Overturn driving device for post inflation of tire vulcanizer

A driving device and tire vulcanization technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of reducing the service life of equipment, deformation of crossbeam stoppers, damage to reducers, etc., to achieve short action time, reduce impact and Vibration and flipping are highly reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the drawings and embodiments.

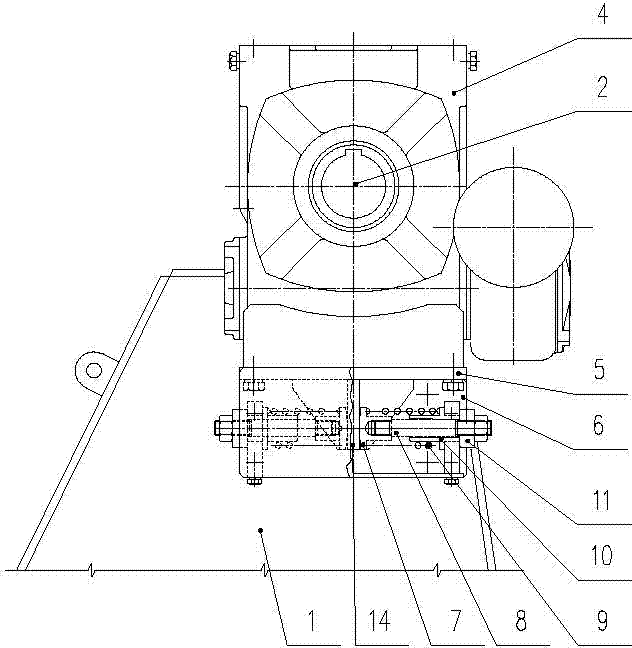

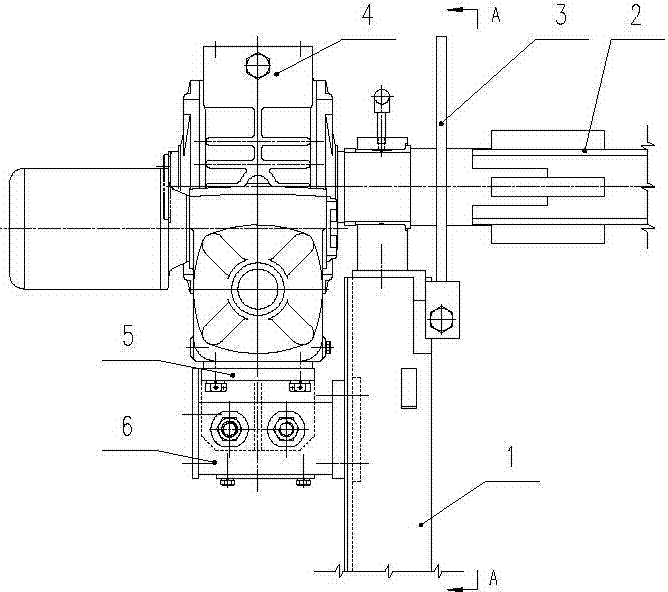

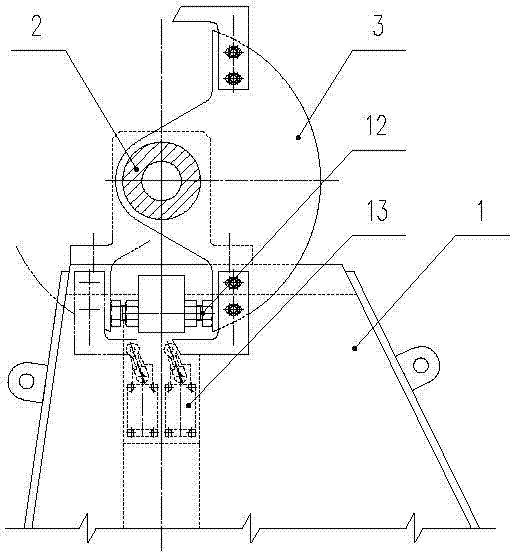

[0012] by figure 1 , figure 2 , image 3 It can be seen that a turning drive device for rear inflation of a tire vulcanizer includes a rear inflation frame 1, a rear inflation cross beam 2 is installed on the rear inflation frame 1, and can be rotated in the sleeve of the rear inflation frame 1, and the rear inflation cross beam 2 The shaft and the output shaft of the reducer 4 with motor are connected by a key. The rear inflatable frame 1 is connected with a support frame 6, and the two ends of the support frame 6 are respectively provided with a buffer mechanism, and the reducer 4 with a motor is provided with a bracket 5 , The bracket 5 is provided with a pressure plate 14 connected with the buffer mechanism.

[0013] In order to ensure the buffering effect, the buffering mechanism of the present invention is divided into two groups.

[0014] The buffer mechanism of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com