Swing arm type eccentric lathing clamping structure

A clamping structure and eccentric technology, which is applied in the field of turbocharger shell lathe processing equipment, can solve the problems of workpiece clamping and turning difficulties, cumbersome and time-consuming clamping and fixing process, low work efficiency, etc., and achieve simple and convenient fixing process , Avoid use, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

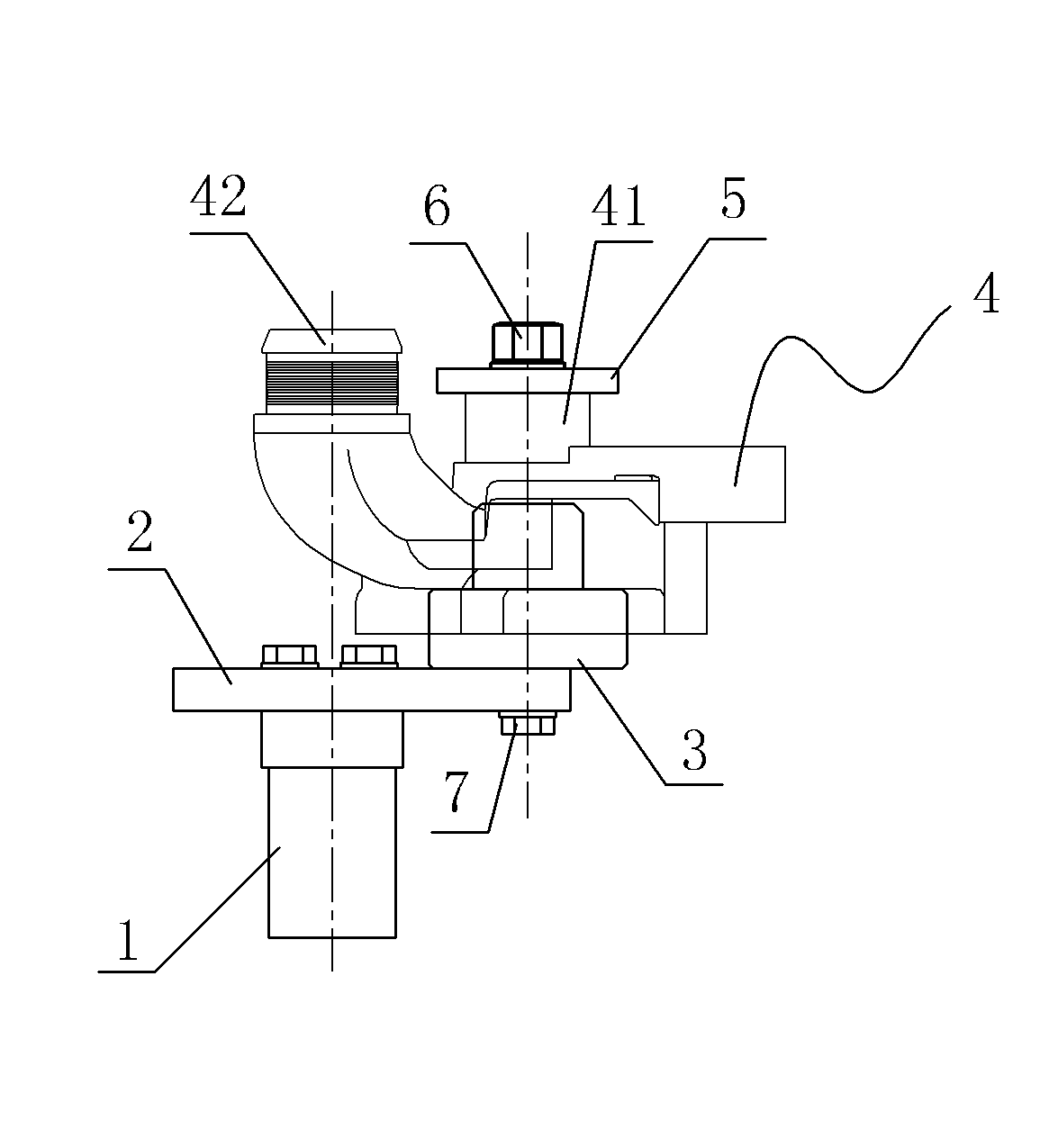

[0012] The swinging arm type eccentric car clamping structure includes claw clamping rod 1, long plate 2, positioning core 3, 4 is the pressure shell of the supercharger to be processed, and the claw clamping rod 1 is vertically fixed under one end of the long plate 2, and Fastened by bolts, the positioning core 3 is vertically fixed above the other end of the long plate 2 and fastened by bolts 7. The distance from the axis of the jaw clamp rod 1 to the axis of the positioning core 3 is the same as the center of the through hole 41 of the supercharger pressure shell to the outlet. The horizontal distance between the center of the end surface of the trachea 42 is equal, and the center of the positioning core 3 and the vertical direction of the long plate 2 have a screw hole that runs through the positioning core 3 and the long plate 2. 6. Connect and fix. The through hole 41 of the supercharger pressure casing is set on the positioning core 3, and is fastened by the pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com