Preparation method of C/CoS2 nanotube structure regulated and controlled by self-template

A nanotube, self-template technology, applied in the direction of carbon nanotubes, nanotechnology for materials and surface science, nanocarbon, etc., can solve the problems of low electrocatalytic performance, few chemical active sites, small specific surface area, etc. The effect of large specific surface area, high product purity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

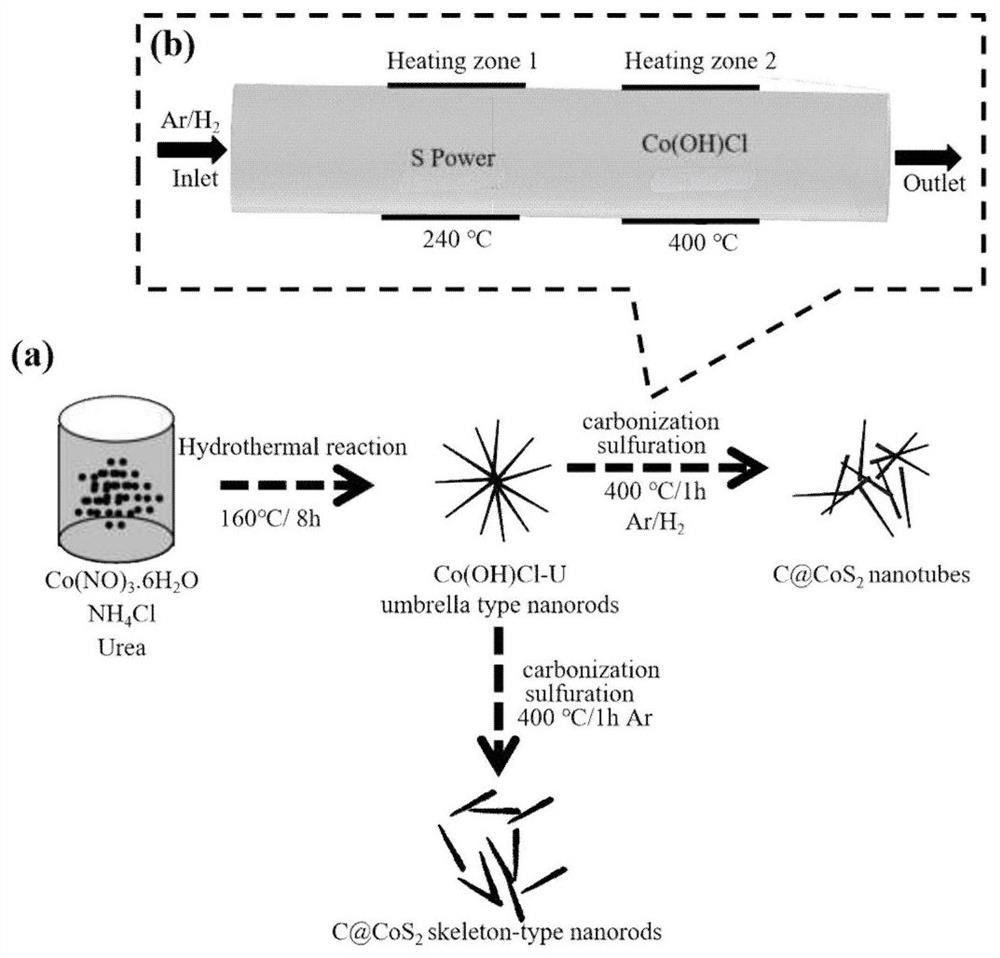

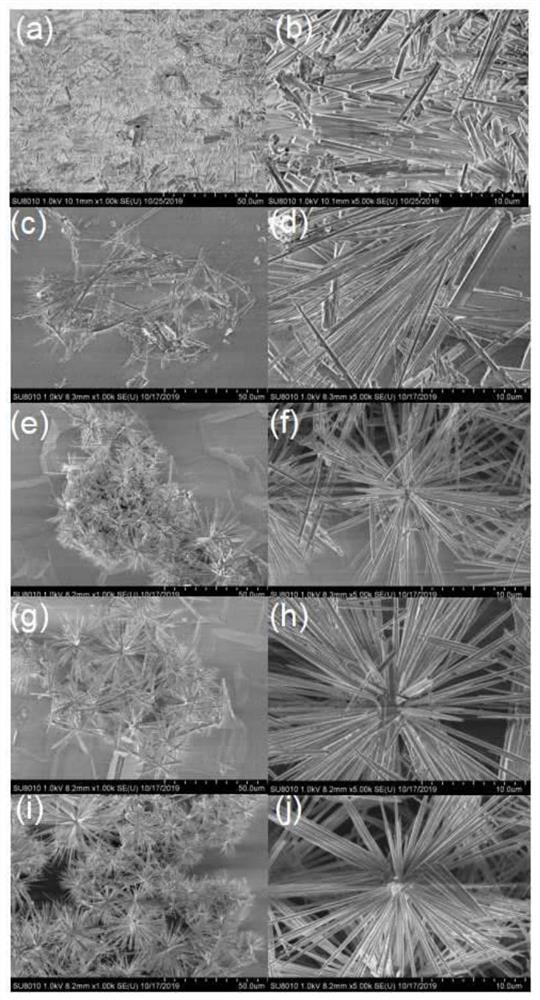

[0048] This example prepares C / CoS according to the following steps 2 Chained nanorods:

[0049] a. Weigh 0.58g Co(NO 3 ) 2 ·6H 2 O or 0.47g CoCl 2 ·6H 2 O, 0.27g NH 4 Cl, 0.6g urea, mix it evenly and put it in a 50ml beaker, add 35ml deionized water, stir it evenly, then put it in a 50ml reaction kettle, put it in an oven for 6-12 hours, and the reaction temperature is 140°C , to obtain the initial product Co(OH)Cl-urea;

[0050] b. After the reaction is cooled, take out the initial product Co(OH)Cl-urea, and then perform ultrasonication on the initial product Co(OH)Cl-urea to ensure its purity. The ultrasonication time is 20 minutes, and then use alcohol and deionized water several times Wash the initial product Co(OH)Cl-urea, and finally place the initial product Co(OH)Cl-urea in a vacuum drying oven for 12-24 hours, and the oven temperature is 60°C;

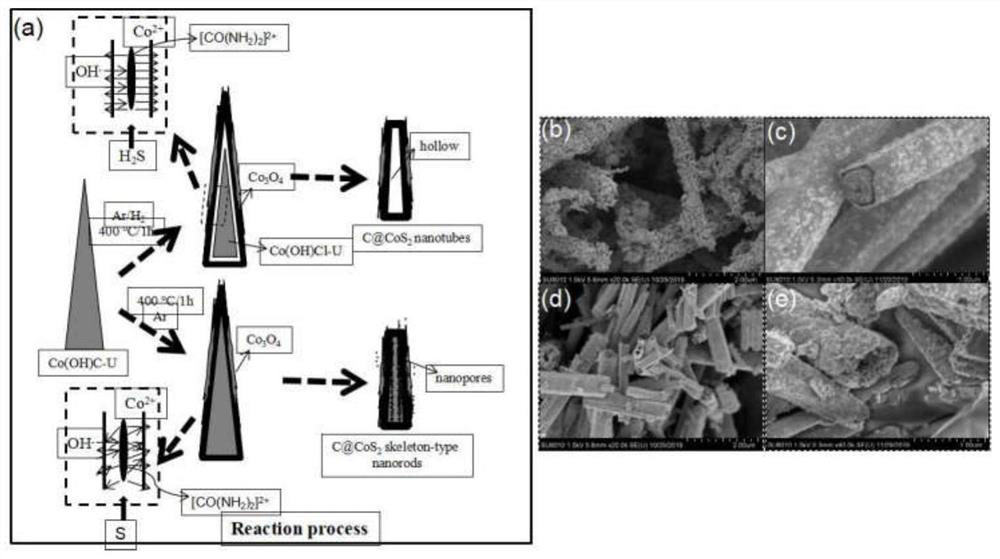

[0051] c. Weigh 0.01g of the initial product Co(OH)Cl-urea and place it in the high temperature zone of the chemica...

Embodiment 2

[0053] This example prepares C / CoS according to the following steps 2 Miscible Phases of Nanorods and Nanotubes:

[0054] a. Weigh 0.58g Co(NO 3 ) 2 ·6H 2 O or 0.47g CoCl 2 ·6H 2 O, 0.27g NH 4 Cl, 0.6g urea, mix it evenly and put it in a 50ml beaker, add 35ml deionized water, stir it evenly, then put it in a 50ml reaction kettle, put it in an oven for 6-12 hours, and the reaction temperature is 140°C , to obtain the initial product Co(OH)Cl-urea;

[0055] b. After the reaction is cooled, take out the initial product Co(OH)Cl-urea, and then perform ultrasonication on the initial product Co(OH)Cl-urea to ensure its purity. The ultrasonication time is 20 minutes, and then use alcohol and deionized water several times Wash the initial product Co(OH)Cl-urea, and finally place the initial product Co(OH)Cl-urea in a vacuum drying oven for 12-24 hours, and the oven temperature is 60°C;

[0056] c. Weigh 0.01g of the initial product Co(OH)Cl-urea and place it in the high temper...

Embodiment 3

[0058] This example prepares C / CoS according to the following steps 2 nanotube

[0059] a. Weigh 0.58g Co(NO 3 ) 2 ·6H 2 O or 0.47g CoCl 2 ·6H 2 O, 0.27g NH 4 Cl, 0.6g urea, mix it evenly and put it in a 50ml beaker, add 35ml deionized water, stir it evenly, then put it in a 50ml reaction kettle, put it in an oven for 6-12 hours, and the reaction temperature is 140°C , to obtain the initial product Co(OH)Cl-urea;

[0060] b. After the reaction is cooled, take out the initial product Co(OH)Cl-urea, and then perform ultrasonication on the initial product Co(OH)Cl-urea to ensure its purity. The ultrasonication time is 20 minutes, and then use alcohol and deionized water several times Wash the initial product Co(OH)Cl-urea, and finally place the initial product Co(OH)Cl-urea in a vacuum drying oven for 12-24 hours, and the oven temperature is 60°C;

[0061] c. Weigh 0.01g of the initial product Co(OH)Cl-urea and place it in the high temperature zone of the chemical vapor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com