Catalyst-supporting substrate, method of manufacturing the same, membrane electrode assembly, and fuel cell

A manufacturing method and catalyst technology, applied in the direction of solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as insufficient durability, and achieve the effect of high durability and high-quality activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] (Preparation of Catalyst Supporting Substrates in Examples 1-21)

[0067] According to the conditions described in Table 1 below, the catalyst-carrying substrates of Examples 1 to 21 were prepared. Specifically, it was manufactured as follows.

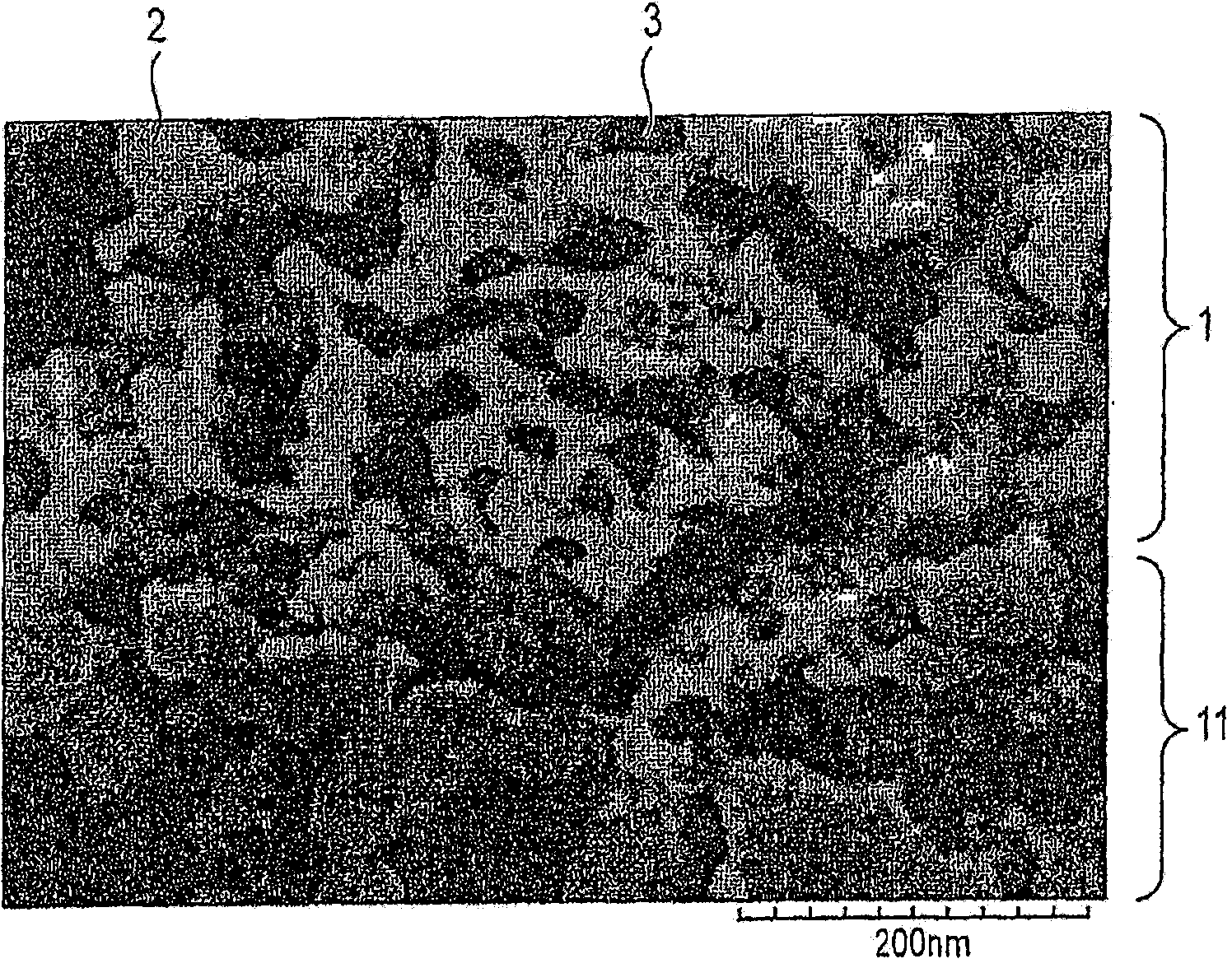

[0068] As a substrate, carbon paper (manufactured by Toray Corporation, trade name: Toray 060) was prepared. The substrate has a carbon layer with a thickness of 5-50 μm on its surface. To this substrate, in each example, the first material having the composition shown in Table 1 was sputtered. Furthermore, as described above, in each example, the second material having the composition shown in Table 1 was sputtered. The sputtering of the first material and the sputtering of the second material were repeated until the supported amount and the thickness of the catalyst layer shown in Table 1 were obtained in each Example. To be explained, 0.2mg / cm 2 The Pt loading corresponds to an average Pt thickness of about 100 nm. Thus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com