System, method and device for prefabricating informatization whole-lifecycle pipeline

A full life cycle, pipeline technology, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve problems such as difficult data statistics, high management costs, and difficult queries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

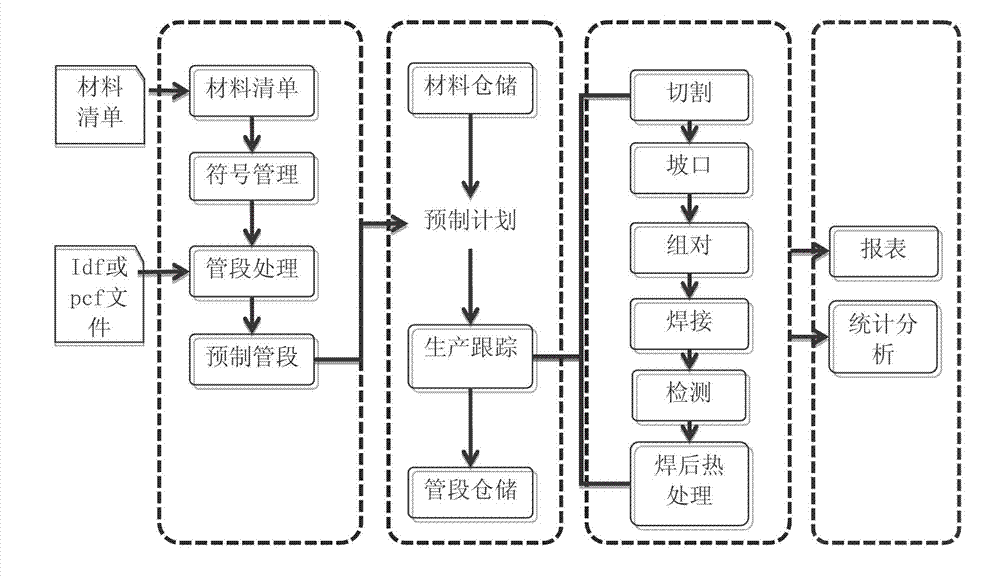

[0062] This embodiment is a pipeline informatization full life cycle system, including:

[0063] The prefabricated pipe section package generation module is used to form the prefabricated pipe section package for the ISO-IDF interface file output by the design software;

[0064] The prefabricated pipe section diagram generation module is used to set the prefabricated pipe section of the pipeline, and respectively generate the prefabricated pipe section diagram that meets the engineering specifications;

[0065] The pipeline material library definition module is used for the management and real-time inventory ledger of pipeline material storage and delivery, as well as material withdrawal;

[0066] Material inventory query module, used for material inventory query according to the prefabricated pipeline diagram;

[0067] Material statistics module, used for material statistics according to engineering projects, pipelines and pipe sections;

[0068] The barcode data generation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com