OSM-type circuit breaker contact fitting

A technology for contacting fittings and circuit breakers, applied in the direction of protective switch terminals/connections, etc., can solve problems such as difficult installation, unreliable contact, and inaccessibility, and achieve the effects of convenient installation and maintenance, improved work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

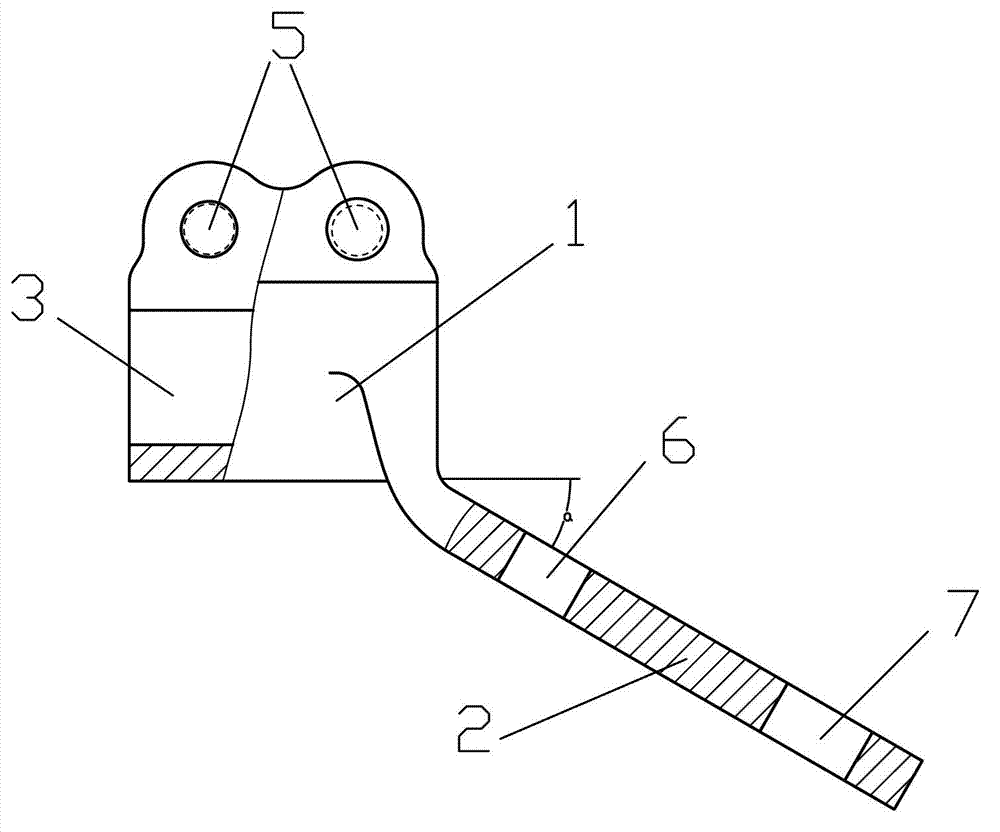

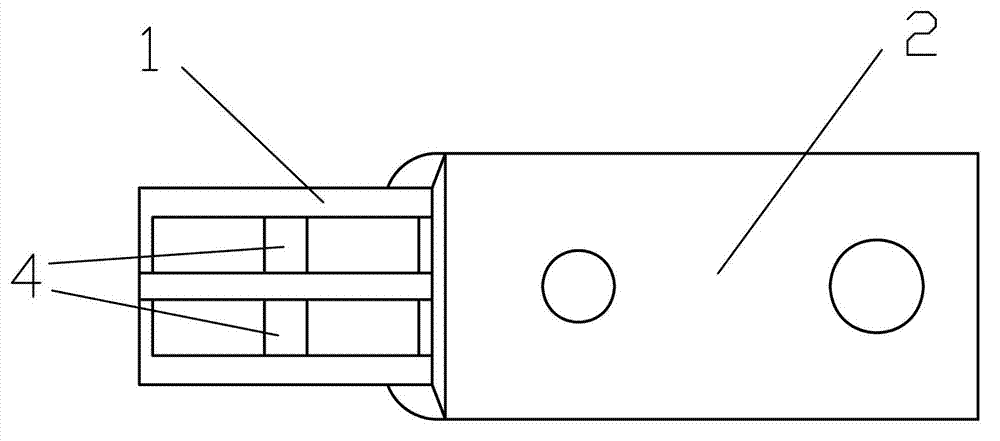

[0018] Such as figure 1 , figure 2 As shown, what this embodiment provides is a contact fitting for an OSM circuit breaker, including a clamp module 1 and a wiring module 2, and the clamp module 1 and the wiring module 2 are integrally manufactured; the clamp module 1 is composed of two One end of the two separation line splints 4 is integrally manufactured to form a merged end, and the other end is suspended and separated into a separate end; the merged end is provided with a first screw hole 3; the wiring module 2 is respectively provided with The second screw hole 6, the third screw hole 7. The included angle between the external extension line of the wire clip module 10 and the wiring module 2 is set at an angle a, and the included angle a is 30°. The separated ends of the two splints 4 are connected by bolts 5 .

[0019] When using an OSM circuit breaker contact fitting provided in this embodiment, first insert the terminal of the OSM circuit breaker into the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com