Processable nickel-saving type austenitic stainless steel and production method thereof

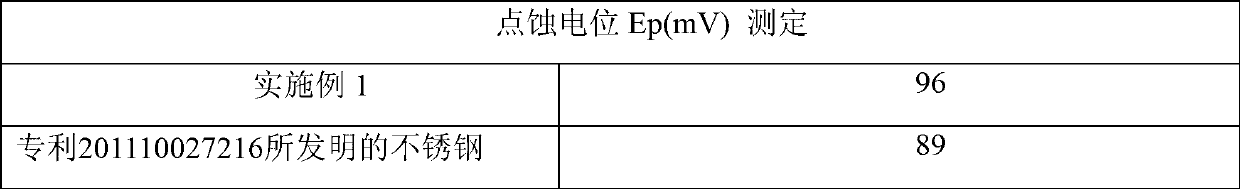

A technology of austenitic stainless steel and a manufacturing method, applied in the field of metal materials, can solve the problems of insufficient corrosion resistance and many surface defects, and achieve the effects of improving purity, reducing production costs and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

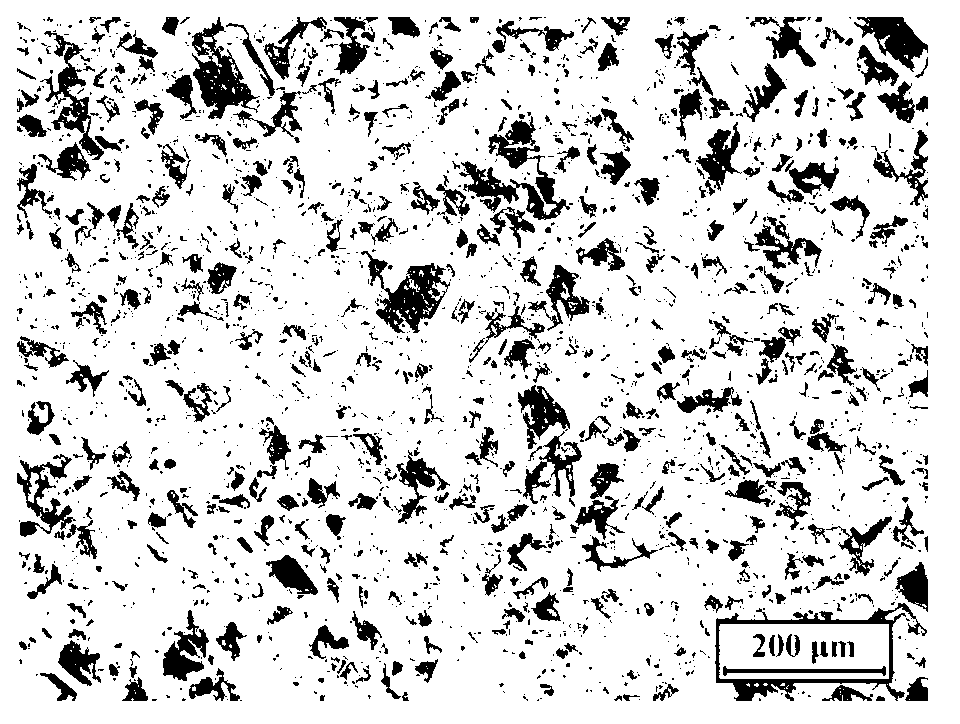

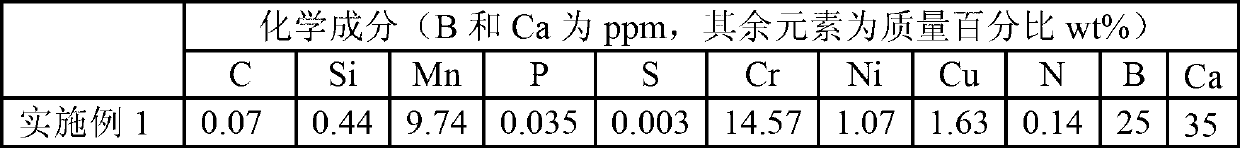

Embodiment 1

[0042] Using nickel-containing pig iron as the base material, its main chemical composition is: C 4.17%, S 0.16%, P 0.052%, Si 0.78%, Ni 1.68%, the balance is Fe, and high carbon is added at 242kg per ton of steel ferrochrome. Add it to the electric furnace to smelt the stainless steel mother liquor, the electric furnace smelting time is 105min, and the electric furnace tapping temperature is 1602°C; then the obtained stainless steel mother liquor is added to the GOR refining furnace, the quality of the manganese alloy added is 102kg / t steel, and the electrolytic copper is added The steel with a mass of 16.5kg / t is alloyed, the smelting time is 102min, and the tapping temperature is 1552°C. Alloyed molten steel is obtained, its chemical composition is by mass percentage: C 0.07%, Si 0.44%, Mn 9.74%, S 0.003%, P 0.035%, Ni 1.07%, Cr 14.57%, Cu 1.63%, N 0.14%, The balance is Fe.

[0043] The molten steel is then sent to LF for treatment, and the temperature of the molten steel...

Embodiment 2

[0057] Using nickel-containing pig iron as the base material, its main chemical composition is: C 4.27%, S 0.13%, P 0.051%, Si 0.85%, Ni 1.63%, the balance is Fe, and high carbon is added at 281kg per ton of steel ferrochrome. Add it to the electric furnace to smelt the stainless steel mother liquor. The electric furnace smelting time is 119min, and the electric furnace tapping temperature is 1610°C; then the obtained stainless steel mother liquor is added to the GOR refining furnace. The quality of copper is 17.9kg / t steel alloying smelting time is 99min, and the tapping temperature is 1548℃. Alloyed molten steel is obtained, and its chemical composition is by mass percentage: C0.065%, Si 0.43%, Mn 9.46%, S 0.003%, P 0.037%, Ni 0.79%, Cr 16.78%, Cu 1.78%, N 0.15% , the balance being Fe.

[0058] The molten steel is then sent to LF for treatment, and the temperature of the molten steel is raised to 1538°C by electric heating through the LF furnace. After micro-alloying of f...

Embodiment 3

[0072] Using nickel-containing pig iron as the base material, its main chemical composition is: C 4.5%, S 0.15%, P 0.049%, Si 0.80%, Ni 1.69%, and the balance is Fe. Carbon ferrochrome. Add it to the electric furnace to smelt the stainless steel mother liquor. The electric furnace smelting time is 99min, and the electric furnace tapping temperature is 1605°C; then the obtained stainless steel mother liquor is added to the GOR refining furnace, and at the same time, the quality of the manganese alloy is added to 122kg / t steel, and the electrolytic copper is added. The quality of the steel is 21.2kg / t for alloying, the smelting time is 102min, and the tapping temperature is 1550℃. Alloyed molten steel is obtained, its chemical composition is by mass percentage: C0.085%, Si 0.47%, Mn 11.86%, S 0.003%, P 0.034%, Ni 2.32%, Cr 15.69%, Cu 2.10%, N 0.13% , the balance being Fe.

[0073] The molten steel is then sent to LF for treatment, and the molten steel is heated up to 1540°C by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap