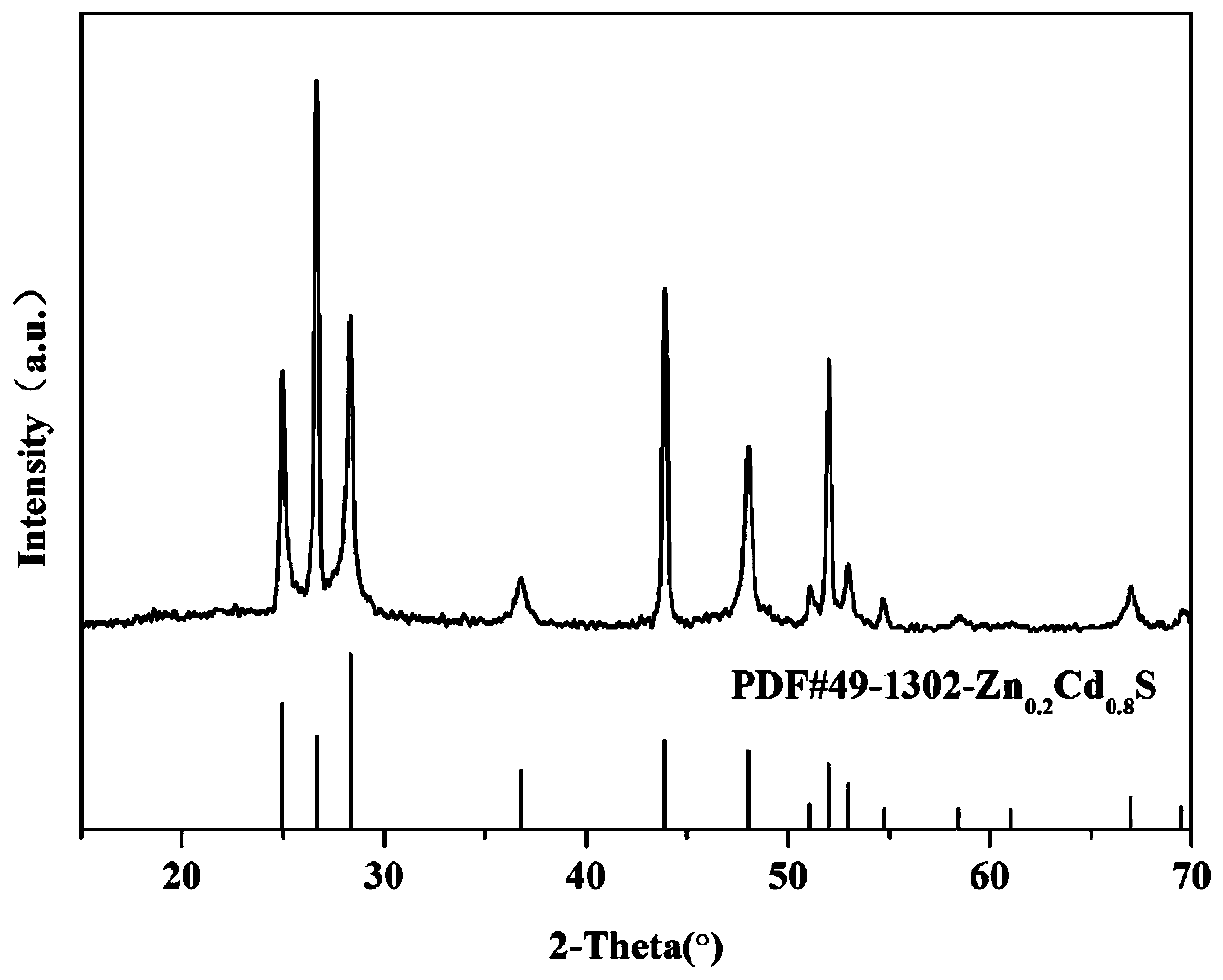

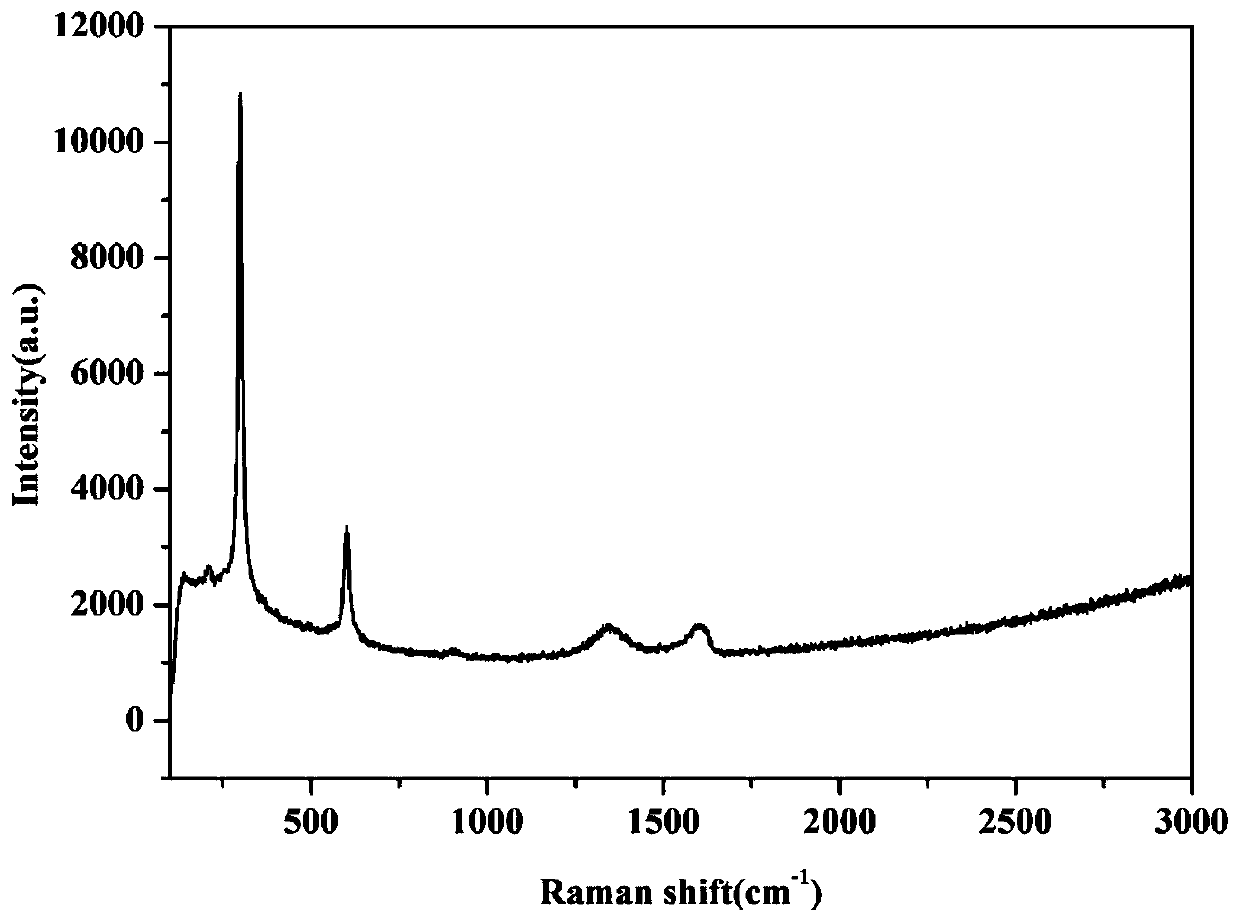

Preparation method of Zn0.2Cd0.8S / rGO photocatalytic material

A technology of photocatalytic materials and mixed solutions, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as harsh reaction conditions and toxicity, and achieve excellent hydrogen production performance and simple preparation process Easy-to-control, high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Step 1: Take 39.6mL deionized water and add 0.4mL hydrofluoric acid to it and magnetically stir for 5min to form a mixed solution A;

[0036] Step 2: Take 0.25mmol of Zn(Ac) according to the molar ratio of Zn:Cd of 1:4 2 2H 2 O and 1mmol of Cd(NO 3 ) 2 4H 2 O was added to mixed solution A, and magnetically stirred for 10 minutes to form mixed solution B;

[0037] Step 3: Take 2 mmol of thiourea as a sulfur source and add it to the mixed solution B, and magnetically stir for 10 minutes to form a mixed solution C;

[0038] Step 4: Add the mixed solution C into the polytetrafluoroethylene lining at a filling ratio of 40% and react with hydrothermal reaction at 140°C for 12 hours;

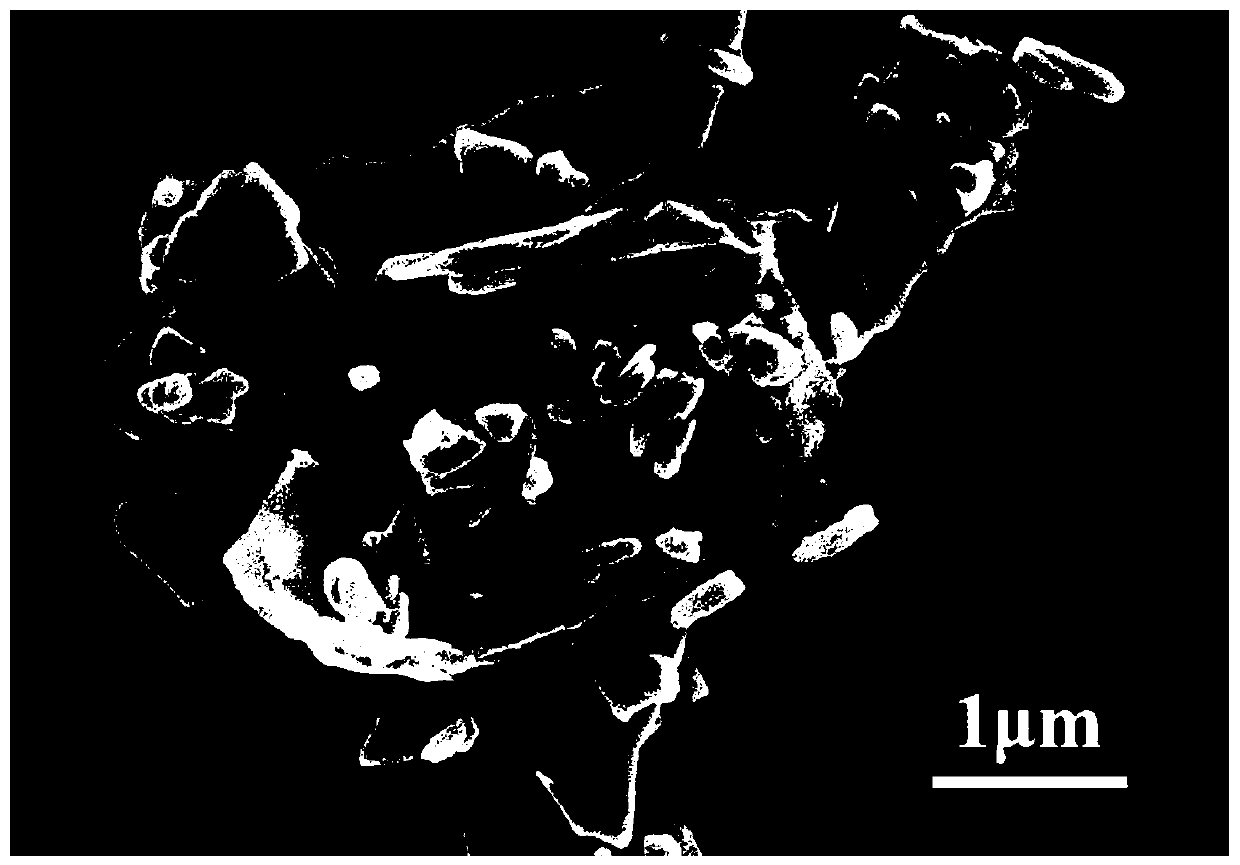

[0039] Step 5: After the reaction is completed, the reaction product is centrifuged and washed three times with deionized water and ethanol respectively, dried in vacuum at 60°C for 6 hours, and ground to obtain leaf-like Zn 0.2 Cd 0.8 S powder;

[0040] Step 6: Take 39mL of deionized wat...

Embodiment 2

[0045] Step 1: Take 49.4mL deionized water and add 0.6mL hydrofluoric acid to it and stir magnetically for 10min to form a mixed solution A;

[0046] Step 2: Take 0.5mmol of Zn(Ac) according to the molar ratio of Zn:Cd of 1:4 2 2H 2 O and 2mmol of Cd(NO 3 ) 2 4H 2 O was added to mixed solution A, and magnetically stirred for 20 minutes to form mixed solution B;

[0047] Step 3: Take 4 mmol of thiourea as a sulfur source and add it to the mixed solution B, and magnetically stir for 20 minutes to form a mixed solution C;

[0048] Step 4: Add the mixed solution C into the polytetrafluoroethylene lining at a filling ratio of 50% and react with hydrothermal reaction at 160°C for 24 hours;

[0049] Step 5: After the reaction is completed, the reaction product is centrifugally washed with deionized water and ethanol for 4 times, dried in vacuum at 70°C for 8 hours, and ground to obtain leaf-like Zn 0.2 Cd 0.8 S powder;

[0050] Step 6: Take 48mL of deionized water and add 2mL...

Embodiment 3

[0055] Step 1: Take 59.2mL deionized water and add 0.8mL hydrofluoric acid to it and stir it magnetically for 15min to form a mixed solution A;

[0056] Step 2: Take 0.75mmol of Zn(Ac) according to the molar ratio of Zn:Cd of 1:4 2 2H 2 O and 3mmol of Cd(NO 3 ) 2 4H 2 O was added to mixed solution A, and magnetically stirred for 30 minutes to form mixed solution B;

[0057] Step 3: Take 6 mmol of thiourea as a sulfur source and add it to the mixed solution B, and magnetically stir for 30 minutes to form a mixed solution C;

[0058] Step 4: Add the mixed solution C into the polytetrafluoroethylene lining at a filling ratio of 60% and react with hydrothermal reaction at 180°C for 18 hours;

[0059] Step 5: After the reaction is completed, the reaction product is centrifugally washed with deionized water and ethanol for 5 times, dried in vacuum at 80°C for 10 hours, and ground to obtain leaf-like Zn 0.2 Cd 0.8 S powder;

[0060] Step 6: Take 57mL of deionized water and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com