Permanent magnet synchronous motor anti-demagnetization control method

A technology of permanent magnet synchronous motor and control method, applied in the direction of electronic commutation motor control, control system, electrical components, etc., can solve the problems of high motor speed, hindering the popularization of new energy vehicles, and instantaneous peak current impact of motor windings. The effect of reducing rare earth content, reducing the risk of demagnetization, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

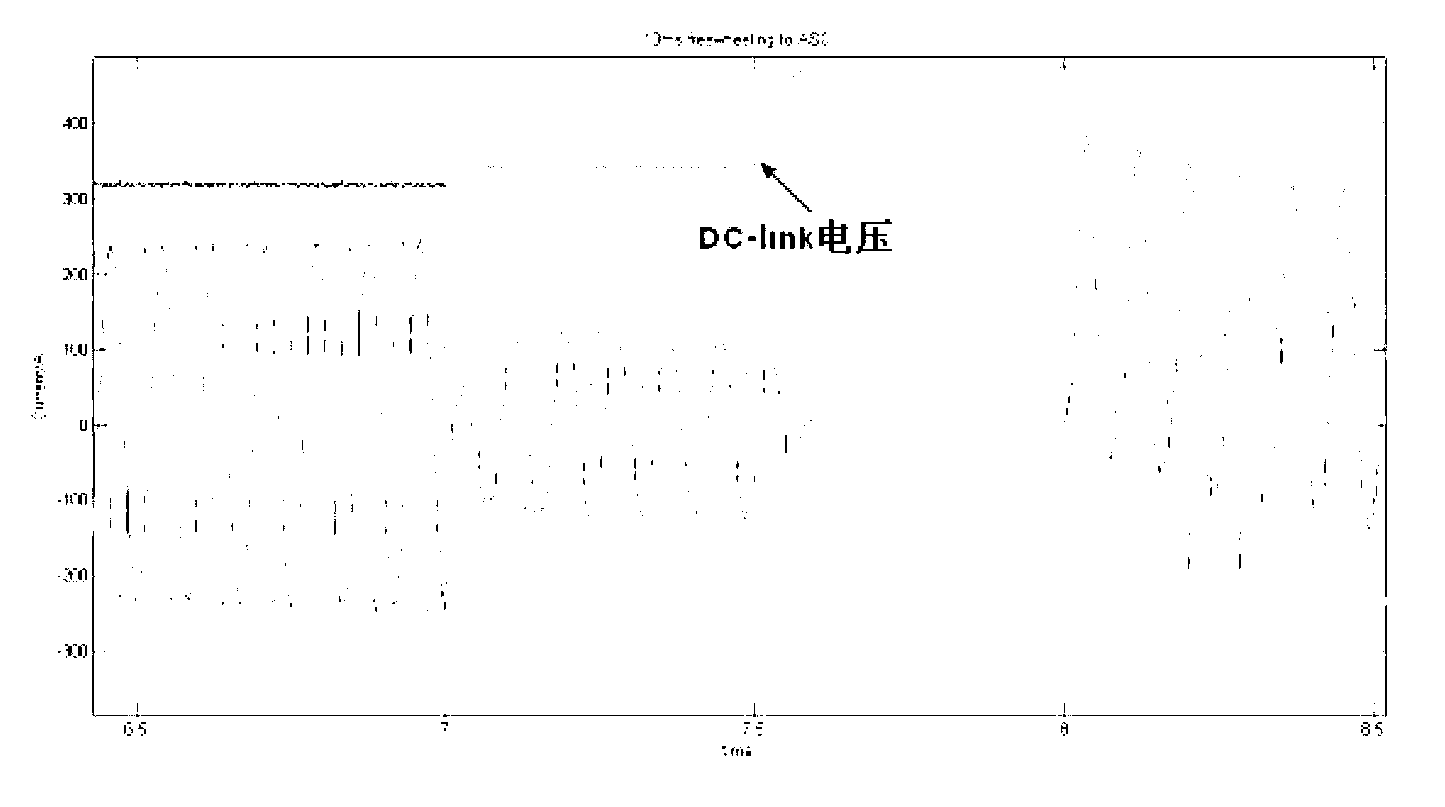

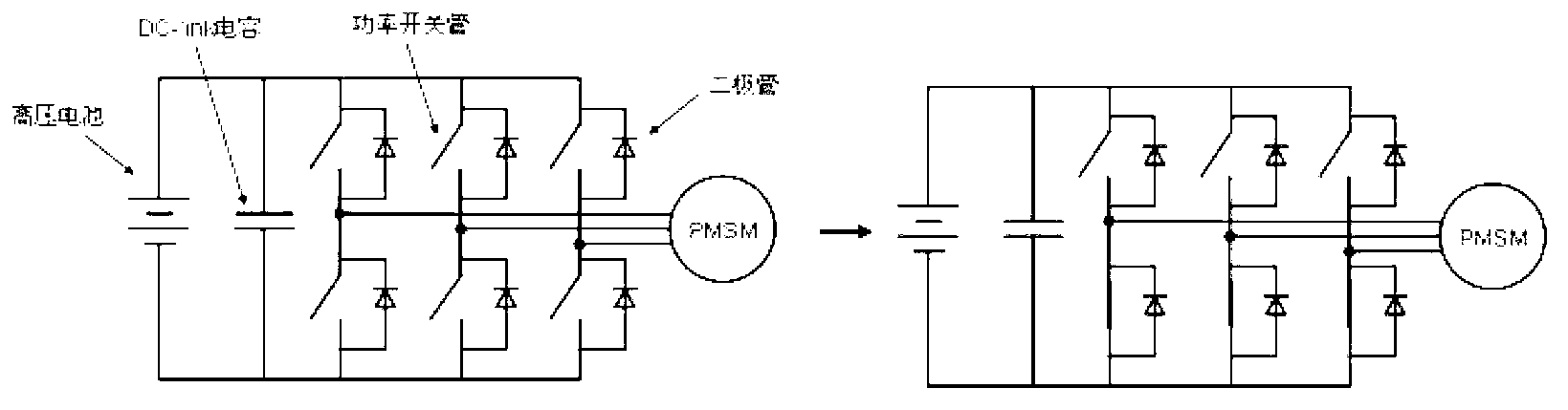

[0025] The control method for suppressing the demagnetization rate of the permanent magnet synchronous motor for new energy vehicles described in the present invention can reduce The instantaneous peak current generated by the original method prevents or reduces the risk of demagnetization of the permanent magnet steel of the motor. Therefore, in the design of the motor, the magnetic circuit design can be carried out based on the reduced instantaneous peak current, and the magnetic steel with a lower coercive force can be selected to reduce the content of rare earths and achieve the purpose of reducing costs.

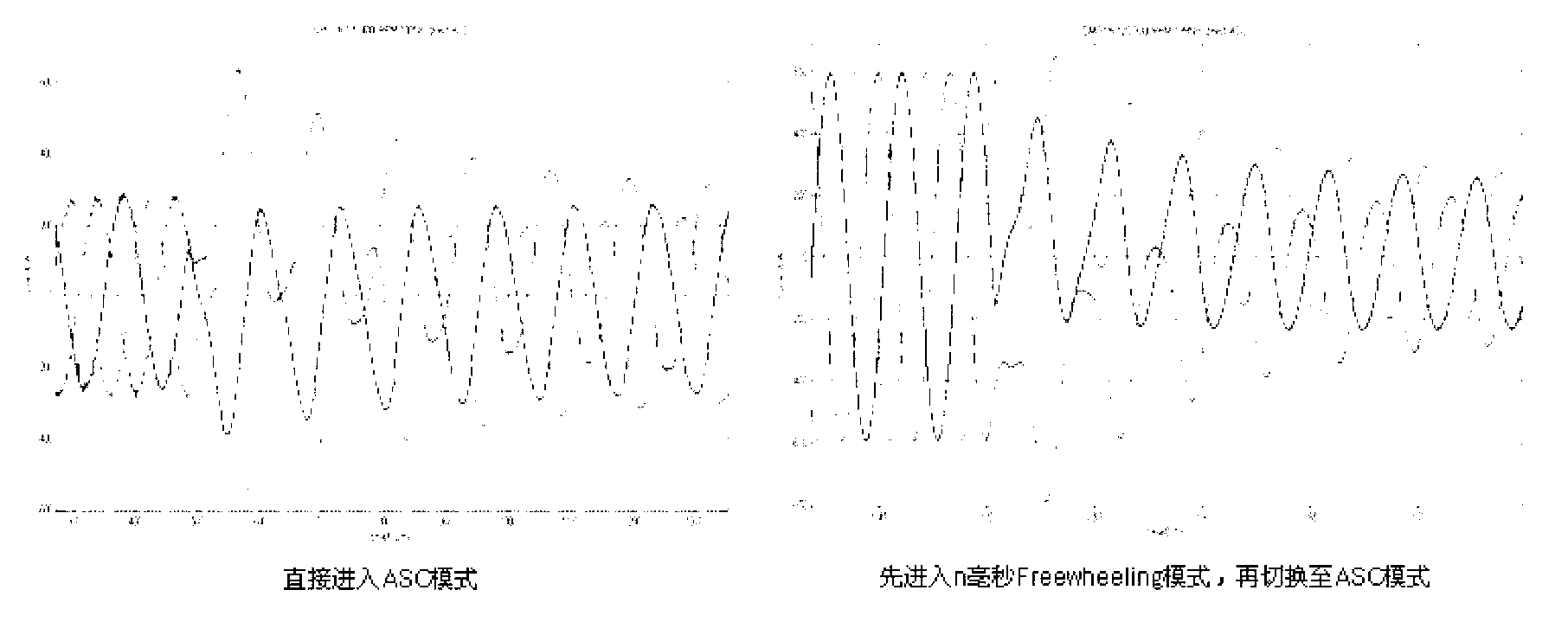

[0026] The control method described in the present invention is: if the motor is running in the low and medium speed range (less than TBD% of the maximum speed, the TBD value can be matched according to the actual application), the system fails, such as detecting that the motor phase current exceeds the threshold. At this time, the controller responds to the failure, fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com