Shuttle rebounding connection rod

A technology of connecting rod and shuttle, applied in textile, textile and papermaking, looms and other directions, can solve the problems of insufficient avoidance of other parts, large rotation space, unfavorable internal structure assembly of projectile looms, etc., to achieve convenient assembly, Assemble the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described below with reference to the drawings.

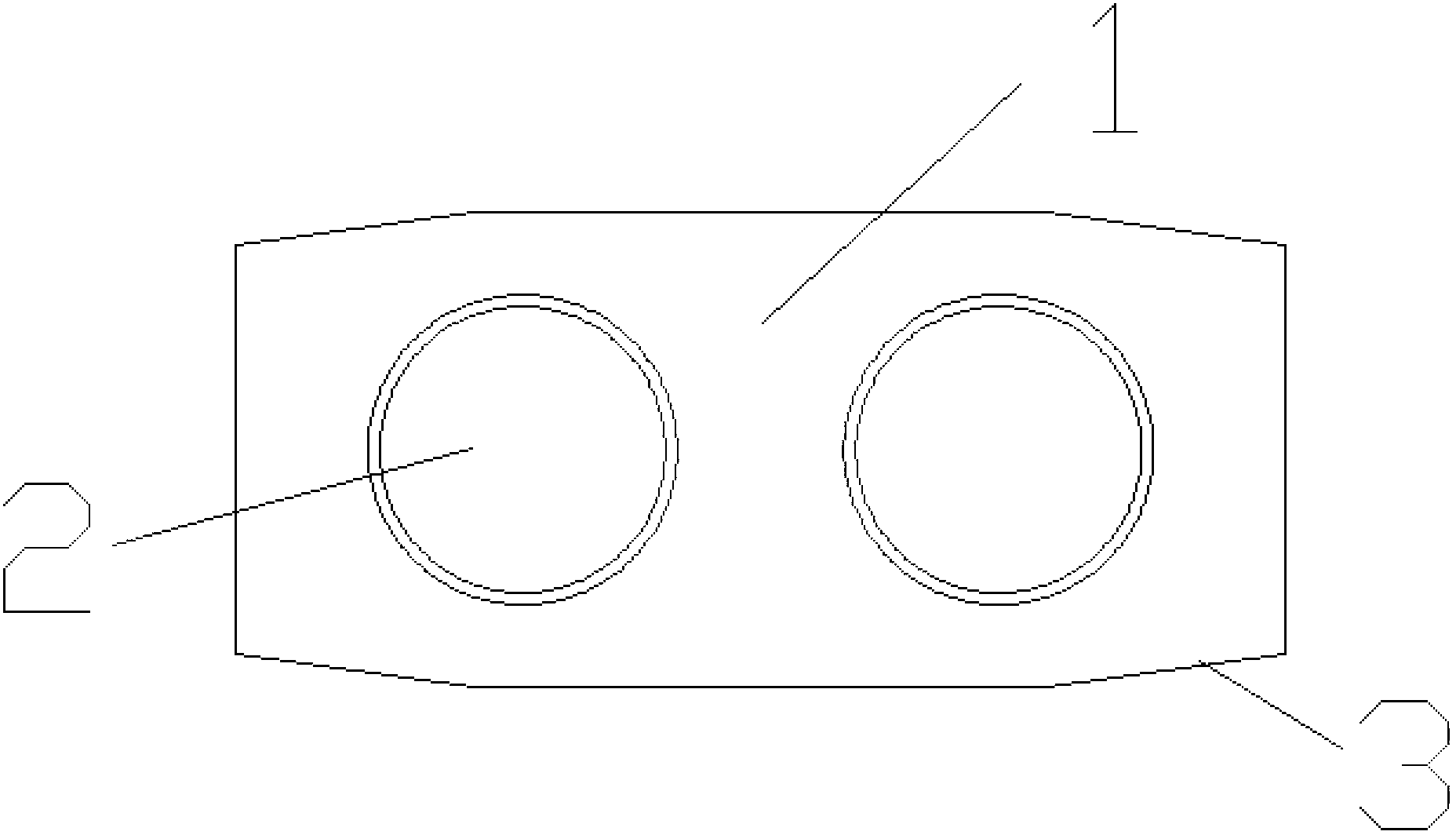

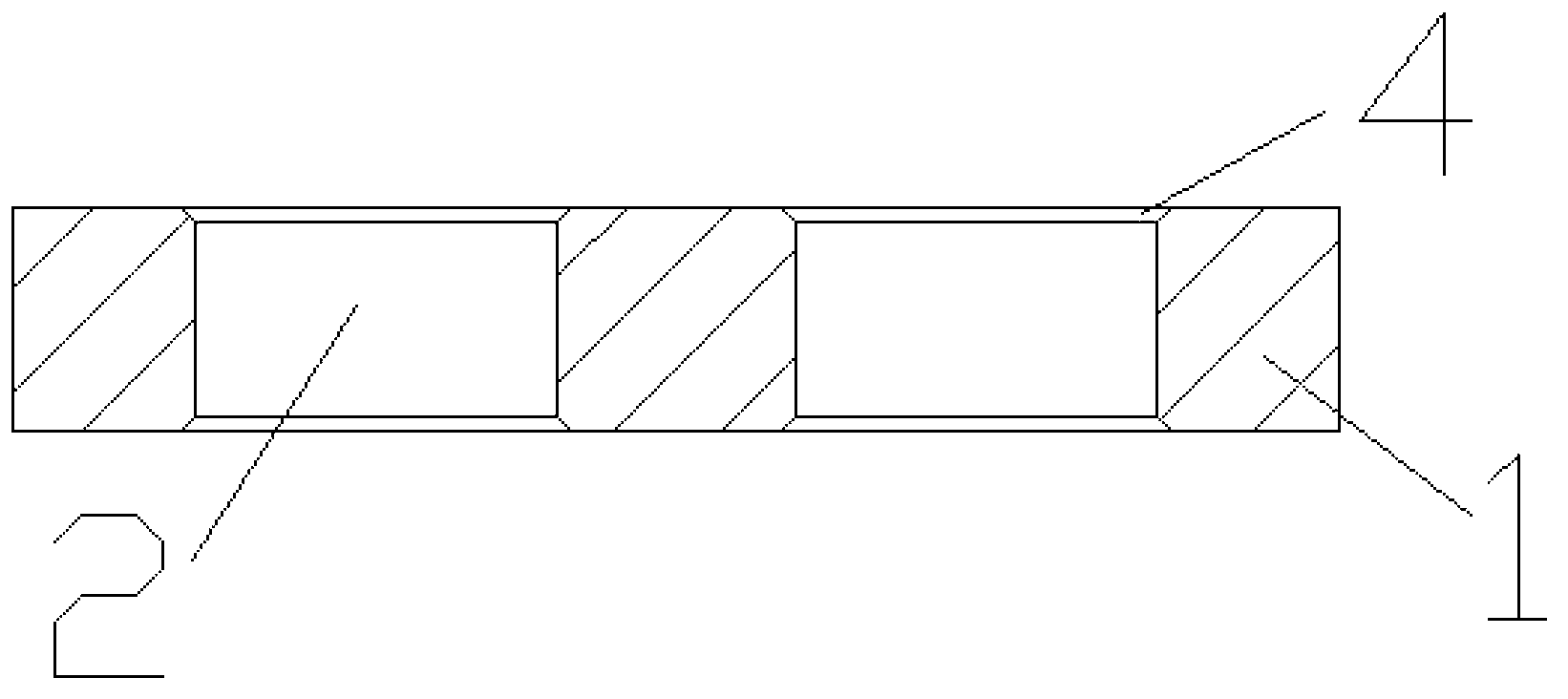

[0014] As attached figure 1 , 2 The shuttle link of the present invention includes a shuttle link body 1, which is arranged in a rectangular block structure; the shuttle link body 1 is symmetrical in the length direction Two circular through holes 2 are opened; the four top corners of the shuttle link body 1 are respectively provided with first chamfers 3. The four top corners of the shuttle connecting rod body 1 have the same first chamfer 3 arc. The upper and lower openings of the circular through hole 2 are respectively provided with second chamfers 4 with the same arc.

[0015] The shuttle connecting rod of the present invention has a small rotating space during use, which can avoid other parts and make the assembly structure of the projectile loom compact; at the same time, the upper, The lower orifices are respectively provided with second chamfers 4 with the same arc, which facilitates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com