Spinning pack for phenolic resin fiber spinning machine

A technology of phenolic resin fiber and spinneret assembly, which is applied in the field of phenolic resin fiber production equipment, can solve the problems of frequent replacement of spinnerets, easy blockage of through holes of spinnerets, and reduced production efficiency, etc., and achieves easy operation, simple structure, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

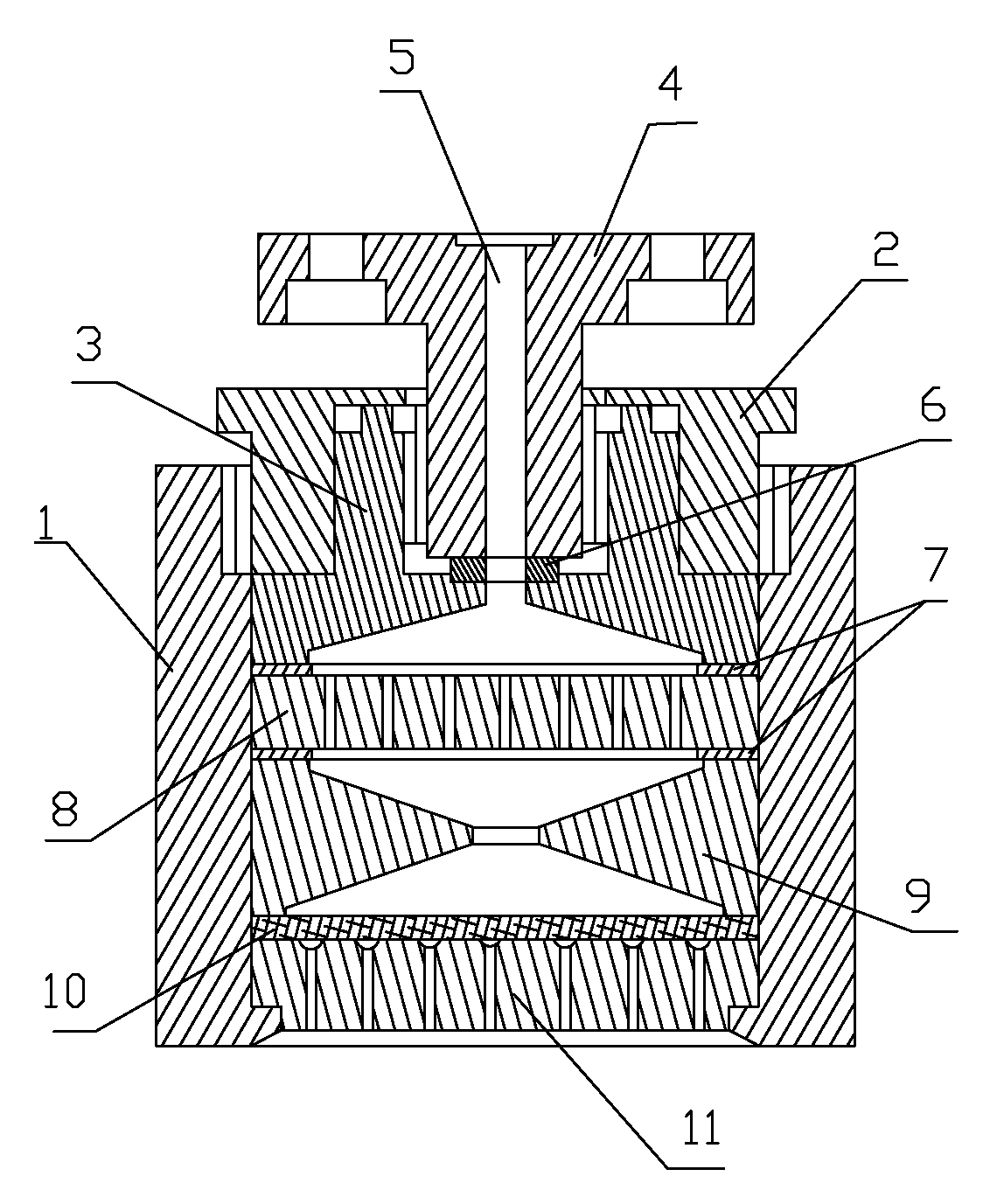

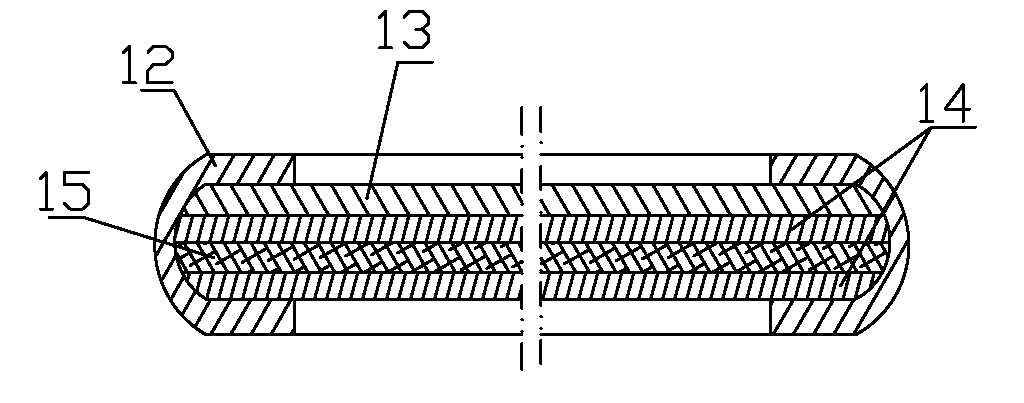

[0017] Refer to attached figure 1 , figure 2 Make the invention. The spinning assembly for the phenolic resin fiber spinning machine includes a housing 1, a connecting seat 4 and a spinneret 11, the housing 1 is cylindrical, the spinneret 11 is provided with a through hole, and the spinneret 11 is located at At the bottom of the housing 1 cavity, the middle part of the connecting seat 4 is provided with a flow channel 5, and the upper end of the connecting seat 4 is fixedly connected to the material nozzle of the spinning machine. It is characterized in that: the spinneret 11 in the housing 1 cavity The upper part is provided with a filter screen 10, a deflector 9, a distribution plate 8, a gland 3 and a fastening screw barrel 2 sequentially from bottom to top, the middle part of the gland 3 is fixedly connected with the lower end of the connecting seat 4, and the fastening screw barrel 2 It is fixedly connected with the upper part of the housing 1, and the flow channel 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com