Automatic dehydration apparatus and method for waste oil

A dehydration device and gutter oil technology, applied in separation methods, chemical instruments and methods, dehydration/emulsification by mechanical methods, etc., can solve the problem that oil sludge and slag cannot be removed in time, increase the difficulty of oil-water separation, and thicken the oil-water interface and other problems, to achieve the effect of improving the oil-water separation effect, facilitating continuous and stable work, and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

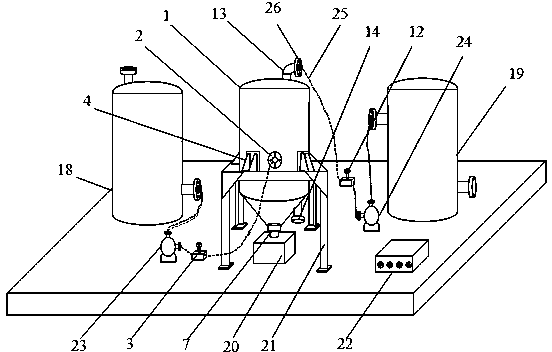

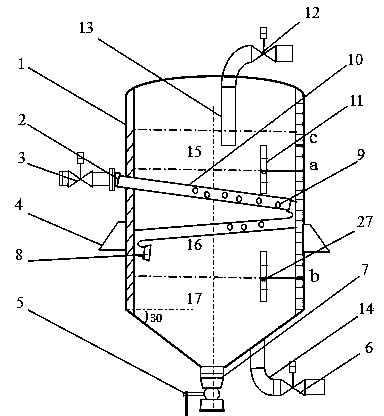

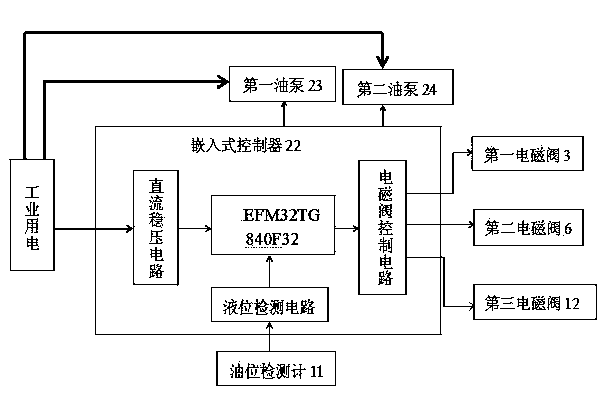

[0018] see figure 1 , the present invention includes dehydration tank 1, former waste oil storage tank 18, dehydration waste oil storage tank 19, sludge tank 20 these four tank bodies. Among them, the dehydration tank 1 is an integrated tank body formed by seamless welding of the tank roof, tank wall and tank bottom. The tank roof adopts a self-supporting ribbed spherical shell vault structure, which has good bearing capacity and light weight. . The top of the dehydration tank 1 is provided with an oil outlet, and one end of the dehydration oil suction pipe 13 extends into the inside of the dehydration tank 1 through the oil outlet on the top of the dehydration tank 1, and the other end of the dehydration oil suction pipe 13 stretches out of the dehydration tank 1 and One end of the oil delivery pipe 25 is connected by a flange 26, and the other end of the oil delivery pipe 25 is connected to the dewatered waste oil storage tank 19. A third electromagnetic valve 12 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com