Processing method for phi 52H7*850 deep hinge pin keyhole at matched position of parts of different materials

A technology of deep pin key hole and processing method, which is applied in the field of mechanical processing technology, can solve problems such as difficulty in processing high-precision ultra-deep holes, and achieve the effects of solving assembly accuracy problems, high machining accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

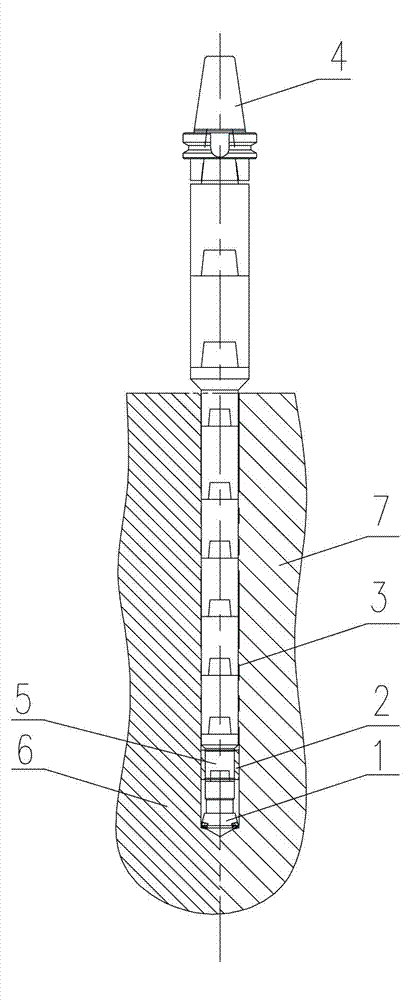

[0035] see figure 1 , the method of the present invention is used to process the Φ52H7×850 deep pin keyhole at the joint between the large flywheel 7 (ZG270-500) and the main shaft 6, and the specific process steps are as follows:

[0036] (1) Drill the center hole at the processing position of φ52H7, cutting amount: speed n=300r / min, axial feed F=10mm / min;

[0037] (2) Drilling process hole φ42×150mm, cutting amount: speed n=120r / min, axial feed F=9mm / min;

[0038] (3) Bore the φ42mm hole to the size φ45H8 and the depth is 100mm, roughness Ra=3.2, cutting amount: speed n=130r / min, axial feed F=9mm / min, the cutting depth of the last two knives t= 0.1mm;

[0039] (4) Use the φ45H7×100mm hole as the φ45mm drill guide hole; add coolant, first use the φ45mm drill to feed along the φ45H7 hole, correct the φ42mm offset of the process hole, and drill slowly until the hole tip, the depth must exceed 160mm : When the drill tip is in contact with the original hole tip and cutting, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com