Long-life extension-resistant threaded mesh belt

A technology of anti-extrusion and longevity, applied in the field of mechanical conveying devices, can solve problems such as broken mesh belts, short service life, and insufficient solder joints, and achieve the effect of firm structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

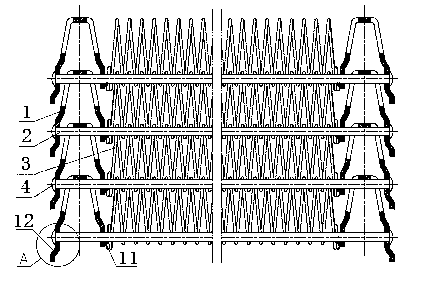

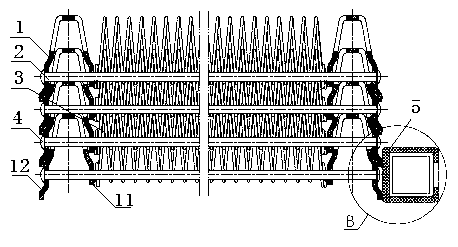

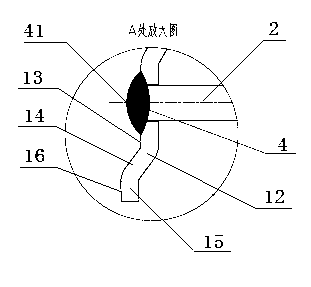

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] figure 1 2 is the principle of the maximum stretch state of the spiral mesh belt, 2 is the principle diagram of the minimum contraction state of the spiral mesh belt, image 3 for figure 1 Enlarged view of A, Figure 4 for figure 2 The enlarged view of B in the figure, as shown in the figure, the present invention includes that the string rod (2) is sequentially connected with the connecting plate (1), the threaded line (3) and the connecting plate (1) on the other side in sequence, and is characterized in that: The two ends of the string rod (2) are made with arc risers (4), and the arc riser (4) is fixedly connected with the string rod (2) and the connecting plate (1), and the top of the riser (41) reaches The distance from the outer end surface (13) is smaller than the distance from the outer end protruding surface (16) to the outer end surface (13); the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com