Radar level gauge

A technology of radar level gauge and waveguide head, which is applied in liquid/fluid solid measurement, engine lubrication, instruments, etc. It can solve the problems of no pressure resistance, poor sealing effect of electronic components, affecting stability, etc., and achieve improved sealing Performance, guaranteed sealing effect, effect of radiation resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will further illustrate the present invention in conjunction with embodiments:

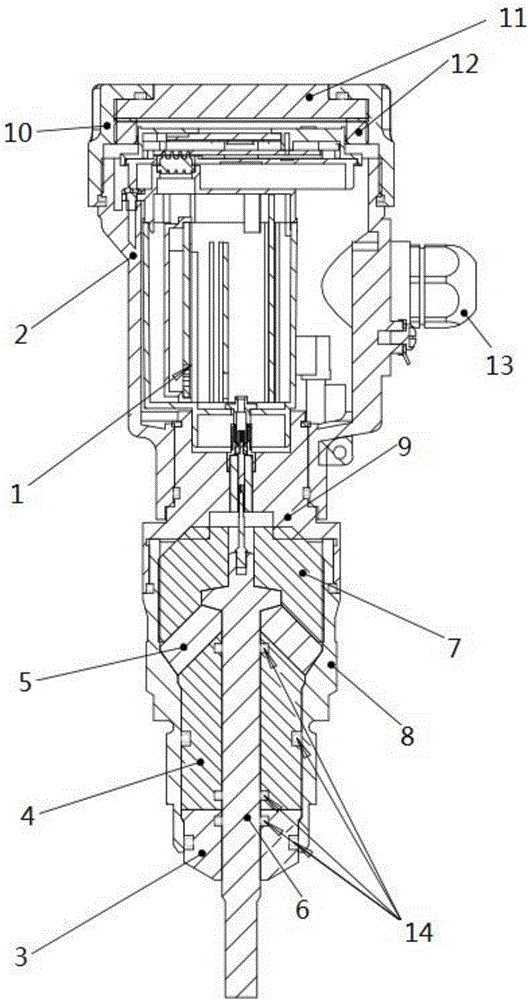

[0018] Figure 1-2 Shows the schematic structural diagram and cross-sectional view of the radar level gauge of the present invention.

[0019] Such as Figure 1-2 As shown, it includes electronic components 1, housing base 2, lower cover 3, upper sleeve 4, support 5, guide wave head inner rod 6, sealing rubber 7, guide wave head housing 8, guide wave head top cover 9, and housing upper The cover 10, the transparent window 11, the transparent window pressing ring 12, the cable gland 13 and the O sealing ring 14, wherein the transparent window 11 is set on the housing upper cover 10 through the transparent window pressing ring 12, the housing upper cover 10 and the housing One end of the base 2 is connected, a cavity is formed inside the housing base 2, and the electronic component 1 is arranged in the cavity inside the housing base 2. One end of the wave guide top cover 9 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com