Large-volume garlic mashing device adopting manual pressing garlic cutting and squeezing

A large-capacity garlic paste technology, which can be used in home appliances, household machinery for filtering food, and other applications. It can solve the problems of automatic extrusion of garlic paste and poor garlic pressing effect, and achieve good results, fast pressing, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

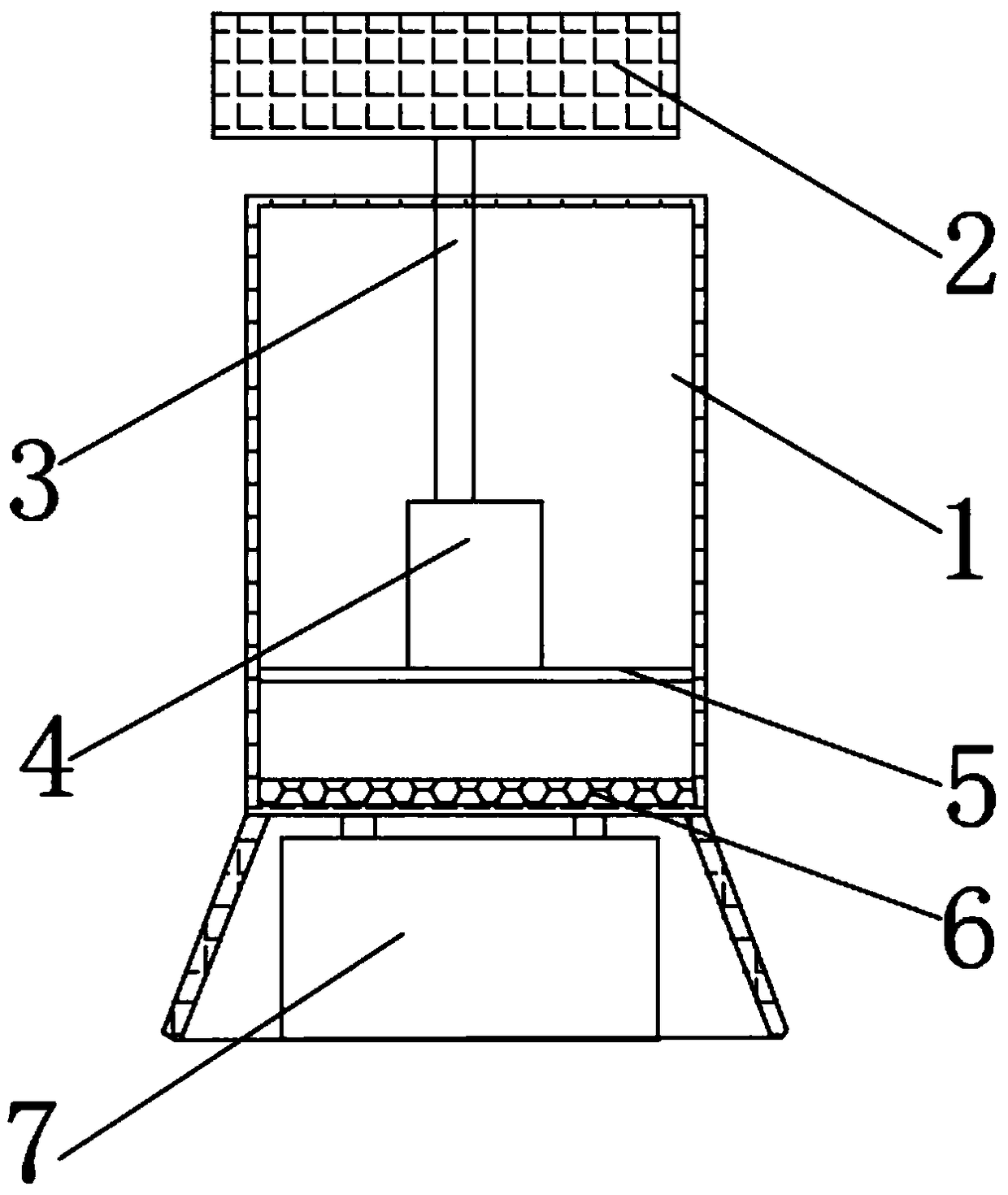

[0027] Such as Figure 1-5 As shown, a large-capacity hand pressing, cutting and extrusion type garlic mash device includes a main body 1 of the mashed garlic device, and the main body 1 of the mashed garlic device includes a pressing device 2, a pressing rod 3, a pneumatic device 4, a sieve plate with a knife 6 and a mashed garlic bowl 7 , the upper end of the pressing rod 3 is fixedly connected with the pressing device 2, and the lower end of the pressing rod 3 is fixedly connected with the pneumatic device 4, the lower end of the pneumatic device 4 is fixedly installed with the pressing plate 5, and the sieve plate 6 with the knife is fixed Installed directly below the pressing plate 5, the mashed garlic bowl 7 is movably placed under the sieve plate 6 with a knife,

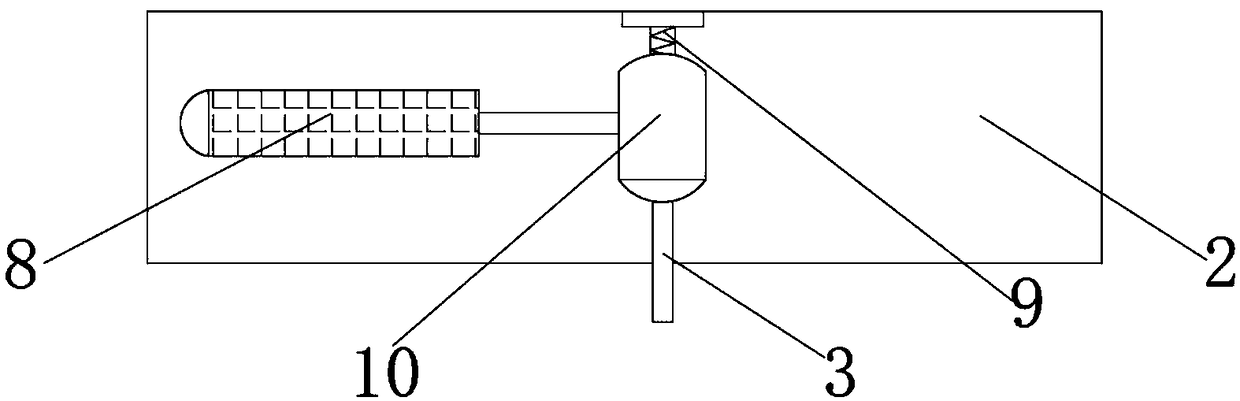

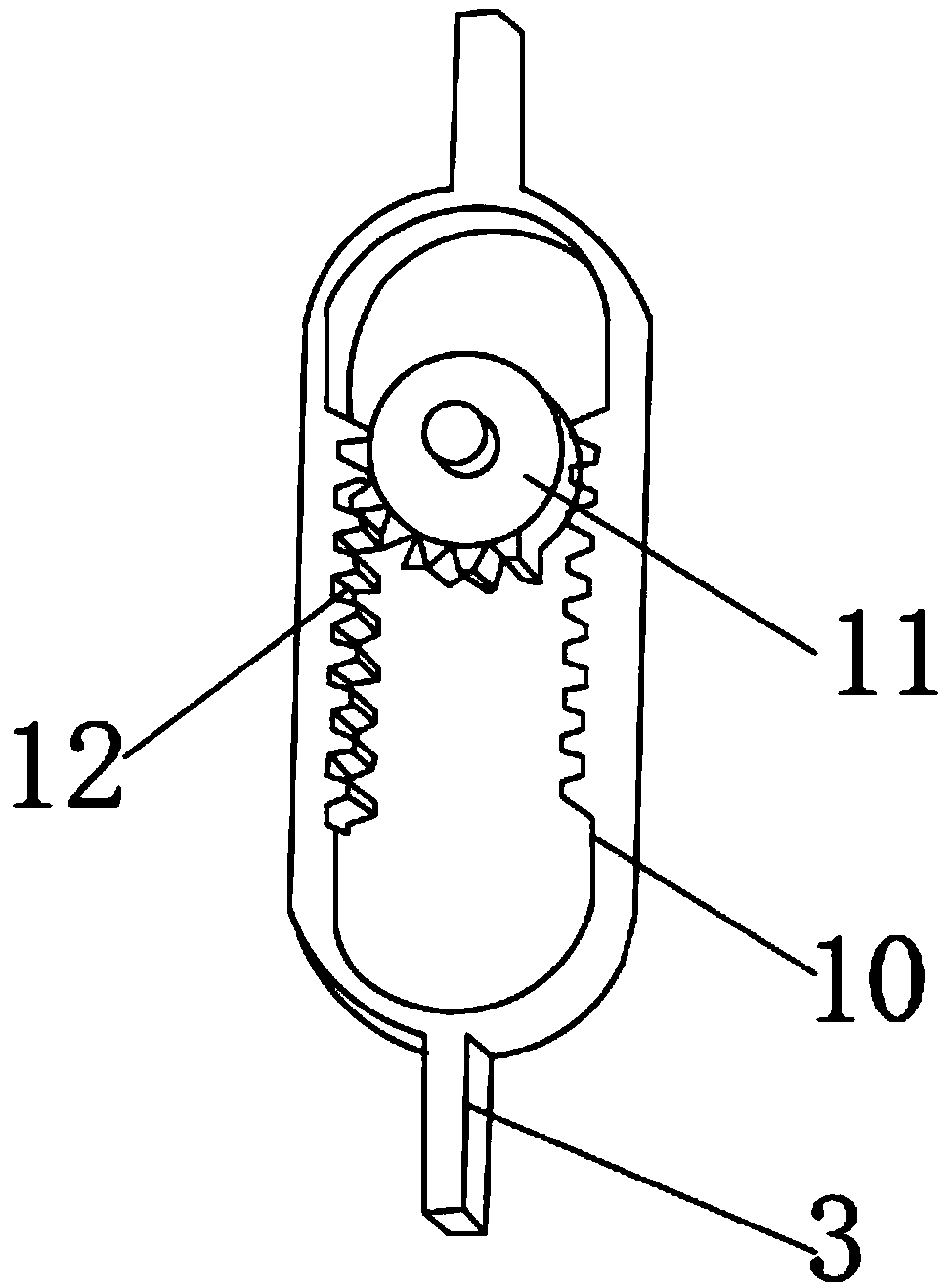

[0028] The pressing device 2 includes a motor 8, an intermittent transmission mechanism 10 and a spring 9, the output shaft of the motor 8 is fixedly connected to the intermittent transmission mechanism 10, an...

Embodiment 2

[0035] Such as Figure 1-5 As shown, a large-capacity hand pressing, cutting and extrusion type garlic mash device includes a main body 1 of the mashed garlic device, and the main body 1 of the mashed garlic device includes a pressing device 2, a pressing rod 3, a pneumatic device 4, a sieve plate with a knife 6 and a mashed garlic bowl 7 , the upper end of the pressing rod 3 is fixedly connected with the pressing device 2, and the lower end of the pressing rod 3 is fixedly connected with the pneumatic device 4, the lower end of the pneumatic device 4 is fixedly installed with the pressing plate 5, and the sieve plate 6 with the knife is fixed Installed directly below the pressing plate 5, the mashed garlic bowl 7 is movably placed under the sieve plate 6 with a knife,

[0036] The pneumatic device 4 includes a cavity 15, a piston rod 14, a piston 16 and a valve 17, the upper end of the piston rod 14 is fixedly connected with the pressure rod 3, and the lower end of the piston...

Embodiment 3

[0039] Such as Figure 1-5 As shown, a large-capacity hand pressing, cutting and extrusion type garlic mash device includes a main body 1 of the mashed garlic device, and the main body 1 of the mashed garlic device includes a pressing device 2, a pressing rod 3, a pneumatic device 4, a sieve plate with a knife 6 and a mashed garlic bowl 7 , the upper end of the pressing rod 3 is fixedly connected with the pressing device 2, and the lower end of the pressing rod 3 is fixedly connected with the pneumatic device 4, the lower end of the pneumatic device 4 is fixedly installed with the pressing plate 5, and the sieve plate 6 with the knife is fixed Installed directly below the pressing plate 5, the mashed garlic bowl 7 is movably placed under the sieve plate 6 with a knife,

[0040] The lower surface of the press plate 5 is evenly fixed with bumps 13, and the bumps 13 are spherical; the bumps 13 on the lower surface of the press plate 5 correspond to the positions of the holes of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com