Methods for preparing nanometer cerium dioxide having specific crystal faces

A nano-ceria, nano-ceria technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of large size of nano-ceria, low specific surface area, and inability to give full play to the advantages of ceria , to achieve the effect of cost saving, large specific surface area and more catalytic active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

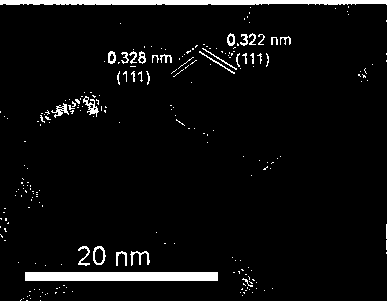

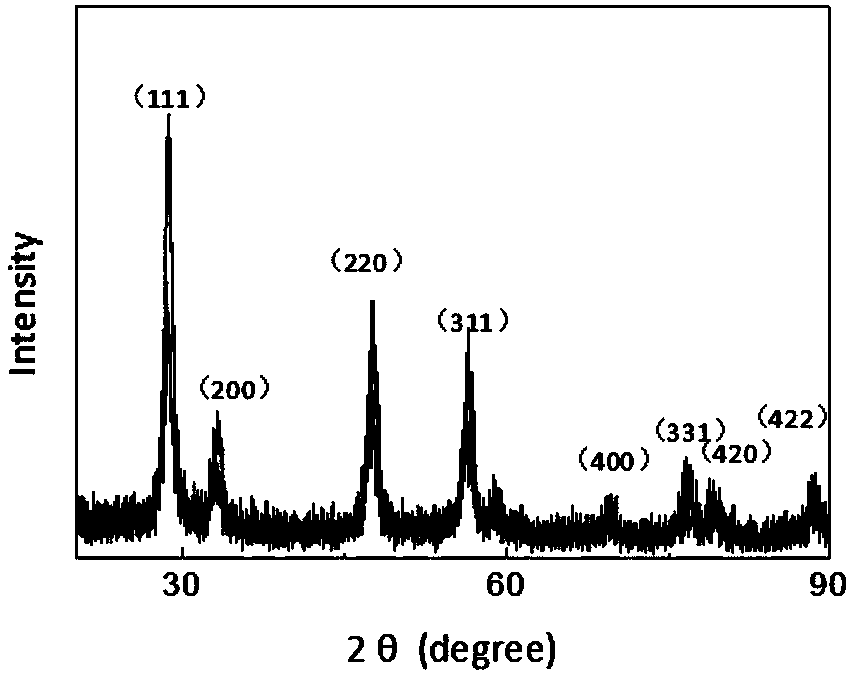

[0034] Preparation of nano-ceria with {111} crystal plane orientation.

[0035] (1) 1.302g of cerium nitrate hexahydrate was dissolved in 10mL of deionized water, in addition, 0.36g of NaOH was dissolved in 20mL of deionized water, and magnetically stirred to form two uniform solutions;

[0036] (2) Under the condition of magnetic stirring, the NaOH solution was added dropwise to the cerium nitrate hexahydrate solution, gradually a precipitate was formed, and finally a purple suspension was formed, and the stirring was continued for 30 minutes;

[0037] (3) Transfer the suspension in 2) to a 50mL polytetrafluoroethylene liner, put it into a reaction kettle, put the reaction kettle into a blast drying oven controlled by resistance, keep it warm at 180°C for 24h, and then put The reactor was naturally cooled to room temperature.

[0038] (4) The product obtained in 3) was centrifuged three times with deionized water and ethanol, and then dried in the air at 60°C for 24 hours to...

Embodiment 2

[0040] Preparation of nano-ceria with {110} and {100} crystal plane orientations.

[0041] (1) 1.302g of cerium nitrate hexahydrate was dissolved in 10mL of deionized water, 3.6g of NaOH was dissolved in 20mL of deionized water, and magnetically stirred to form two uniform solutions;

[0042] (2) Under the condition of magnetic stirring, the NaOH solution was added dropwise to the cerium nitrate hexahydrate solution, gradually a precipitate was formed, and finally a purple suspension was formed, and the stirring was continued for 30 minutes;

[0043](3) Transfer the suspension in 2) to a 50mL polytetrafluoroethylene liner, put it into a reaction kettle, put the reaction kettle into a blast drying oven controlled by resistance, keep it warm at 100°C for 24h, and then put The reactor was naturally cooled to room temperature.

[0044] (4) The product obtained in 3) was centrifuged three times with deionized water and ethanol, and then dried in the air at 60°C for 24 hours to obt...

Embodiment 3

[0046] Preparation of nano-ceria with {100} crystal plane orientation.

[0047] (1) 1.302g of cerium nitrate hexahydrate was dissolved in 10mL of deionized water, 0.72g of NaOH was dissolved in 20mL of deionized water, and magnetically stirred to form two uniform solutions;

[0048] (2) Under the condition of magnetic stirring, the NaOH solution is added dropwise to the cerium nitrate hexahydrate solution, gradually producing a precipitate, finally forming a purple suspension, and continuing to stir for 30 minutes;

[0049] (3) Transfer the suspension in 2) to a 50mL polytetrafluoroethylene liner, put it into a reaction kettle, then put the reaction kettle into a resistance-controlled blast drying oven, keep it warm at 180°C for 24h, and then The reaction kettle was naturally cooled to room temperature.

[0050] (4) The product obtained in 3) was centrifuged three times with deionized water and ethanol, and then dried at 60° C. in the air for 24 hours to obtain a white solid,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com