Plastic bottle infusion preparations with various specifications of the same bottle type microporous inspection machine outlet bottle clamping mechanism

A technology for plastic bottles and inspection machines, which is applied in directions such as detecting the presence of fluid at the leak point and measuring the liquid tightness using liquid/vacuum, which can solve the problems of unsuitable packaging bottles and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the drawings and examples.

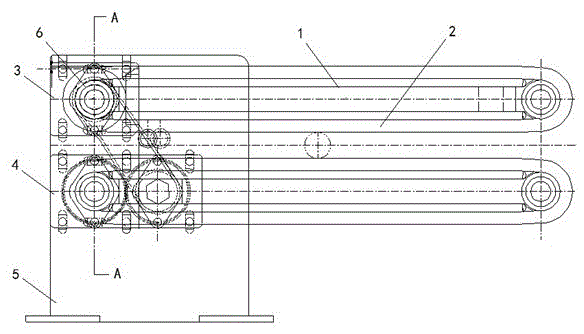

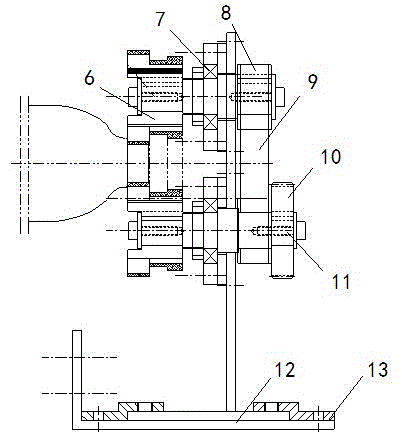

[0025] figure 1 It is a structural schematic diagram of the bottle-clamping mechanism at the outlet of the bottle-type microporous inspection machine with various specifications of plastic bottle infusion preparations of the present invention; figure 2 is along figure 1 Sectional view of line A-A. Such as figure 1 and figure 2 As shown, the plastic bottle infusion preparation of the present invention has various specifications and the bottle clamping mechanism at the outlet of the bottle-type microporous inspection machine, including a base 12 and a conveying fixture supported by a support plate 5 connected to the base. A pressing plate 13 is arranged on the base 12 . The support plate 5 is divided into an upper support plate 3 and a lower support plate 4 . The conveying fixture comprises a bottle clamping bar 1 symmetrically arranged up and down, a bottle clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com