A method for monitoring the section shape of steel truss girders during construction of long-span cable-stayed bridges

A cross-sectional shape and steel truss beam technology, applied in the field of long-span cable-stayed bridge construction, can solve the problems of affecting the construction period, inconvenient measurement of each corner point in sequence, and large dependence on weather, so as to increase the number of monitoring times, save manpower, material resources, and equipment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the drawings.

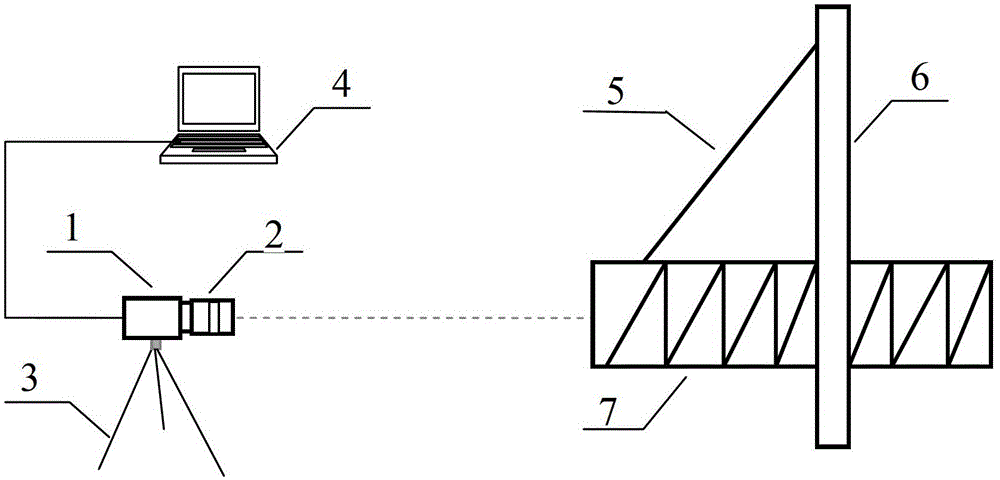

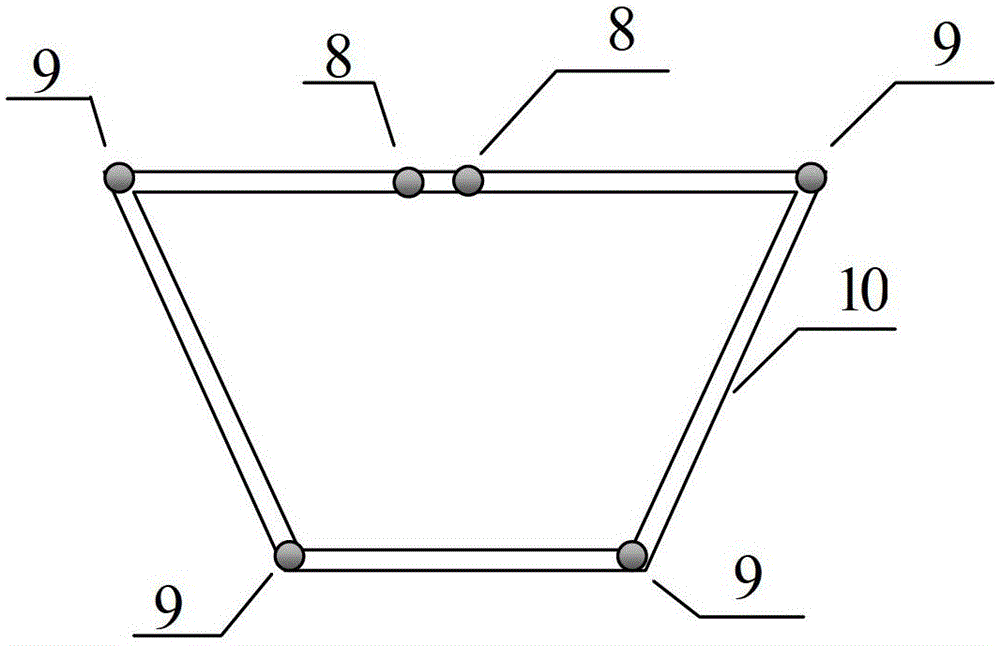

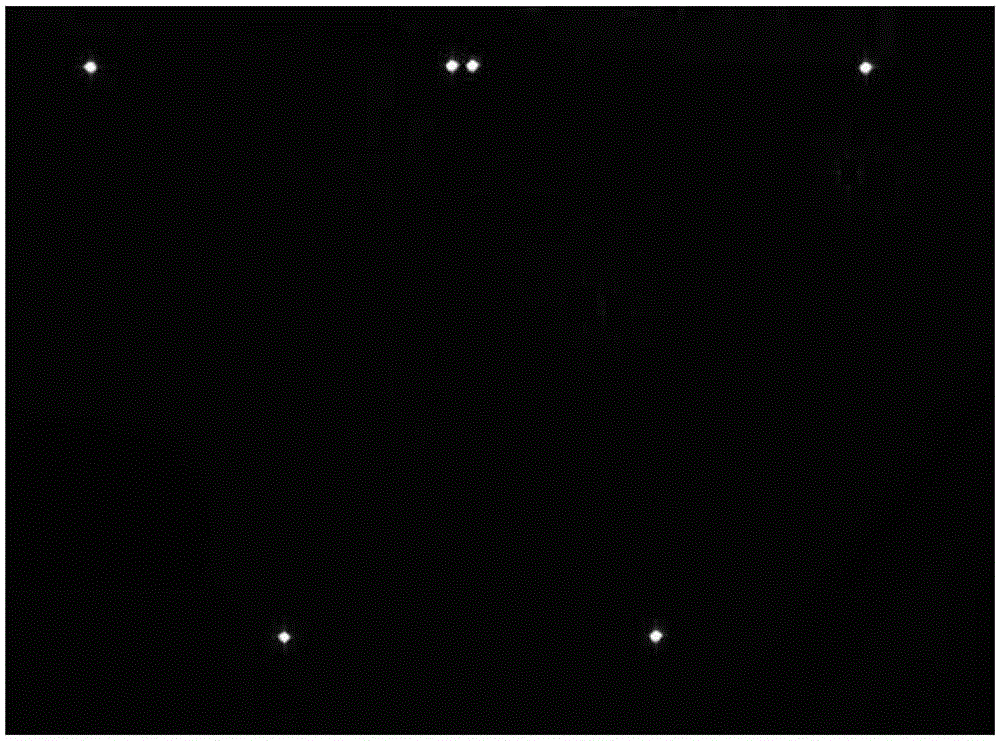

[0031] The method for monitoring the section shape of the steel truss beam during the construction of the long-span cable-stayed bridge of the present invention is achieved by arranging LED lights at each corner of the section of the steel truss beam, or arranging reflectors at each corner of the section of the steel truss beam and matching it with The strong light is projected on the reflector, and then the cross-sectional surface of the steel truss beam is imaged once with the lens and CCD. Each LED light is shown as a bright spot in the image (see image 3 ), using the center of gravity recognition algorithm to calculate the relative coordinate values between the corner points of the steel truss section to achieve the purpose of monitoring the section shape of the steel truss beam during the construction phase, thereby determining whether the section shape of the steel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com