Stereo scanning laser lamp without slip ring

A three-dimensional scanning and laser light technology, applied in the field of laser light, can solve the problems of corrosion, contact wear resistance, corrosion resistance, relatively high electrical conductivity, life impact, etc., to improve stability and reliability, transmission mode Precise and reliable, reliable connection and transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

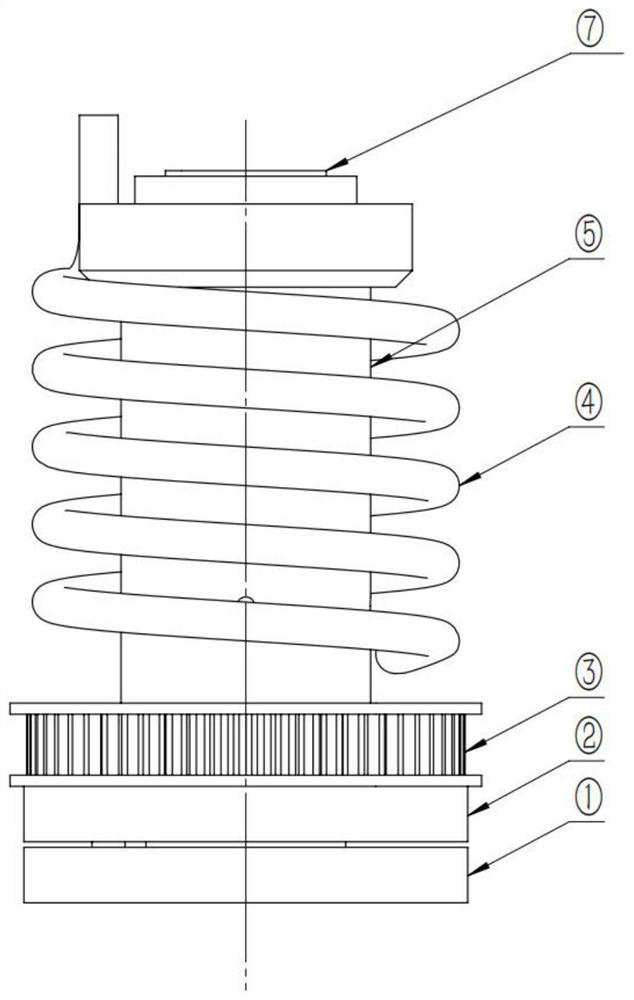

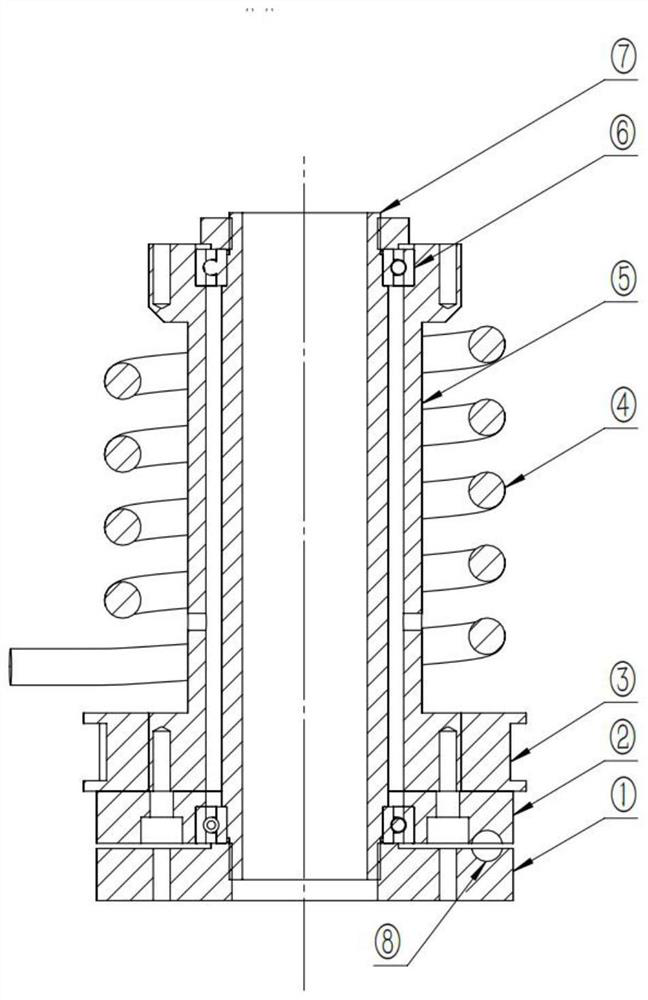

[0027] see Figure 1-2 , a three-dimensional scanning laser light without slip ring, including:

[0028] a light guide tube assembly, the light guide tube assembly is used to provide the optical path and channel of the laser beam;

[0029] Spiral signal transmission assembly, the spiral signal transmission assembly is sleeved on the light guide tube assembly;

[0030] a movement component, which is sleeved on one end of the light guide tube component;

[0031] The spiral signal transmission component is a structure in which the wire is wound into a spiral shape. Its purpose is to provide different requirements for the change of the length of the wire during the movement of the moving component. There are three functions. The third is to prevent the cables from being entangled in the retraction and release of cables of different lengths.

[0032] The positioning component is used to ensure the movement and positioning of the moving component, and the positioning component is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com