Push-pull rotational trenching machine

A slotting machine and rotary technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of low efficiency and high equipment construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

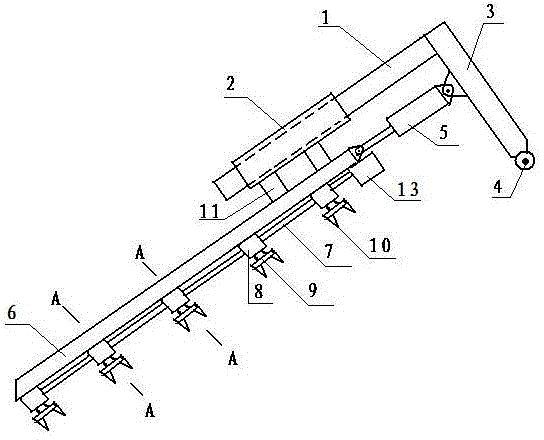

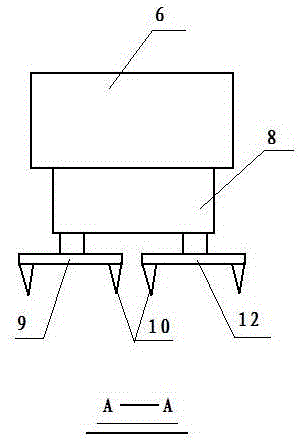

[0012] Accompanying drawing is a kind of specific embodiment of the present invention, and this embodiment column 3 lower end is provided with hinged seat 4, and column upper end is connected with slide bar 1, and slide bar periphery is provided with sliding sleeve 2, and sliding sleeve is fixed on driving by connecting block 11. Rod 6, the right end of the driving rod is hinged to the left end of the driving hydraulic cylinder 5, the right end of the driving hydraulic cylinder is hinged to the column, the lower part of the driving rod is provided with several gear boxes 8, each gear box is connected by a linkage rod, and the lower end of each gear box is provided with a knife Disc A and cutter disc B are provided with a plurality of drill teeth 10 .

[0013] When the present invention is working, the driving motor drives the cutter head A to rotate forward through the linkage rod 7 and the gear box 8, and the cutter head B is reversed. In this way, the drill teeth on the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com