Lifting platform system

A technology for raising and lowering platforms and platforms, which is applied in the field of platform systems, can solve problems such as the inability to ensure the same horizontal plane of the platform, troublesome operation, etc., and achieve the effect of convenient operation and enhanced support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

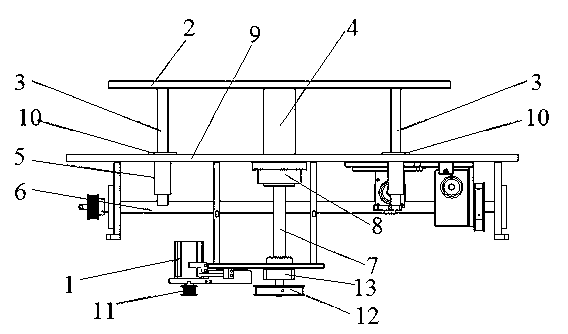

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0015] see figure 1 , The lifting platform system of the present invention includes a motor 1, a transmission mechanism, and a platform 2 for placing workpieces. Among them, the bottom of the platform 2, that is, the bottom surface of the platform 2 is connected with several lifting guide rods 3, and the bottom of the middle of the platform 2 is connected with the lifting shaft 4; the lifting guide rod 3 is sleeved with a linear bearing 5, and the other end of the lifting guide rod 3 Connected with a lifting plate 6, the lifting shaft 4 is connected with a ball screw 7 passing through the lifting plate 6, and the lifting plate 6 and the ball screw 7 are free to lift under the drive of the transmission mechanism driven by the motor 1.

[0016] Further, in order to prevent the lifting guide rod 3 and the ball screw 7 from shaking, a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com