Method for controlling upward flotation and deformation of liquefiable ground operating tunnel under action of earthquake

A technology of liquefaction site and control method, applied in tunnels, earth-moving mining, mining equipment, etc., can solve problems such as distortion and deformation, and achieve the effects of small environmental impact, strong operability, and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

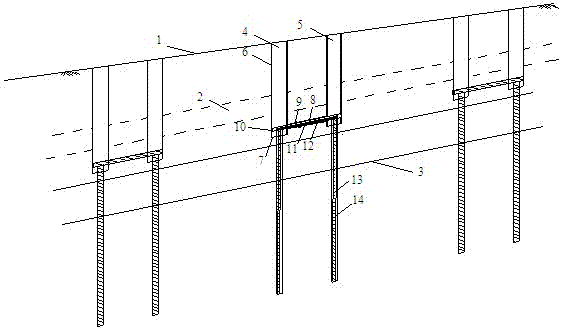

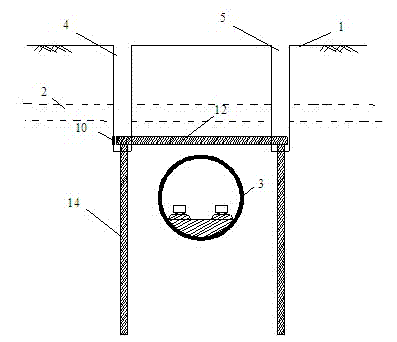

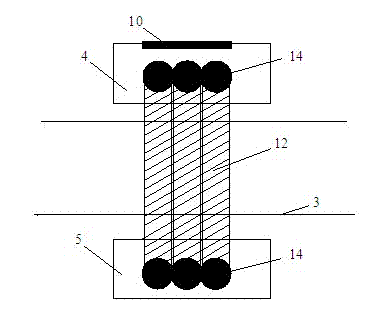

[0028] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The protection scope of the present invention is not limited to the description of this embodiment.

[0029] In the site area below the ground surface 1 containing the liquefiable soil layer 2 and the operating tunnel 3, a method for controlling the floating deformation of the operating tunnel of the liquefaction site under the action of an earthquake, such as Figure 1-3 As shown, it includes starting working well 4, receiving working well 5, underground continuous wall 6, water stop bottom plate 7, culvert pipe 8, culvert pipe grouting pipe 9, top pipe reaction wall 10, top beam reinforcement cage 11, top beam 12 , The cast-in-place pile reinforcement cage 13, and the drilled occluding reinforced concrete cast-in-place pile 14. During the implementation, first measure the line to determine the ground position corresponding to the area of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com