Auxiliary coating device of tail gas catalytic purifier

A technology for catalytic purifiers and auxiliary equipment, which is applied in chemical instruments and methods, coatings, and devices for coating liquid on the surface, etc. It can solve problems such as channel blockage inside the carrier, inconsistent feeding speed, and high viscosity of the active coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

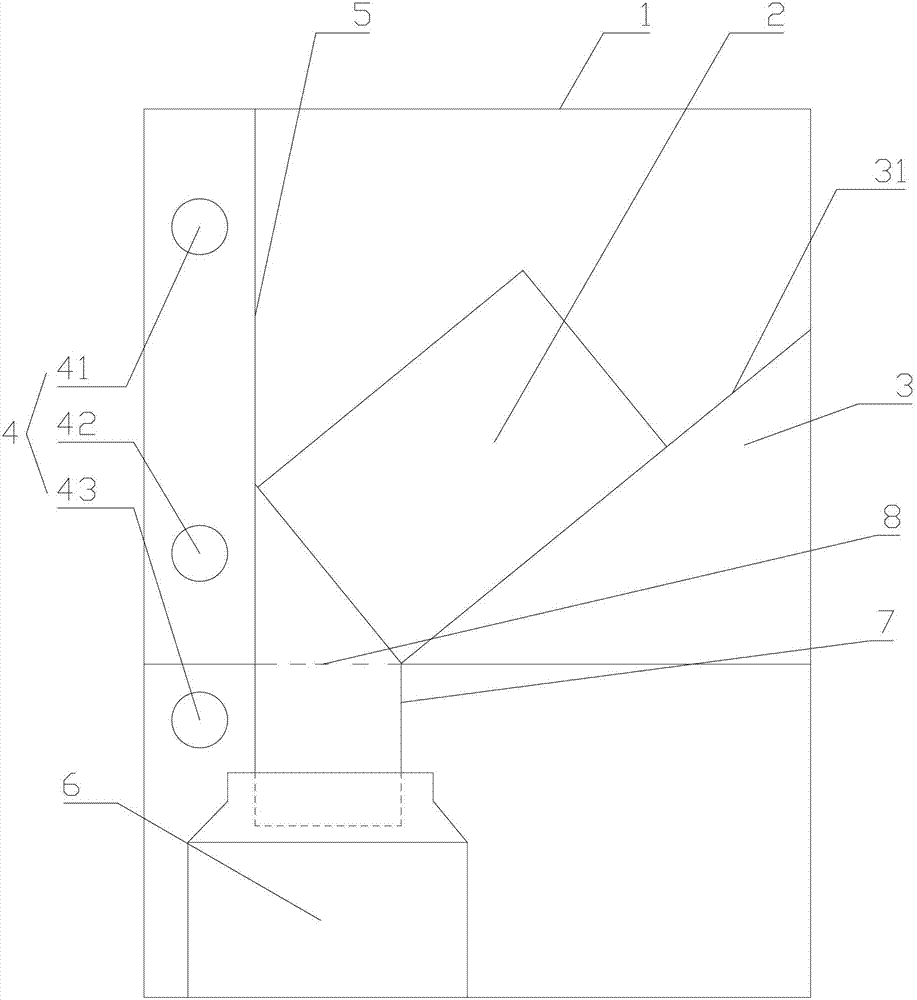

[0016] Such as figure 1 As shown, a kind of tail gas catalytic converter coating auxiliary equipment includes a casing 1, a support platform 3 arranged on the casing for supporting the carrier 2, and a light source 4 arranged on the casing to illuminate the carrier, and also includes supplementary blowing inside the carrier Jammed air gun.

[0017] The support platform is provided with a support surface 31, the angle between the support surface and the horizontal plane is set to 45°, and the support surface is provided with a groove with a cross-sectional shape of an arc for accommodating the carrier. The light source is arranged on the lower side of the supporting platform, and the light source includes a vertically arranged light source 1 41, light source 2 42 and light source 3 43, and the light source 1 is higher than the carrier so that the light irradiates the carrier and its surrounding space , the third light source is lower than the carrier so that the light from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com