Graphene-polypyrrole/platinum nano modified glassy carbon electrode, preparation method for same and application thereof

A glassy carbon electrode and graphene technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as catalyst poisoning and deactivation, DMFC efficiency decline, etc., and achieve high current density, large mass activity, and strong anti-toxicity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039](1) Polishing of the glassy carbon electrode: the glassy carbon electrode is polished to a mirror surface with aluminum oxide suspensions with a particle size of 0.3 μm and 0.05 μm, and then the glassy carbon electrode is polished to a mirror surface with 99% ethanol by volume fraction, twice Ultrasonic cleaning with distilled water to obtain a polished glassy carbon electrode 1;

[0040] (2) Preparation of graphene-modified glassy carbon electrode: blow dry the glassy carbon electrode 1 treated in step (1) with high-purity nitrogen, and evenly coat the surface with a graphene solution with a volume and concentration of 5 μl and a concentration of 1 mg / ml. Bake under an infrared lamp until no liquid remains to obtain a graphene-modified glassy carbon electrode 2;

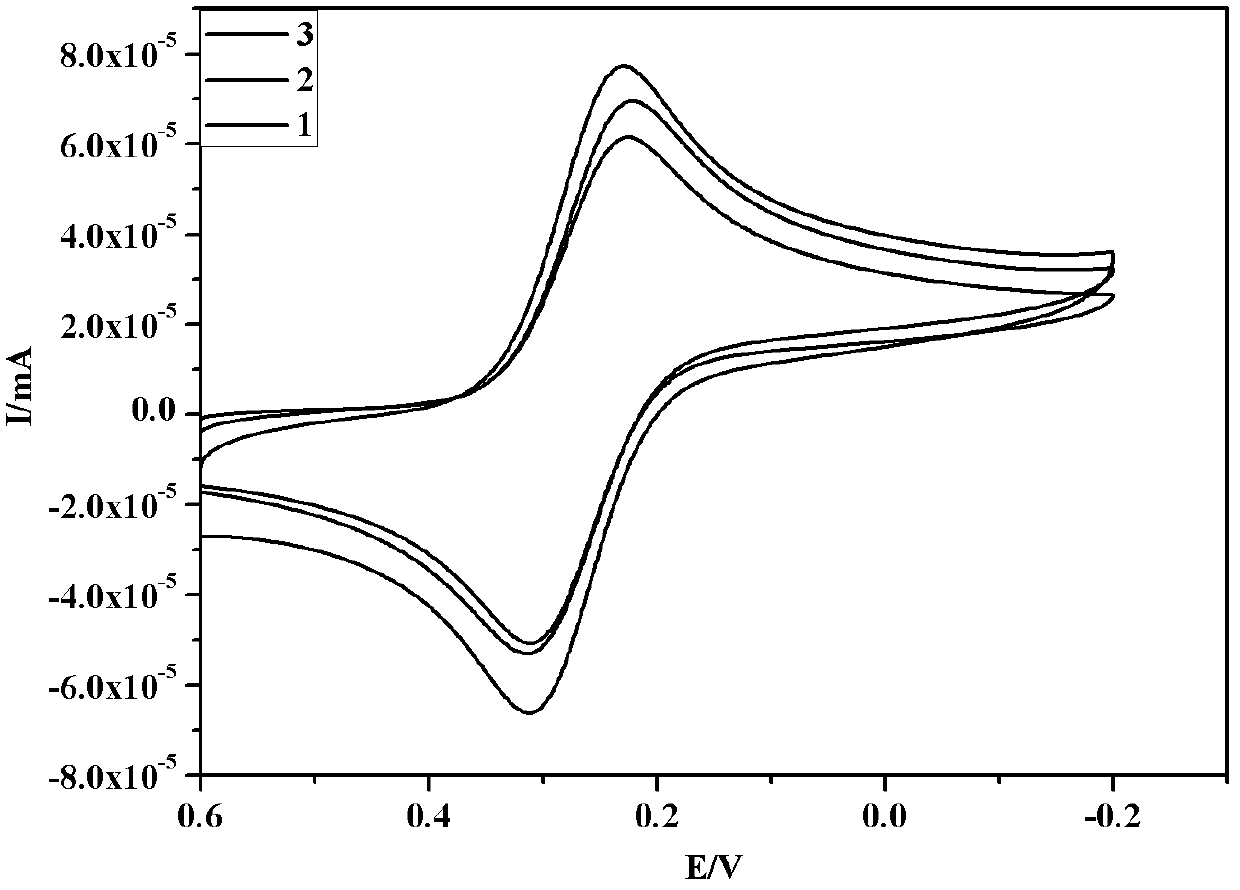

[0041] (3) Preparation of graphene-polypyrrole-modified glassy carbon electrode: place the graphene-modified glassy carbon electrode 2 obtained in step (2) in pyrrole, NaHCO 3 and LiClO 4 In the electrolyte ...

Embodiment 2

[0049] (1) The polishing of the glassy carbon electrode is the same as in Example 1;

[0050] (2) The preparation of the graphene-modified glassy carbon electrode is the same as in Example 1;

[0051] (3) Preparation of graphene-polypyrrole-modified glassy carbon electrode: the graphene-modified glassy carbon electrode 2 obtained in step (2) was placed in a 3 and LiClO 4 In the electrolyte solution, pyrrole was electrodeposited at a constant potential of 0.6V for 20s to obtain a graphene-polypyrrole modified glassy carbon electrode 3;

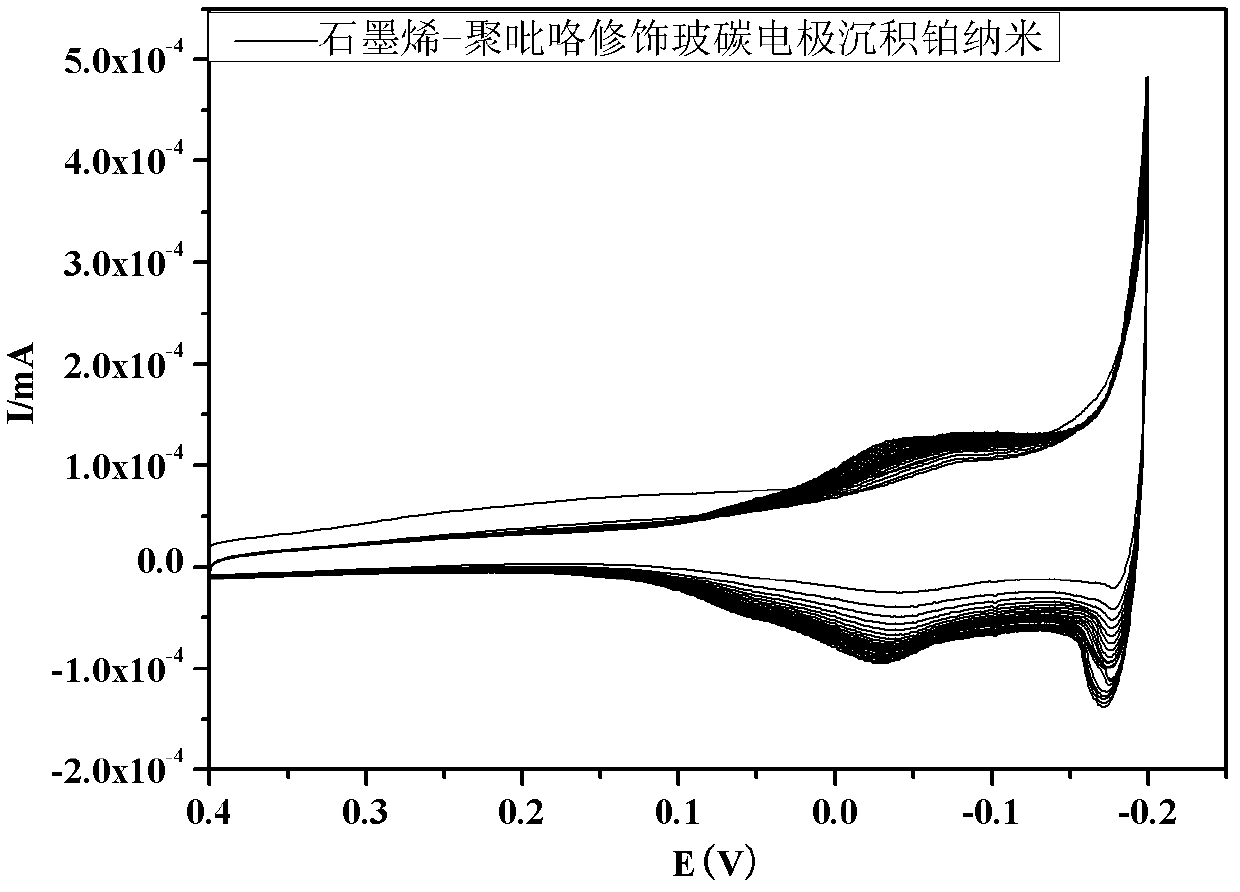

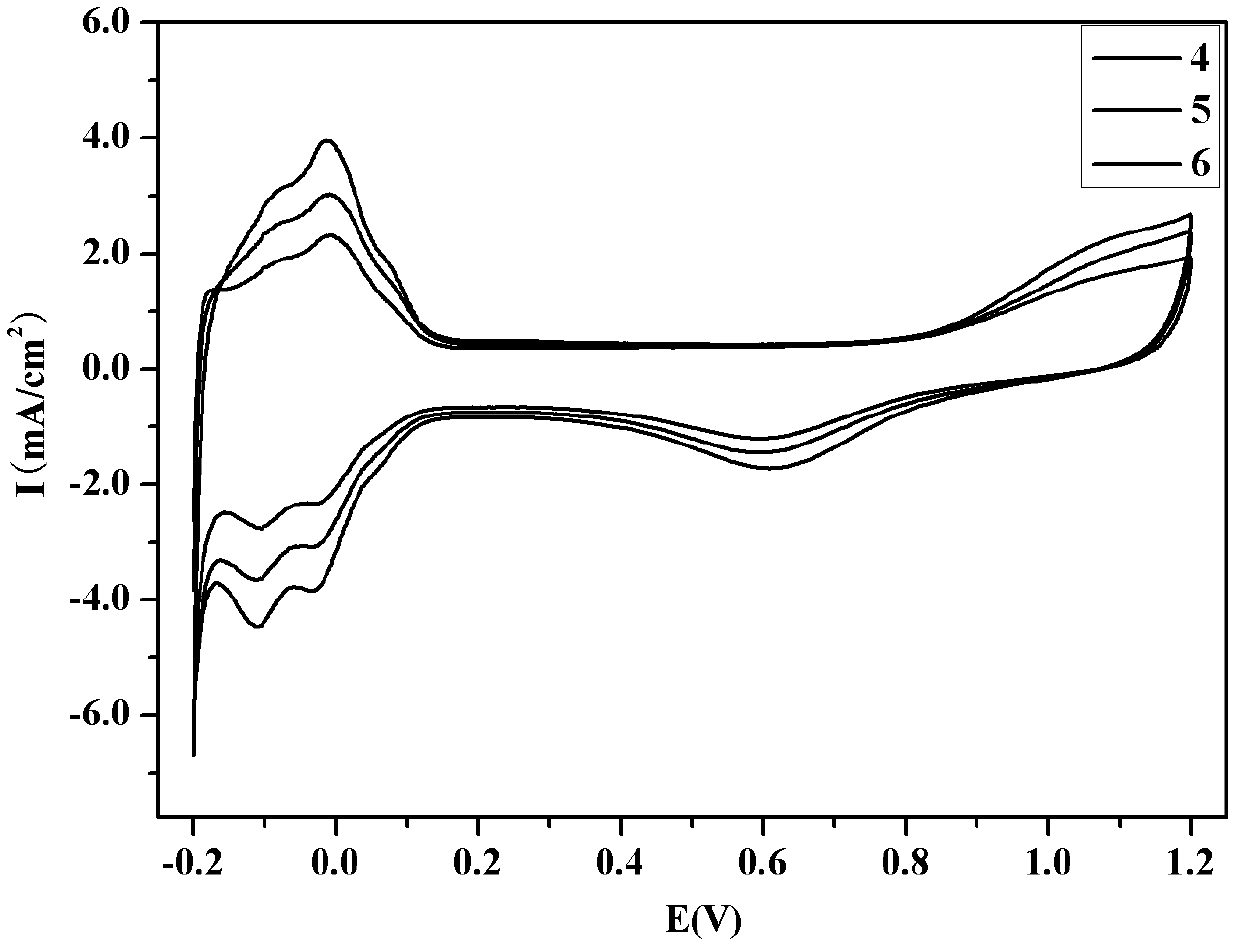

[0052] (4) Preparation of graphene-polypyrrole / platinum nano-modified glassy carbon electrode: Rinse the graphene-polypyrrole-modified glassy carbon electrode 3 obtained in step (3) with double distilled water, and 2 SO 4 and H 2 PtCl 6 In the electrolyte solution, the graphene-polypyrrole modified glassy carbon electrode 3 is used as the working electrode, Ag / AgCl is used as the reference electrode, and platinum wire is used as the counte...

Embodiment 3

[0055] (1) The polishing of the glassy carbon electrode is the same as in Example 1;

[0056] (2) The preparation of the graphene-modified glassy carbon electrode is the same as in Example 1;

[0057] (3) Preparation of graphene-polypyrrole-modified glassy carbon electrode: the graphene-modified glassy carbon electrode 2 obtained in step (2) was placed in a 3 and LiClO 4 In the electrolyte solution, pyrrole was electrodeposited at a constant potential of 0.7V for 30s to obtain a graphene-polypyrrole modified glassy carbon electrode 3;

[0058] (4) Preparation of graphene-polypyrrole / platinum nano-modified glassy carbon electrode: Rinse the graphene-polypyrrole-modified glassy carbon electrode 3 obtained in step (3) with double distilled water, and 2 SO 4 and H 2 PtCl 6 In the electrolyte, the graphene-polypyrrole modified glassy carbon electrode 3 is used as the working electrode, Ag / AgCl is used as the reference electrode, and platinum (Pt) wire is used as the counter el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com