Nano-catalyst for electrochemical preparation of hydrogen peroxide, and preparation method and application thereof

A nano-catalyst, hydrogen peroxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., can solve high overpotential, limited catalytic activity, adsorption capacity Poor problems, to achieve the effect of increased selectivity and activity, high-quality activity, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

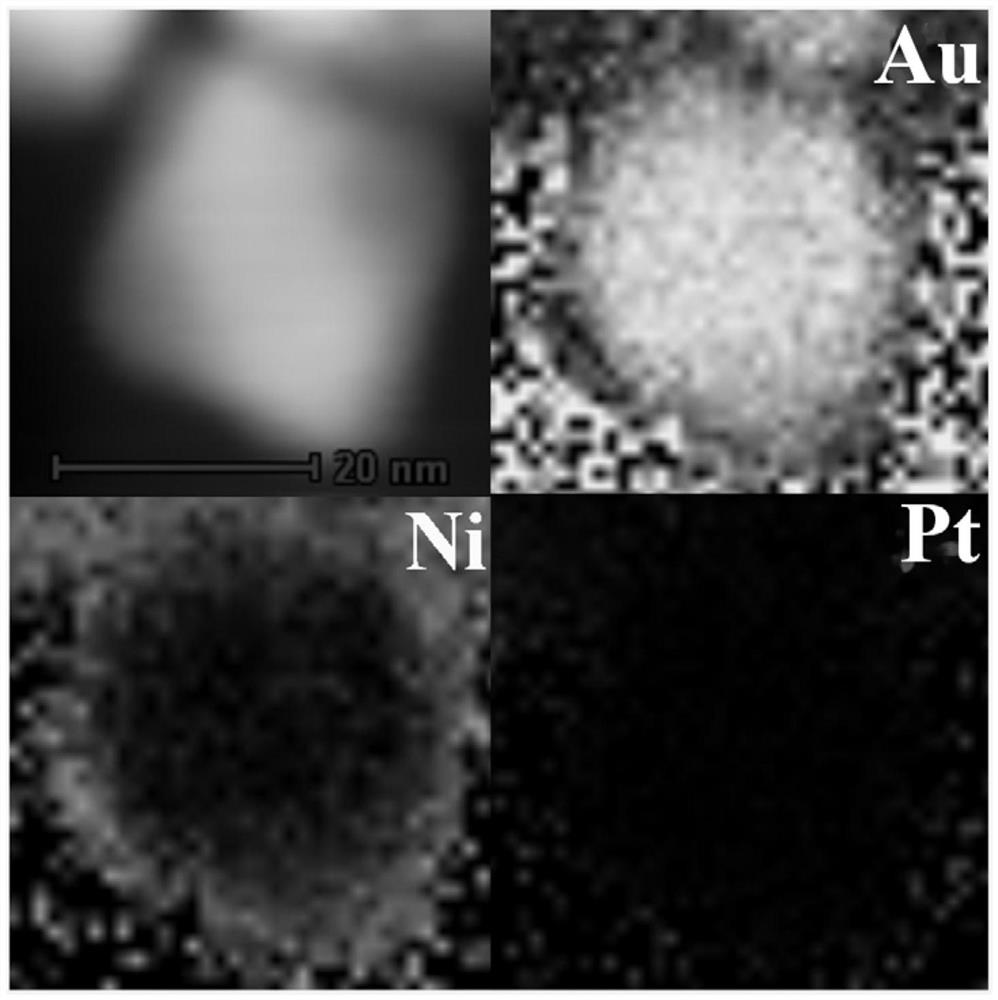

Image

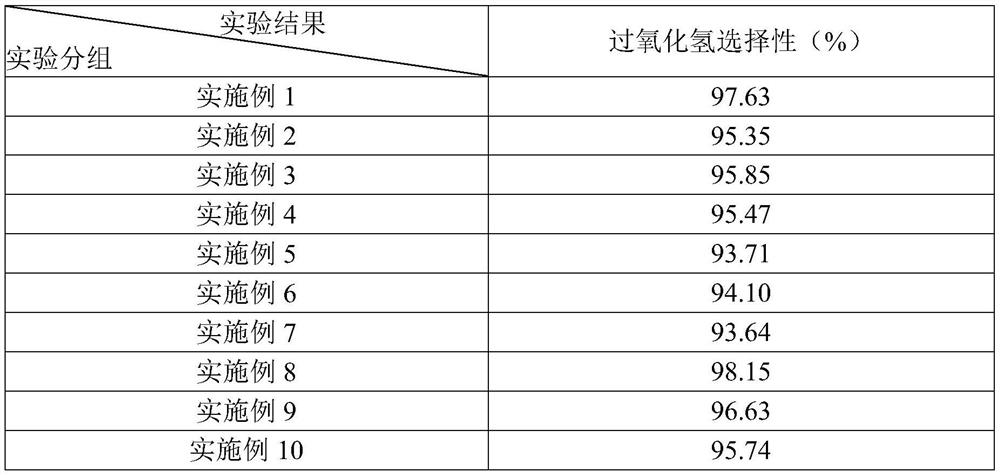

Examples

Embodiment 1

[0036]This embodiment provides an electrocatalytic material for producing hydrogen peroxide, which is prepared through the following steps:

[0037] Add 0.6mL of freshly prepared sodium borohydride (0.01M) ice-water solution to a mixed solution of 0.1M chloroauric acid (0.025mL) and cetyltrimethylammonium bromide (10mL) to prepare into a seed solution. The above mixed solution was vigorously stirred for 2 minutes before use, and aged at room temperature for about 5 minutes before use.

[0038] Dissolve 7.288g of cetyltrimethylammonium bromide in 100mL of warm water at 55°C to make a solution with a concentration of 0.2M, add 2mL of silver nitrate solution with a concentration of 0.01M to the solution, and let it stand at room temperature for 10 Minutes later, add 100mL of chloroauric acid solution with a concentration of 0.8mM, stir the mixed solution gently for about 10 minutes, add 0.9mL of freshly prepared ascorbic acid solution (0.1M), stir rapidly until the solution beco...

Embodiment 2

[0044] This embodiment provides an electrocatalytic material for producing hydrogen peroxide, which is prepared through the following steps:

[0045] Add 0.6mL of freshly prepared sodium borohydride (0.01M) ice-water solution to a mixed solution of 0.1M chloroauric acid (0.025mL) and cetyltrimethylammonium bromide (10mL), Make a seed solution. The above mixed solution was vigorously stirred for 2 minutes before use, and aged at room temperature for about 5 minutes before use.

[0046] Dissolve 7.288g of cetyltrimethylammonium bromide in 100mL of warm water at 55°C to make a solution with a concentration of 0.2M, add 2mL of silver nitrate solution with a concentration of 0.01M to the solution, and let it stand at room temperature for 10 Minutes later, add 100mL of chloroauric acid solution with a concentration of 0.8mM, stir the mixed solution gently for about 10 minutes, add 0.9mL of freshly prepared ascorbic acid solution (0.1M), stir rapidly until the solution becomes color...

Embodiment 3

[0051] This embodiment provides an electrocatalytic material for producing hydrogen peroxide, which is prepared through the following steps:

[0052] Add 0.6mL of freshly prepared sodium borohydride (0.01M) ice-water solution to a mixed solution of 0.1M chloroauric acid (0.025mL) and cetyltrimethylammonium bromide (10mL) to prepare into a seed solution. The above mixed solution was vigorously stirred for 2 minutes before use, and aged at room temperature for about 5 minutes before use.

[0053] Dissolve 7.288g of cetyltrimethylammonium bromide in 100mL of warm water at 55°C to make a solution with a concentration of 0.2M, add 2mL of silver nitrate solution with a concentration of 0.01M to the solution, and let it stand at room temperature for 10 minutes Finally, add 100mL of chloroauric acid solution with a concentration of 0.8mM, stir the mixed solution gently for about 10 minutes, add 0.9mL of freshly prepared ascorbic acid solution (0.1M), and stir rapidly until the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com