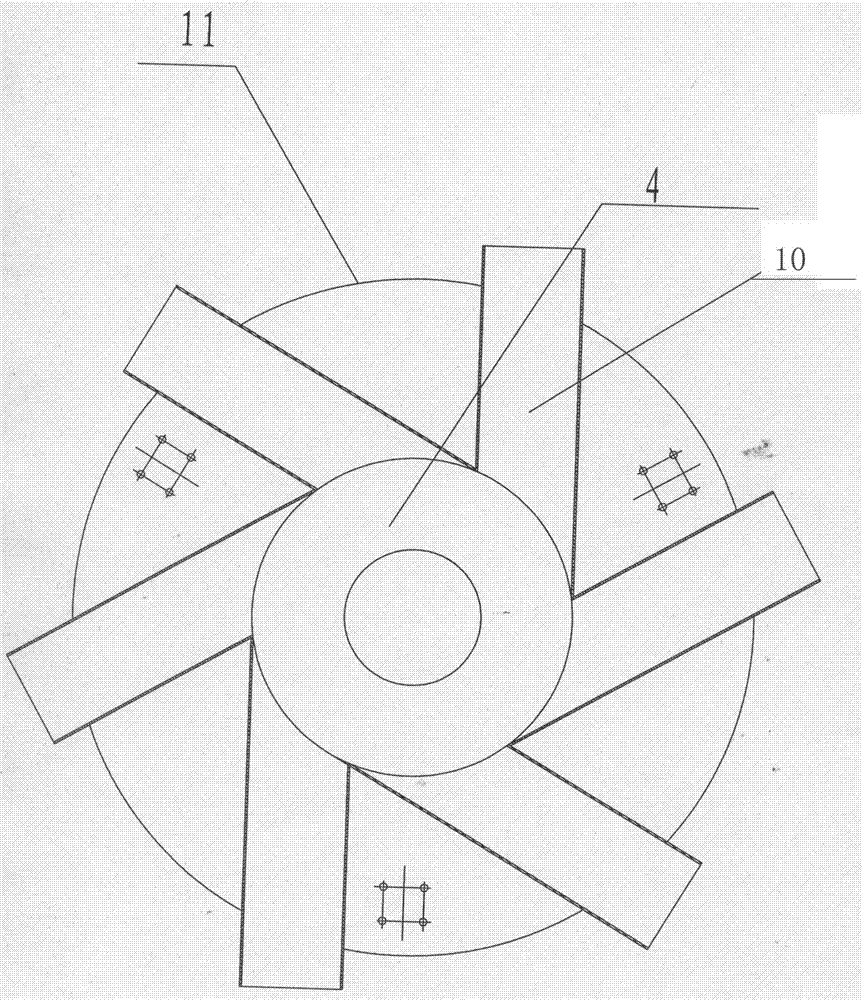

[0010] In Fig. 1, Fig. 2 and Fig. 3, the present invention is a submersible aeration mixer, which includes the main body of the mixer. The main body of the mixer includes a motor 1, a reducer 2, a connecting shaft 3 and an impeller in order from top to bottom, and the motor 1 in turn The reducer 2 and the connecting shaft 3 are connected to the impeller by transmission. The lower part of the mixer body is provided with a mixing chamber 4. The impeller is located in the mixing chamber 4. There are several diffusion pipes 10 distributed around the mixing chamber 4. The diffusion pipes 10 are in a spiral shape. Evenly distributed in the tangential direction of the circumference of the mixing chamber 4 , the bottom of the mixing chamber 4 is provided with a base 11 , an air inlet channel 5 is provided in the mixing chamber 4 , and a compressed air pipe 6 and a compressed air pipe 5 are provided on the surface of the mixing chamber 4 It is obliquely arranged on the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com