Protective energy-saving cover for cooking pressure cooker

A technology of pressure cooker and energy-saving cover, which is applied to the shell/sleeve of pressure cooker and cooker, etc., can solve the problems of large exposed area of metal surface, easy to be scalded or scalded, and much heat loss, etc., and achieves low thermal conductivity of air, The effect of shortening the cooking heating time and speeding up the cooking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

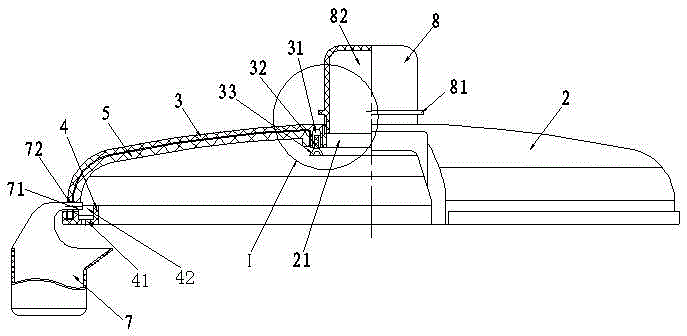

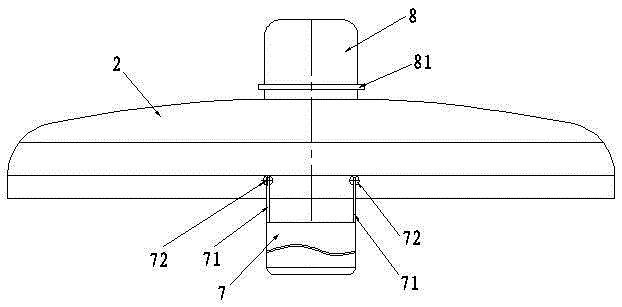

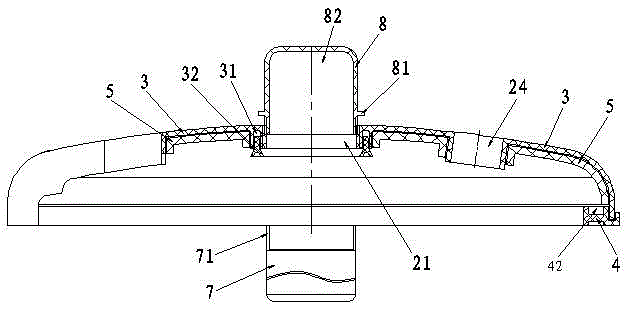

[0026] The protective energy-saving cover of the cooking pressure cooker of the embodiment of the present invention (for the structure see Figure 1 to Figure 7 ), its structural features are: including a shell cover 2 set on the pressure cooker cover 1 for covering its outer surface; the shell cover 2 is composed of a shell 3 and a side cover 4; the shell 3 and the side cover 4 are both made of plastic material;

[0027] The above-mentioned side cover 4 is in the shape of a ring, and its outer peripheral side is closely matched with the inner peripheral side of the lower end of the casing 3, so that the two are tightly fitted and connected to each other; There is an appropriate distance between the peripheral side and the outer peripheral side of the pot cover 1; the inner peripheral side of the side cover 4 is closely attached to the corresponding position of the outer peripheral side of the pot cover 1;

[0028] The above-mentioned shell 3 is provided with a valve position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com