Axial-flow air inlet mechanism for two-stroke engine

An air intake mechanism, engine technology, used in combustion engines, machines/engines, internal combustion piston engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

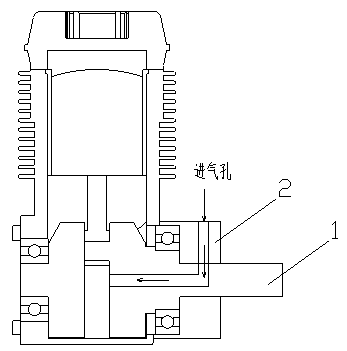

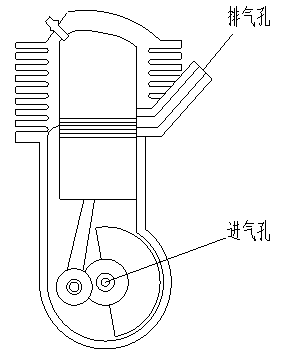

[0015] Such as figure 1 , figure 2 As shown, the axial flow intake mechanism of the two-stroke engine of the present invention includes a crankshaft 1 and a bushing 2, and there is relative movement between the crankshaft 1 and the bushing 2;

[0016] A through hole is opened on the shaft sleeve 2;

[0017] The crankshaft 1 is a hollow shaft; a connecting hole is opened on the position of the crankshaft 1 matching the through hole of the bushing 2, and the connecting hole connects the through hole of the bushing 2 with the hollow part of the crankshaft to form an axial flow valve intake channel ;

[0018] The through hole on the shaft sleeve 2 is externally connected to the carburetor.

[0019] The working principle of the present invention is as follows:

[0020] Crankshaft 1 rotates, and when the connecting hole on the crankshaft 1 communicates with the through hole on the axle sleeve 2, it starts to charge the oil-gas mixture to prepare for the next work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com