Device for corrugating a metal tube

A technology of metal pipes, equipment, applied in the field of equipment for making metal pipes into waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

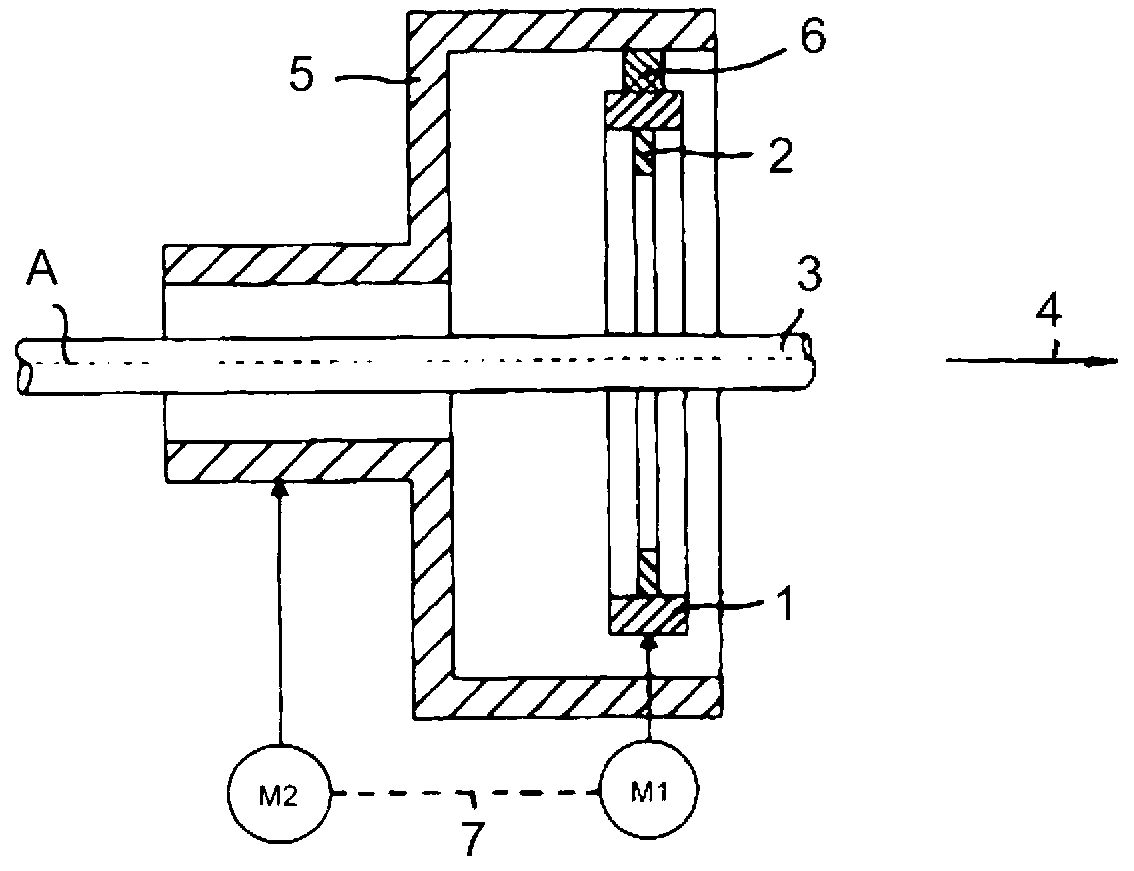

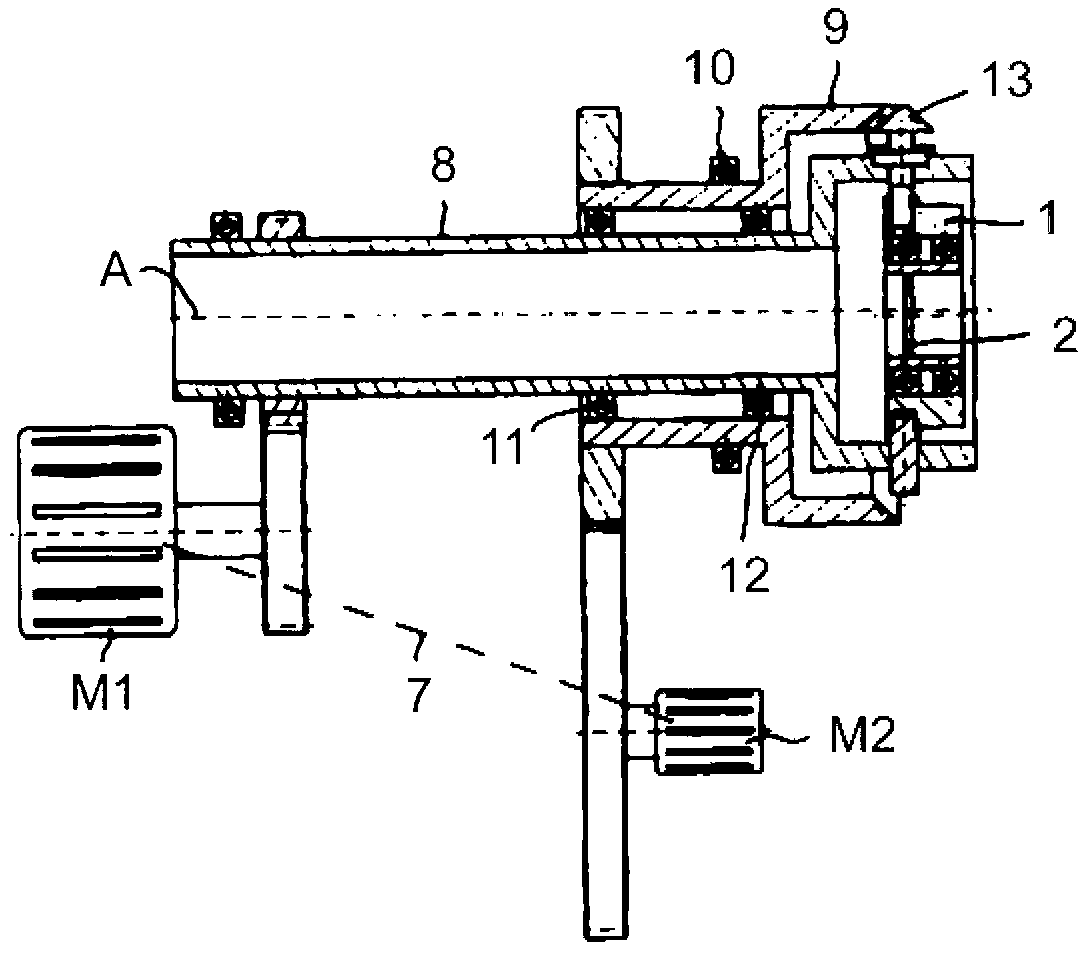

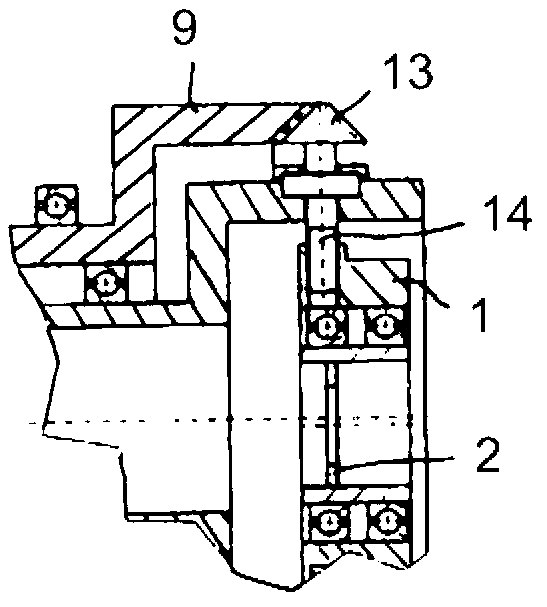

[0016] figure 1 A ring-shaped corrugator 1 is shown, which is rotatable about its axis and is driven for this purpose by a first electric motor M1 (hereinafter referred to as "motor M1"). A likewise ring-shaped bellows plate 2 protruding radially inwards from the bellows head 1 is accommodated in the bellows head 1 , preferably made of stainless steel. The corrugation platen can be adjusted radially within the corrugation head 1 and is used to imprint wave valleys on the metal tube 3 which is drawn through the corrugation head 1 , for example in the direction of the arrow 4 . The bellows plate 2 is eccentrically installed in the bellows head 1 . When the equipment is working, the corrugated pressure plate 2 surrounds or rolls on the pipe 3 in the circumferential direction. The tube 3 can be produced, for example, from copper or aluminum or alloys of these materials or from steel, especially stainless steel.

[0017] The corrugated pressure plate 2 can be designed as a smoot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap