Bus shearing machine

A technology for shearing machines and busbars, which is applied in the direction of shearing devices, shearing machine equipment, and knives for shearing machine devices, can solve the problems of complex and heavy structures and inconvenient operations, and achieve convenient operation, simple and light structure Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

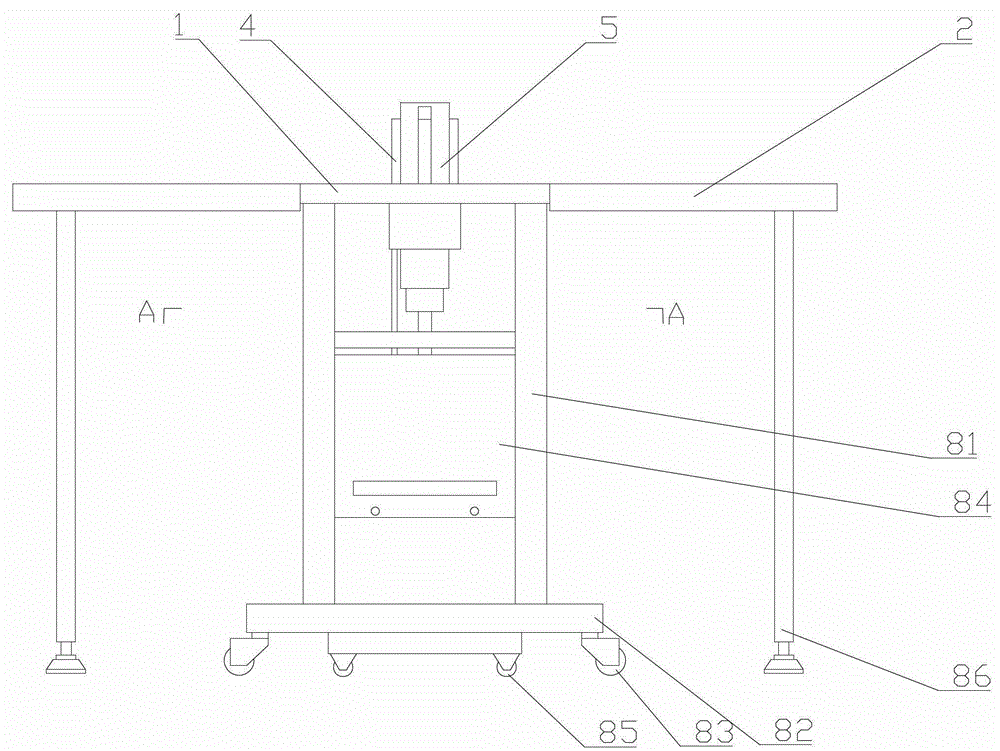

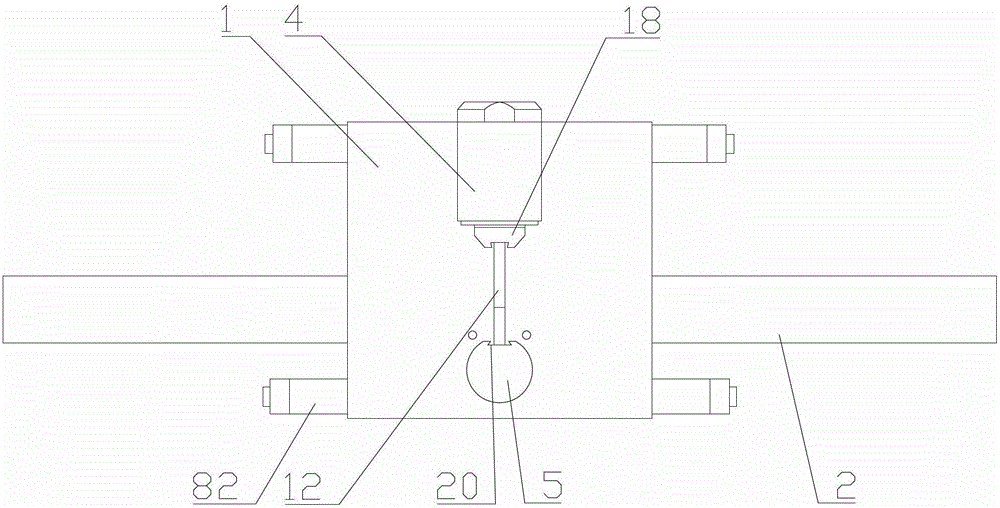

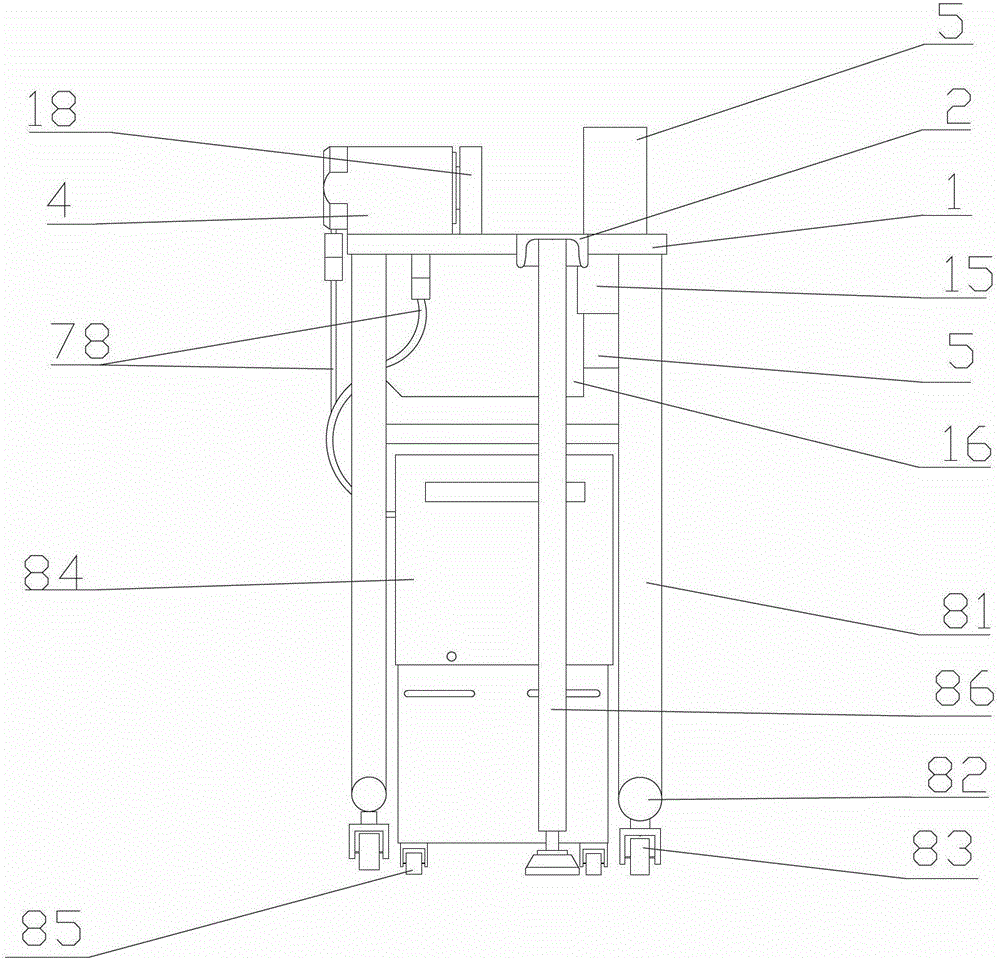

[0028] like Figures 11 to 14 As shown: it includes a platen 1, a support plate 2, an oil cylinder 4 connected with a power device, a pressure head 18, a column 5, and a shearing mold. The platen is used for loading or connecting related components, and longitudinal Arranged oil cylinder sockets 11, guide grooves 12, and column fixing holes 13, the oil cylinder is inserted into the oil cylinder socket through the oil cylinder foot 14 provided on the lower wall of the oil cylinder, the oil cylinder is fixed on the platen by bolts, and the column passes through the column The fixing hole 13 is set on the reinforcing sleeve 15 provided under the fixing hole of the column; the reinforcing sleeve plays the role of strengthening the fixing of the column, and the lower wall of the platen is connected with a reinforcing plate perpendicular to the platen from the rear end of the oil cylinder to the direction of the column 16. The reinforcing plate is connected with the column and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com