Method for controlling ore melting of electric heating furnace by utilizing parametric modeling

A technology of parametric modeling and electric heating furnace, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of failure to meet the requirements, the process of high temperature radiation and phase change in porous media is extremely complex, and lacks theoretical basis and other issues to achieve the effect of reducing the difficulty of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The hardware environment that the present invention is used for implementing is quad-core cpu 2.7G computer, 4G memory, 512 graphics cards, the environment of operation is ANSYS12.0, Microsoft Visual Basic 6.0 and Windows XP64 bit system; ANSYS software is fusion structure, fluid, electric field, Magnetic field, sound field analysis and integrated large-scale general-purpose finite element analysis software, ANSYS Parametric Design Language (APDL parametric design language) programming environment.

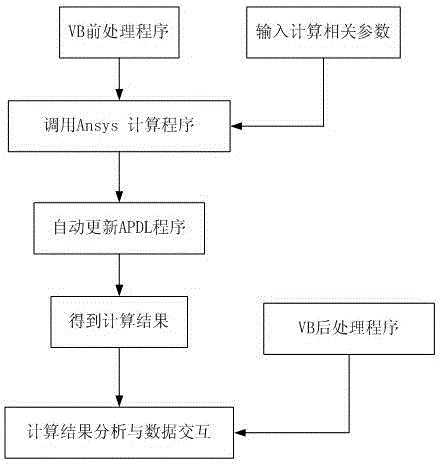

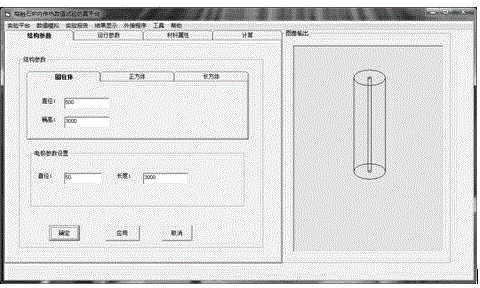

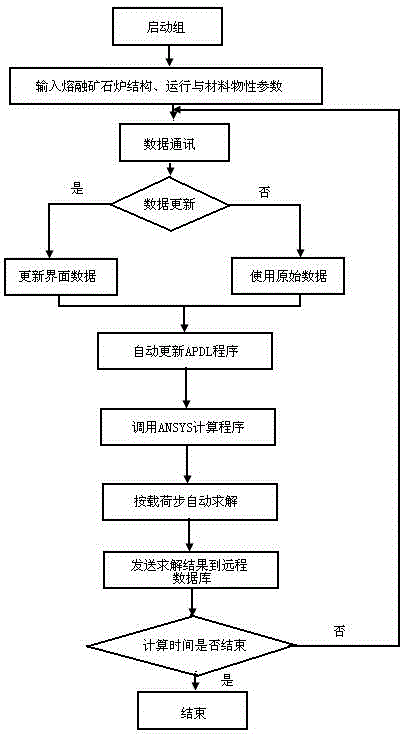

[0035] figure 1 It is a schematic diagram of the program structure of the present invention. Because VB adopts event programming, the system framework design of the program is particularly important; the program system mainly consists of three parts: user interface pre-processing, calling ANSYS analysis calculation and remote interaction, and result post-processing; The interface pre-processing program realizes the interaction between the system and the user, completes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com