Metal spray marking plate special for cold and hot rolling

A hot-rolled coil and metal technology, which is applied in the field of hot-rolled coil special metal spraying plate, cold and hot-rolled coil number spraying device, can solve the problem of large monthly consumption of spraying plate, large consumption of paper materials, It is not easy to grasp the spraying amount and other issues, so as to optimize the efficiency of spraying operations, reduce the consumption of materials and improve the reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

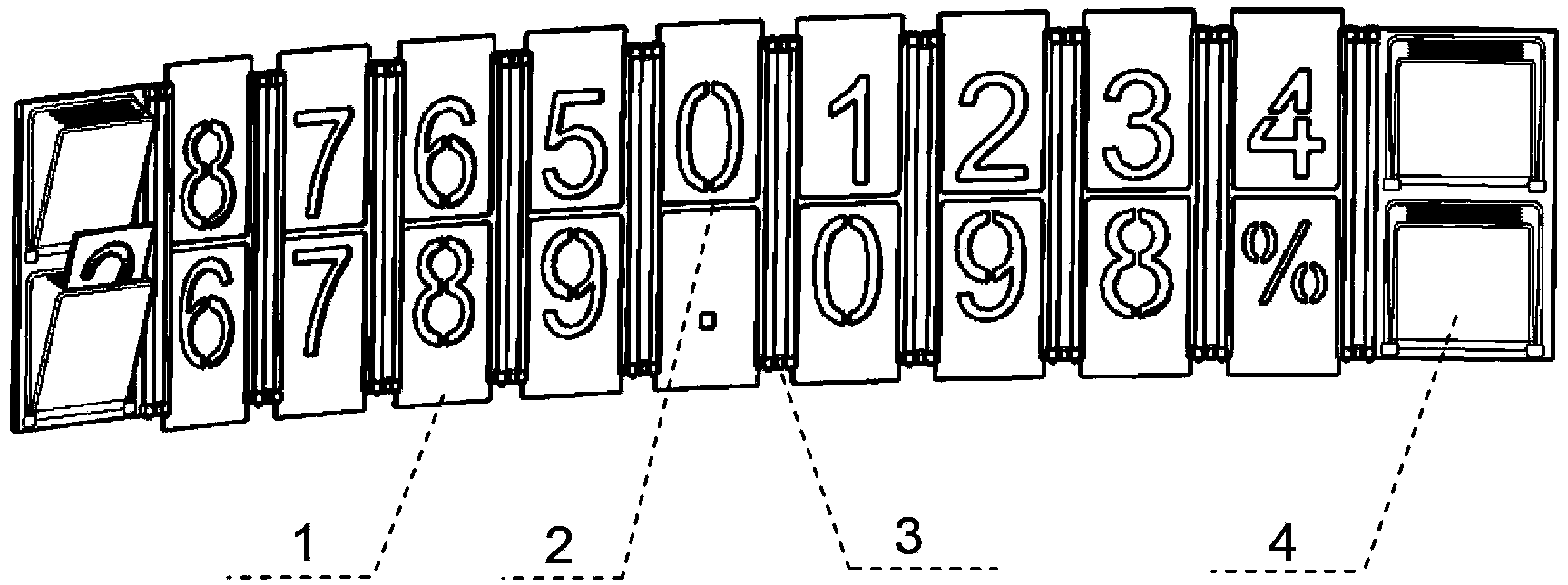

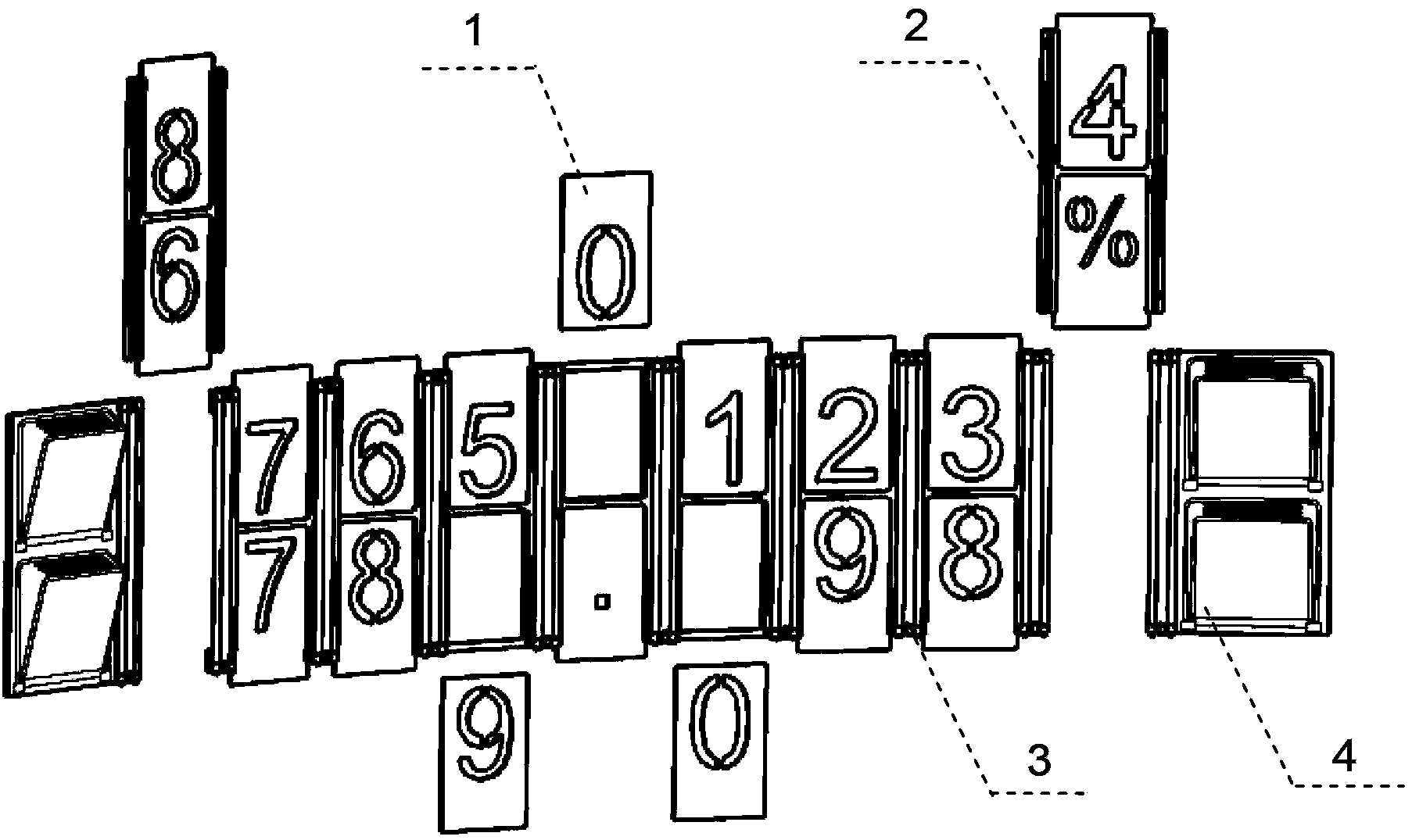

[0033] Please refer to figure 1 and figure 2 , a special metal spraying plate for cold and hot rolled coils, which includes a number plate 1 engraved with numbers, a base plate 2 and a chain shaft assembly 3 for connecting adjacent base plates, and the adjacent base plates are connected in series through the chain shaft assembly.

[0034] like Figure 5 and Image 6 As shown, the substrate 2 is a Japanese-shaped square frame, and the two sides of the square frame have upward inverted T-shaped through grooves a, a' and inner grooves b, b' opened oppositely inward.

[0035] refer to figure 2 and Figure 10 It can be seen that the number plate 1 is a rectangular plate, and its two sides are inserted into the two inward notches of the base plate.

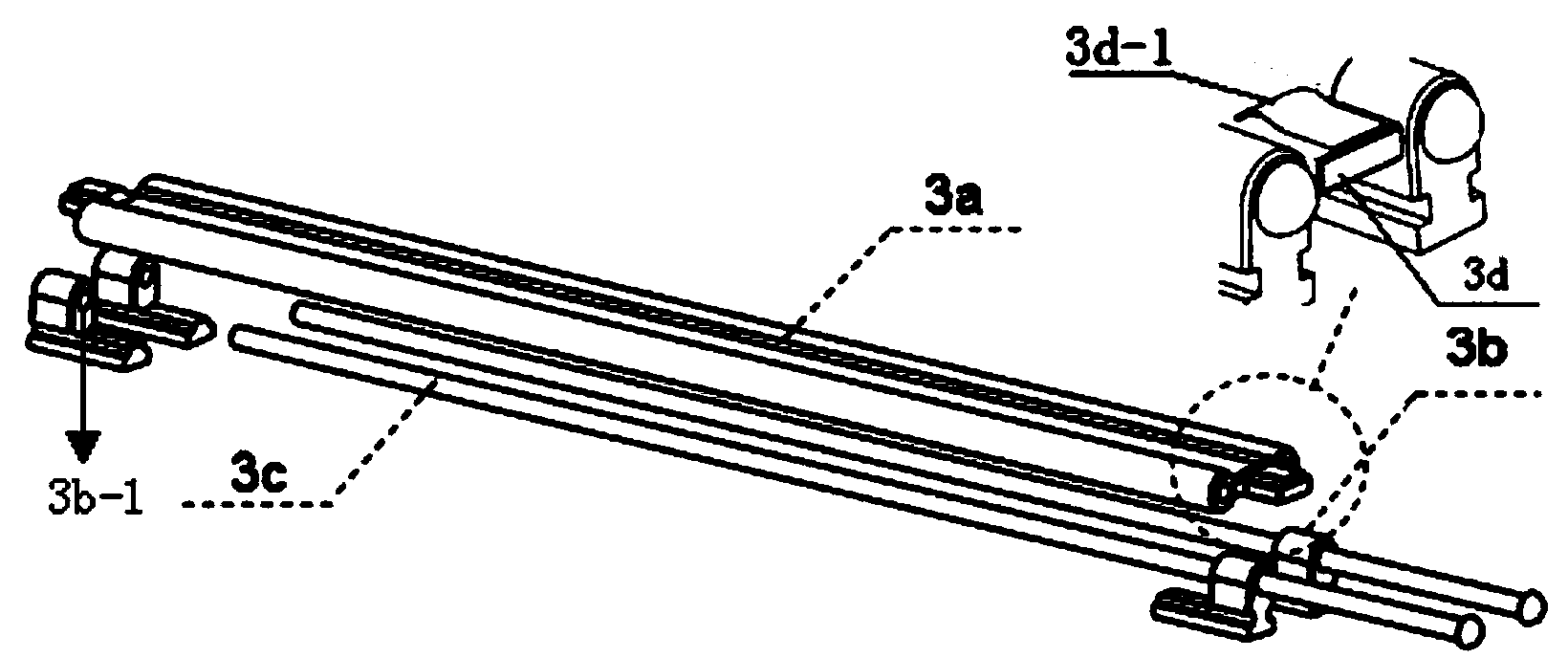

[0036] like image 3 and Figure 4 As shown, the chain shaft assembly 3 includes a double-row connecting shaft 3a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com