Multiple-step shaft end face run-out detecting gauge

A beating detection, multi-step technology, applied in measuring devices, instruments, etc., can solve the problems of inconsistent detection accuracy, low efficiency, affecting detection and processing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

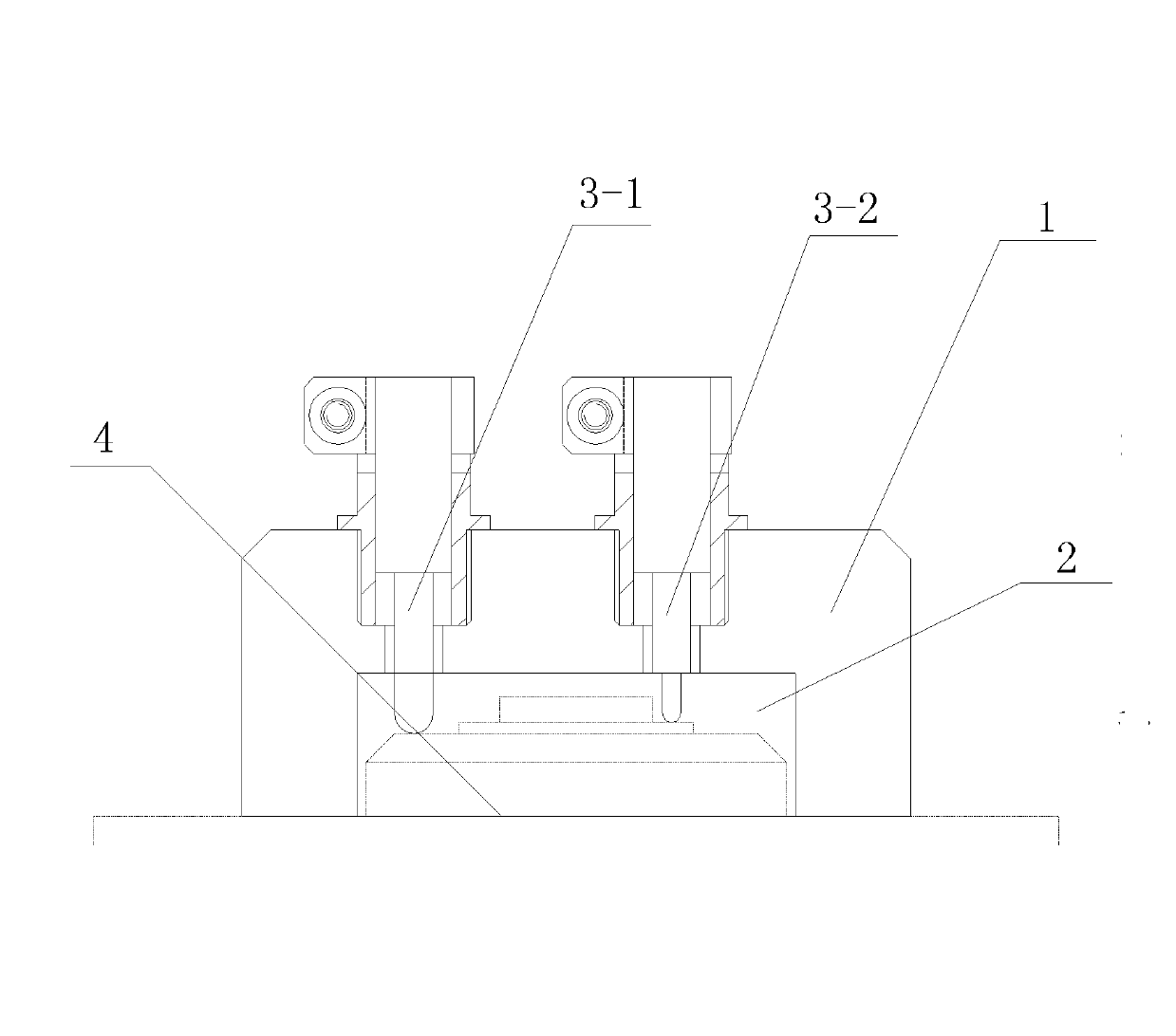

[0008] See figure 1 , a multi-step shaft end surface runout detection gauge, which includes a detection module 1, a detection cavity 2 corresponding to a multi-step shaft 4 is arranged in the detection module 1, and a detection cavity 2 corresponding to the detection module 1 is provided with a step end surface respectively The corresponding two detection heads 3-1 and 3-2 respectively detect the end face of each step at the same time through the detection head, which effectively avoids the deviation of detection, ensures the detection and processing quality of the multi-step shaft end face, and improves the detection efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com