Internal clamping type lock

An inner pliers and pliers technology, applied in the field of inner pliers locks, can solve problems such as the inability to be firm and reliable in the anti-prying performance of straight-bolt locks, and achieve the effects of superior anti-damage performance, high mechanical strength and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail by the following examples.

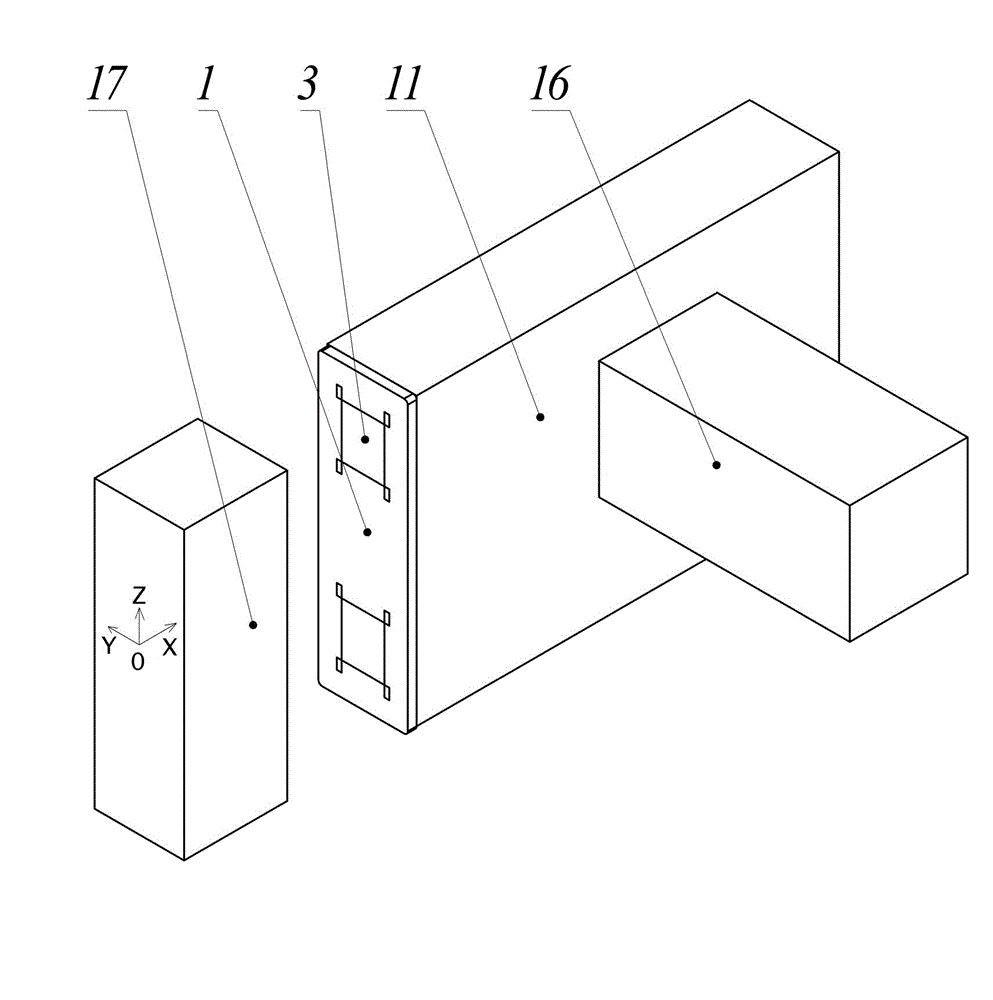

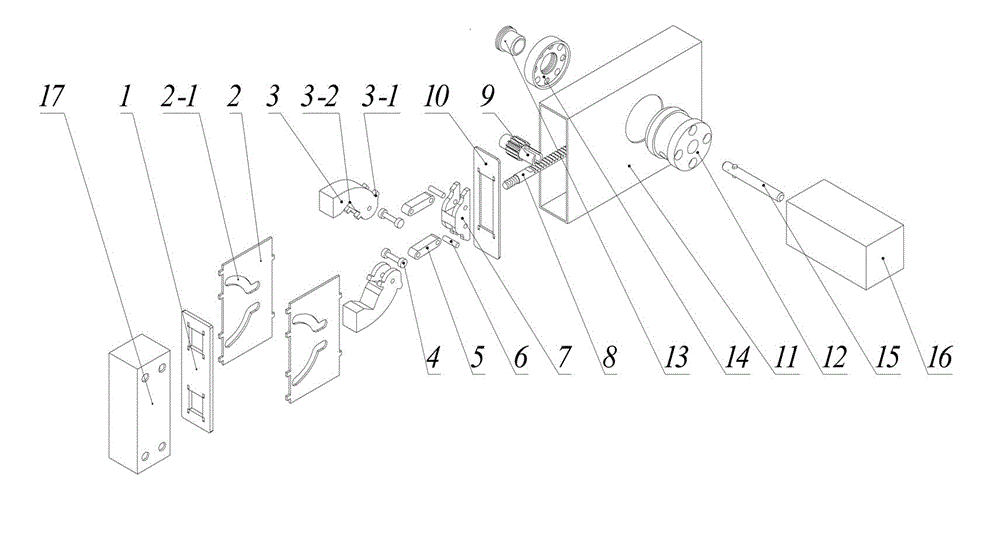

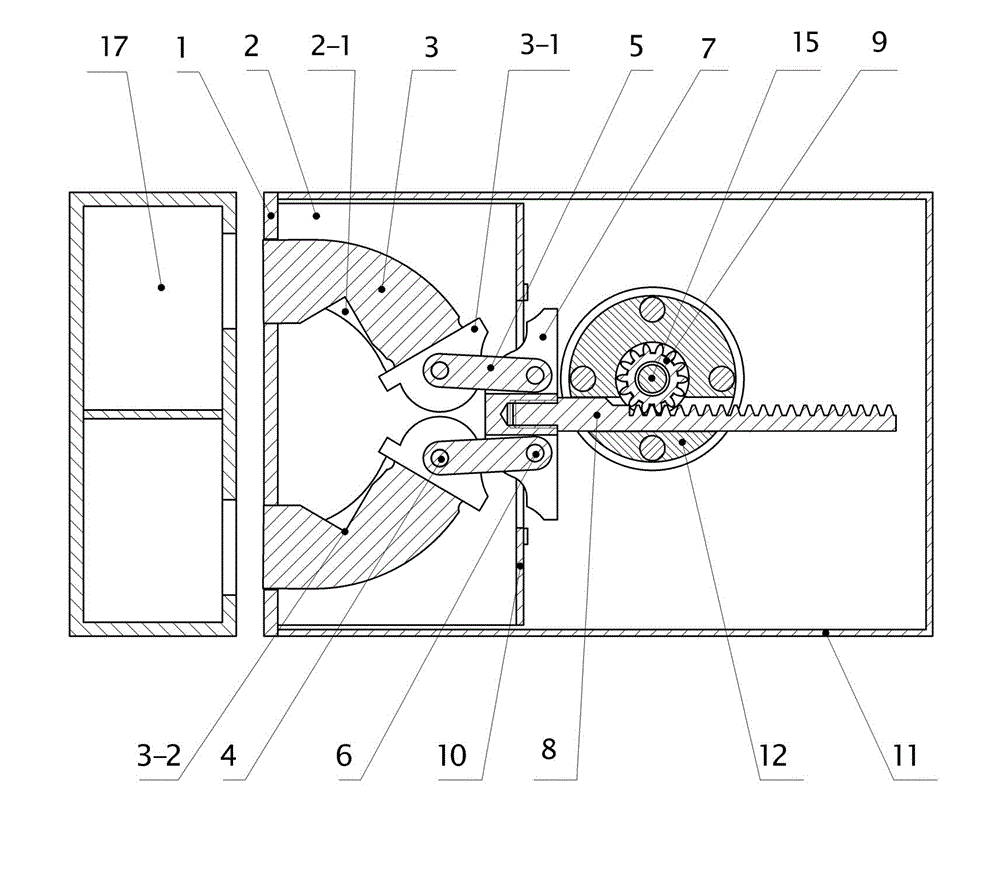

[0016] see figure 1 -- Figure 4 As shown, a kind of internal pincer type lock is made up of lock box 11, snap box 17, rack and pinion fixing device, unlocking power mechanism 16, power transmission shaft 15 and internal pincer type dead bolt kinematic mechanism. The lock box 11 is fixed on one side of the double door, and the lock box 17 is fixed on the other side of the door and corresponds to the lock box 11. The rack and pinion fixing device is composed of a rack 8, a gear 9, a rack and pinion fixing seat 12, a fixing seat locking ring 14 and a gear limit ring 13, and the horizontally placed rack 8 passes through and is slidably supported on the rack and pinion seat 12. The gear 9 is placed in the central hole of the rack and pinion seat 12 and meshed with the rack 8. The rack and pinion seat 12 is fixed in the lock box 11 through the locking ring 14 of the fixing seat, and the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com