Method for detecting defects in glassware articles, and installation for implementing said method

一种玻璃器皿、检测方法的技术,应用在用于检测玻璃器皿物品缺陷,以及用于实施所述的装置领域,能够解决不能检测图案暗区等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

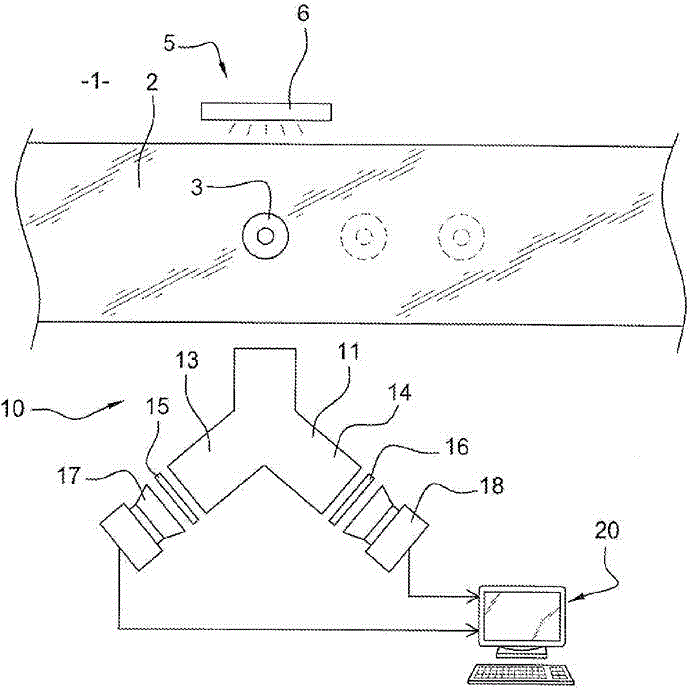

[0035] As previously stated, the present invention relates to a method and a device for detecting so-called transparency defects 1 in articles of glassware. An example of such a device is figure 1 As shown, the illustrated conveyor belt 2 , on which different product items 3 to be analyzed are placed, passes in front of the defect detection station 5 . In the illustration, the device comprises an analysis table 5 mainly formed by a light source 6 arranged on one side of the conveyor belt 2 and an image capture assembly 10 arranged on the other side. Of course, the invention also encompasses variations in which the analysis station includes multiple light source / image capture assemblies capable of analyzing the same article of manufacture according to multiple angles of incidence. Variations of the invention also include wherein the line of sight of the camera forms a non-zero angle with the direction perpendicular to the light source. The range of different angles within whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com