Butterfly helicopter

A helicopter and butterfly technology, applied in the direction of rotorcraft, motor vehicles, aircraft, etc., can solve the problems of poor safety, easy to be attacked by bullets, complicated flight operating system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

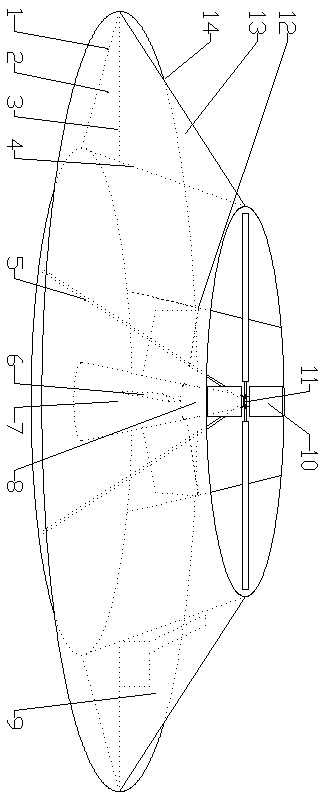

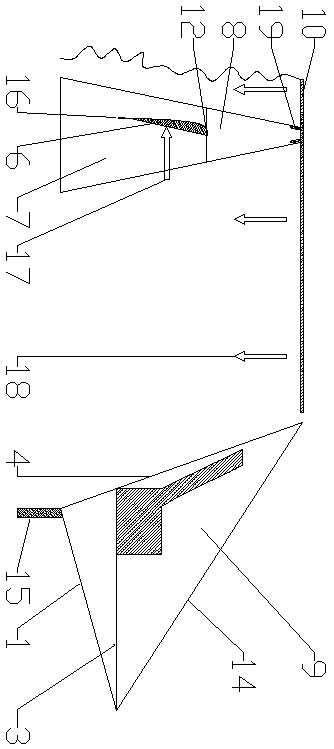

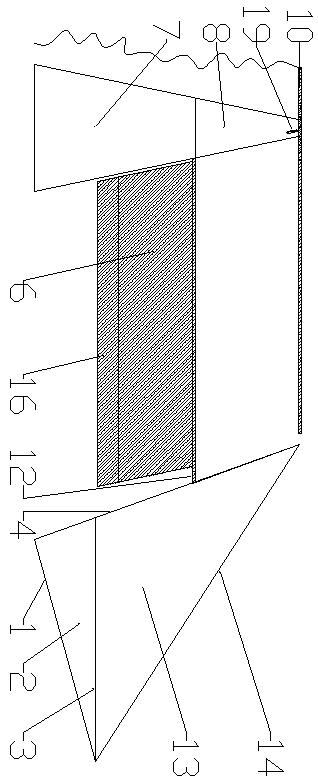

[0012] Such as figure 1 Shown, the rotor 10 is installed on the rotor shaft 11, the outer cover of the rotor shaft 11 is the engine conical radiator 8, below is the engine and transmission conical shell 7, surrounded by the lower cone 1, the upper cone 14 and the inner cone The body 4 constitutes a butterfly cabin, the butterfly cabin and the motor conical radiator 8 are movably connected by three cables 12, and the middle part is connected by three hydraulic rods 12 and the conical shell 7 of the engine and transmission, and the outside of the hydraulic rod 12 is a wing plate 6 , the lower part of the wing plate is the flap 16, such as figure 2 As shown, the rotor 10 produces a downward airflow 18 counterclockwise, and the two sides of the wing plate 6 and the flap 16 produce a clockwise horizontal thrust 17 on the wing plate due to the difference in the speed of the curved surface and the plane airflow on both sides of the flap 16, and the angle of the flap 16 can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com