Heat storage body, heat storage structure, forming mold and manufacturing method thereof

A technology for forming molds and heat storage bodies, which is applied to heat storage equipment, heat exchanger types, indirect heat exchangers, etc. Heat rate, less clogging, effect of increasing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

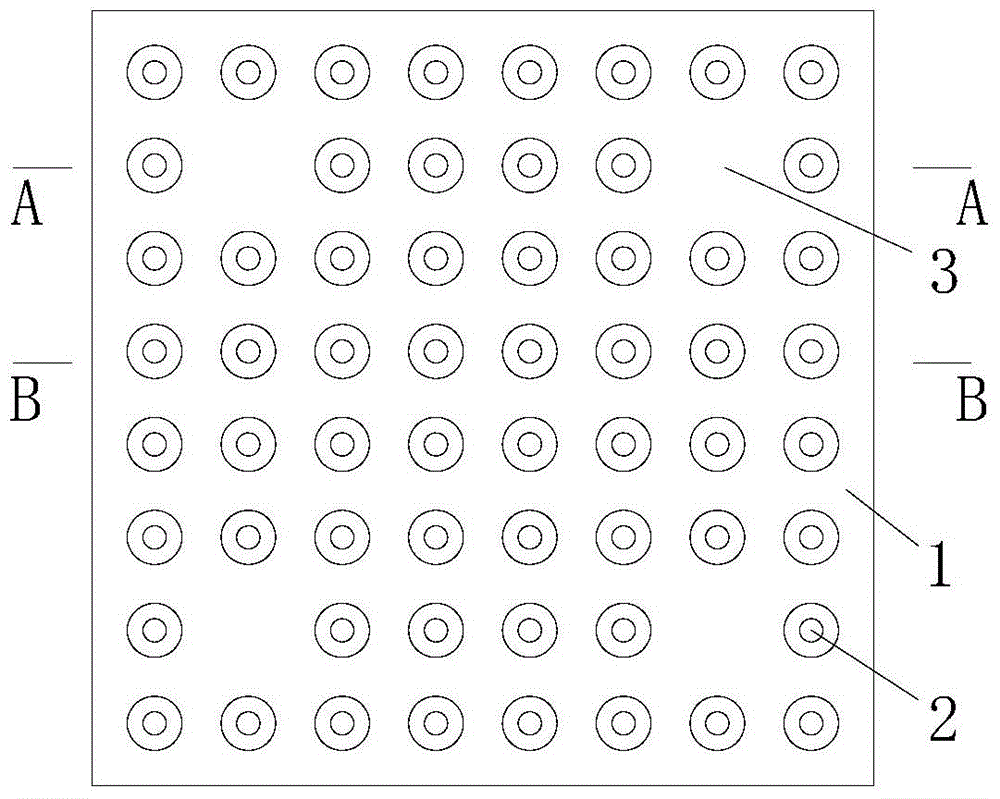

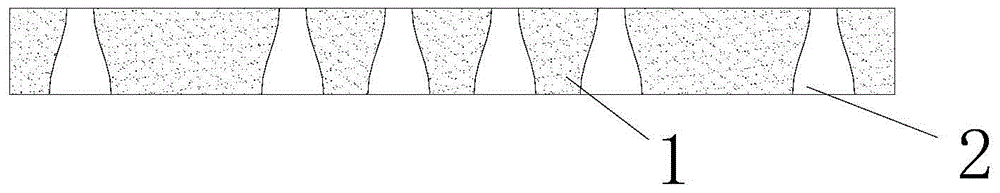

[0040] A heat storage body, including a heat storage body 1, on which a number of zoom-type fluid channels 2 are opened, and the wall surface profile of the zoom-type fluid channels 2 is at least two segments of arcs and between arcs The shape formed by the generatrix composed of the tangent lines between them is rotated around the central axis for one circle, or it is a variable-diameter channel with circular and smooth changes in diameter. Like a bottleneck.

[0041] The specific structure of the variable diameter channel is a circular variable diameter channel whose diameter increases smoothly from small to large and then smoothly decreases from large diameter. Preferably, the busbar is a streamline that changes smoothly. Preferably, the diameters of the two ports of the zoom-type fluid channel 2 are large and small, and the diameter of the zoom-type fluid channel 2 between the large and small ports transitions smoothly from large to small. Specifically, the radius of the ...

Embodiment 2

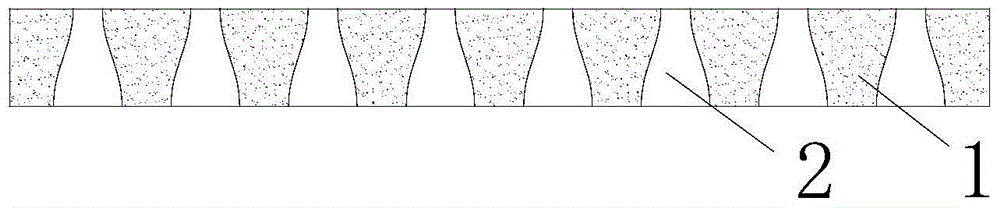

[0046] A thermal storage structure formed by stacking two or more heat accumulators described in Embodiment 1. The two stacked thermal accumulators are connected to each other to form a smooth long-scale fluid channel 2 aisle. Preferably, the ports of the same diameter of the overlapping two regenerator zoom-type fluid channels 2 are connected correspondingly.

[0047] Working process and working principle of the present invention: heat accumulators are stacked in a certain order to form a continuous streamlined or wavy long-scale fluid channel, and the gas flows through the long-scale fluid channel with alternating flow rates Changes, forming a certain turbulent eddy flow, the particles in the gas are not easy to deposit and block the channel, which can significantly increase the gas-solid surface heat transfer rate between the gas and the regenerator, and because the wall of the long-scale fluid channel is streamlined Or wavy smooth change, so the increase of flow resistanc...

Embodiment 3

[0050] A regenerator forming mold for manufacturing a regenerator described in Embodiment 1, comprising an upper template 4, an upper mold holder 5, a punch 6, a lower mold holder 7 and a demoulding mechanism, the lower mold holder 7 There is a cavity on the top, the upper template 4 is fixed with the upper mold base 5, the punch 6 is nested on the upper mold base 5, the forming part of the punch protrudes from the upper mold base 5, and the demoulding mechanism is connected to the lower mold base 7 superior.

[0051] Because there are many zoom-type fluid passages 2, it is difficult to process many punches 6 with very small spacing on a steel block. Therefore, the present invention firstly processes the punch 6, the upper template 4 and the upper die holder 5 respectively. Then, the punch 6 is embedded in the upper mold base 5, and finally the upper mold 4 is used to compress the punch 6, and the upper mold 4 and the upper mold base 5 are fastened into one body with bolts, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com