Double roll lead belt forming machine

A technology of forming machine and lead strip, applied in the field of counter-roll lead strip forming machine, can solve the problems of reduced production flexibility, easy contamination of cooling liquid, spray influence, etc., and achieves improved production flexibility, appearance quality assurance, cooling mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

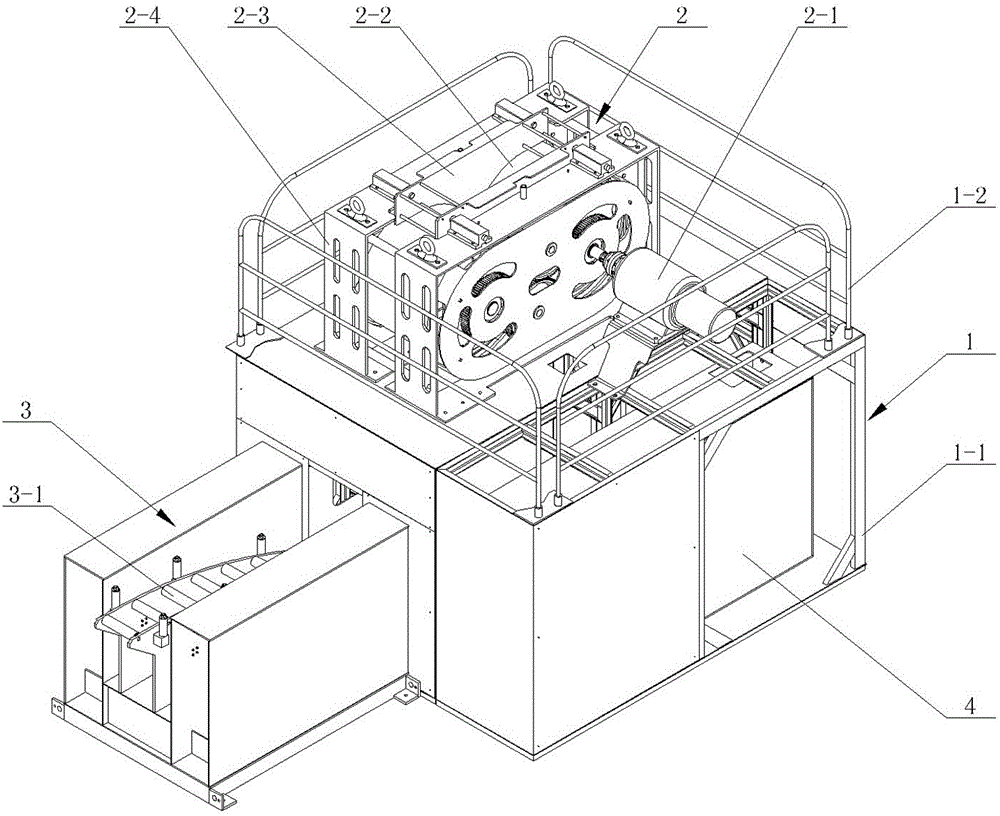

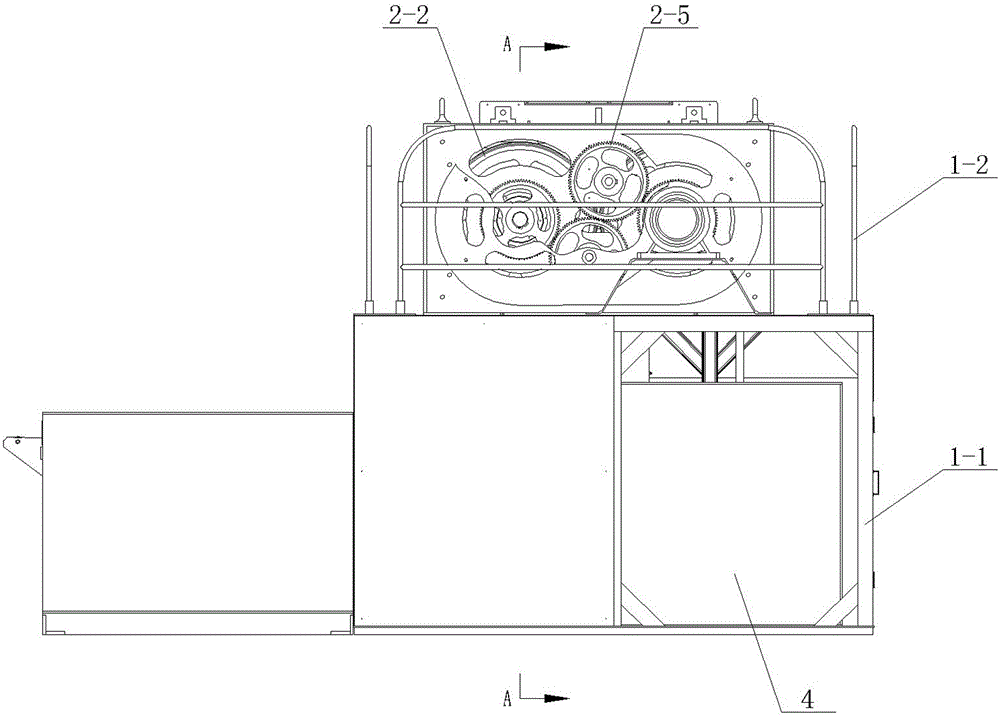

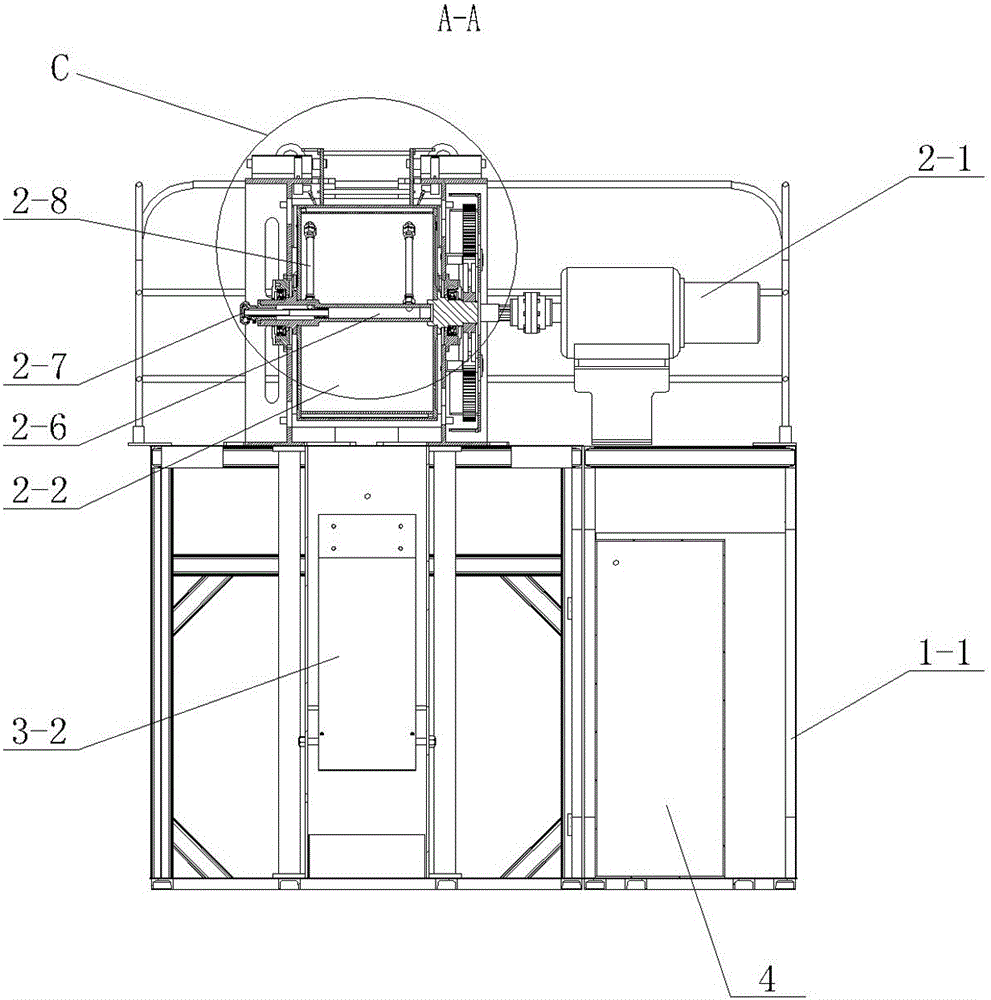

[0034] Such as figure 1 , figure 2 , Figure 5 , Figure 7 Shown is one of the embodiments of the present invention, in this embodiment, the main frame body 1 is provided with the roll-type lead belt forming machine, the main frame body 1 is the main supporting part of the lead belt forming machine, and the inside is provided with a section steel made The support 1-1 is provided with a switchable cabinet door on the side.

[0035] The upper part of the main frame body 1 is provided with a casting part 2 that casts lead liquid into a lead belt, and the main frame body 1 is provided with an output part 3 that accepts the formed lead belt, such as Figure 6 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com