Push-type elastic balloon pump

An elastic bag and push-type technology, which is applied in the direction of closing, packaging, and dispensing devices, can solve the problems of low utilization rate and low efficiency of the pump stroke, and achieve the effects of beautifying life, improving volumetric efficiency, and large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

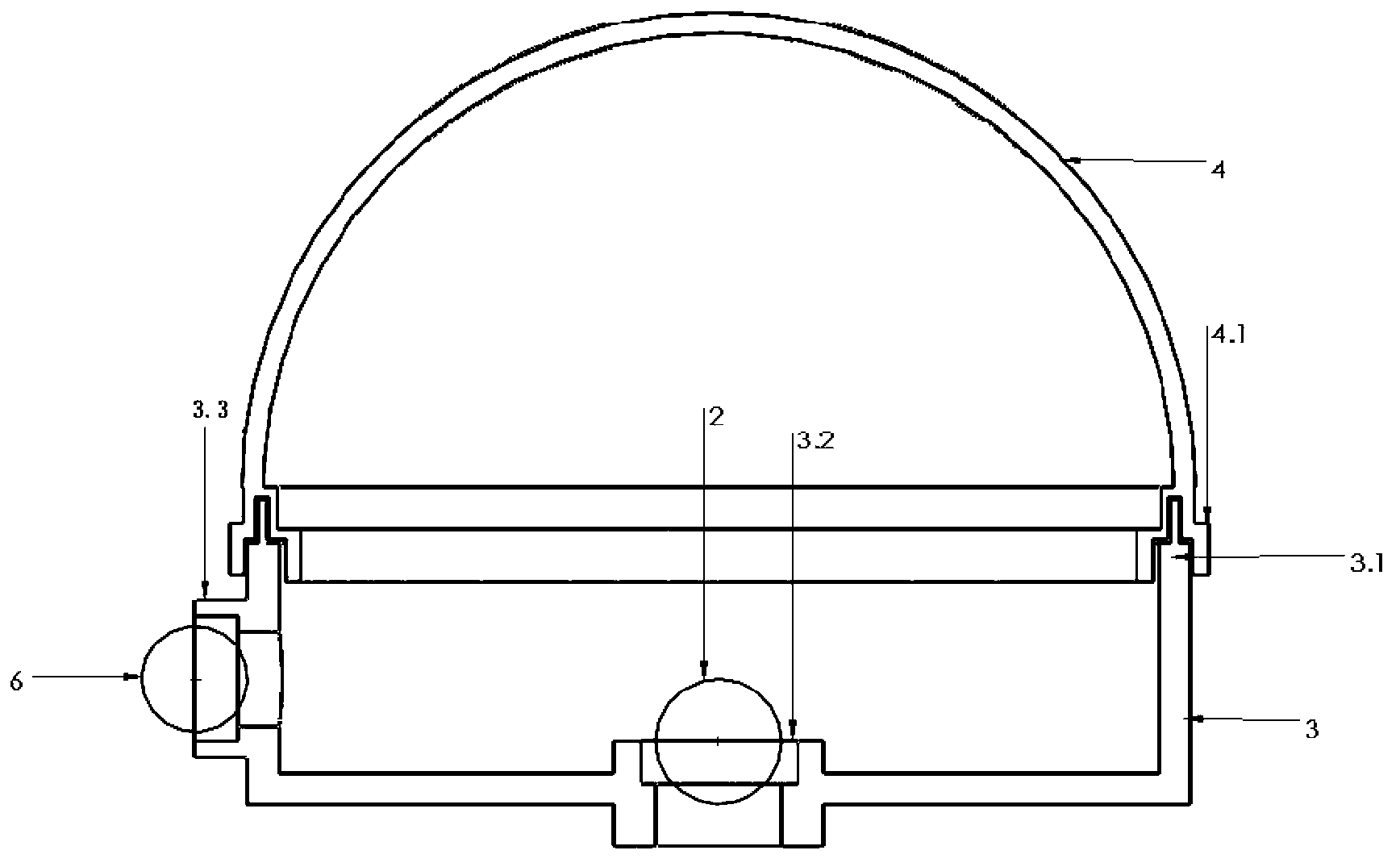

[0043] like figure 1 As shown, the push-type elastic bag pump includes a pump body 3 and an elastic bag 4 . The center of the pump body 3 has an inlet port 3.2, which is the inlet channel of the pump, and an inlet check valve 2 is installed in it; the side wall 3.3 of the pump body 3 has an outlet port 3.3, which is the outlet channel of the pump, and an outlet is installed in the outlet port 3.3. One-way valve 6; pump body 3 upper opening has junction 3.1, and elastic capsule 4 has outer edge 4.1 that can cooperate with the junction 3.1 of caulking into pump body 3, and forms sealing, has just constituted push-type elastic capsule pump.

Embodiment 2

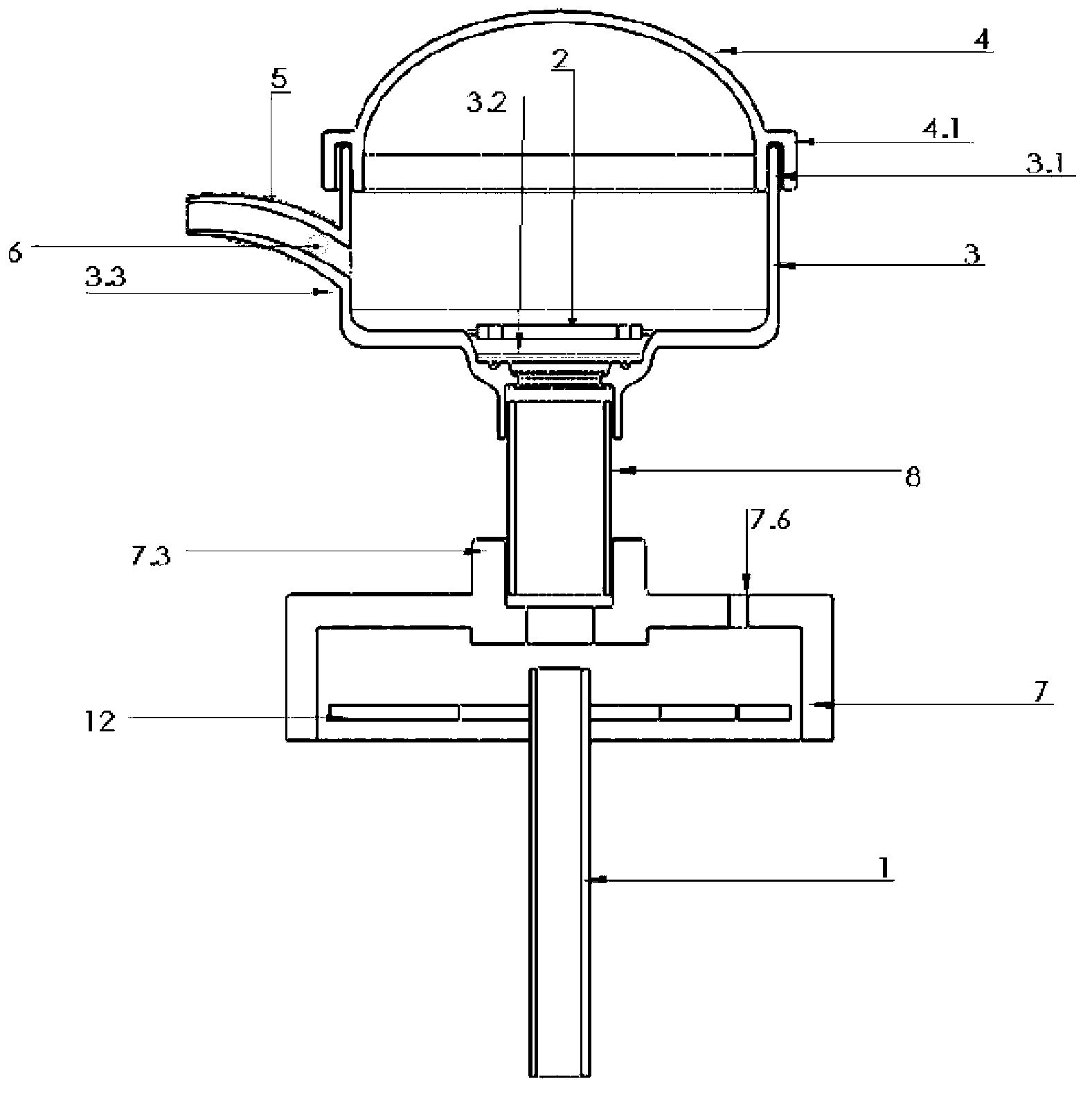

[0045] This embodiment is a specific application structure based on the first embodiment, such as figure 2As shown, the positional relationship between the push-type elastic bag pump, the pressure rod 8 and the bottle cap 7 is the same as that of the conventional piston pump, and the push-type elastic bag pump replaces the nozzle. The lower end of the inlet port 3.2 of the pump body 3 is connected with the pressure rod 8, and the other end of the pressure rod 8 is connected with the bottle cap 7 interface 7.3 and then connected with the guide tube 1, which is located in the bottle cap 7 and extends into the bottle; the nozzle 5 of the spray head and The outlet port 3.3 of the pump body 3 is integrated, the elastic bag 4 becomes the pressing surface, and the liquid can flow out from the nozzle 5, which is completely the same as the nozzle. The ring gap in the bottle cap 7 has a sealing ring 12, and the ring gap has a balance aperture 7.6, such as Figure 10 Shown, seal ring 1...

Embodiment 3

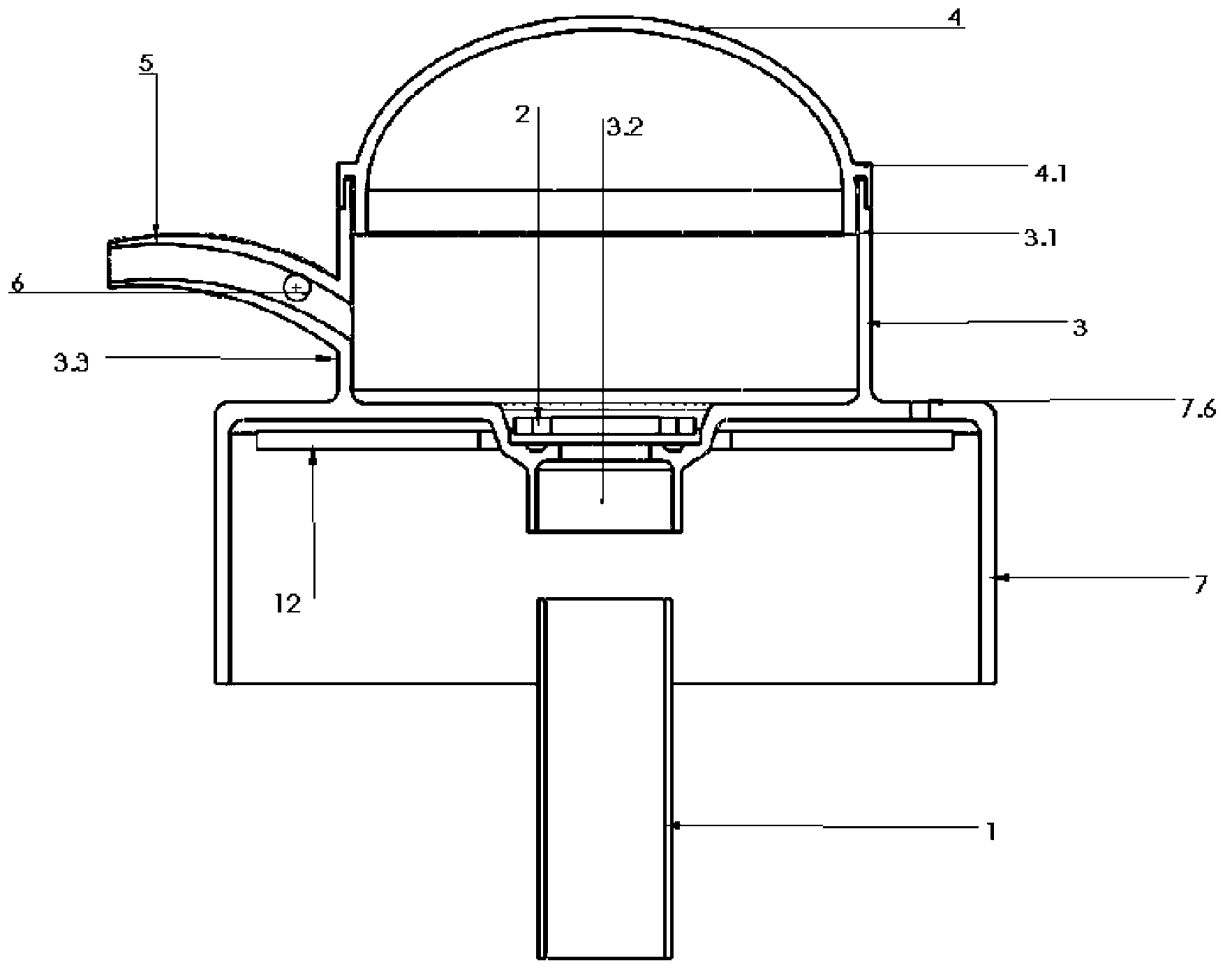

[0048] This embodiment is a specific application structure based on the first embodiment, such as image 3 As shown, the push-type elastic bag pump is configured on the bottle cap 7 . The bottom of the pump body 3 is a part of the bottle cap 7, that is, the bottom of the pump body 3 is integrated with the bottle cap 7, the inlet port 3.2 in the center of the pump body 3 is in the center of the bottle cap 7, and the lower end of the inlet port 3.2 is connected to the guide tube 1 , the guide tube 1 is located in the bottle cap 7 and extends into the bottle; the nozzle 5 and the outlet port 3.3 of the pump body 3 are integrated; There are balance holes 7.6, such as Figure 10 Shown, seal ring 12 adds knife edge, just forms one-way hinge 12.1, and the one-way hinge 12.1 of seal ring 12 is right against balance aperture 7.6 center.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com