Scribe for Thermoplastic Pipe Inspection

A technology of thermoplastics and scribes, which is applied in workshop equipment, workpiece clamping devices, manufacturing tools, etc., can solve the problems of uneven scribing, inaccurate spacing, incoherent scribing, etc., and improve the efficiency of scribing , reduce the quantity, and ensure the rapid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

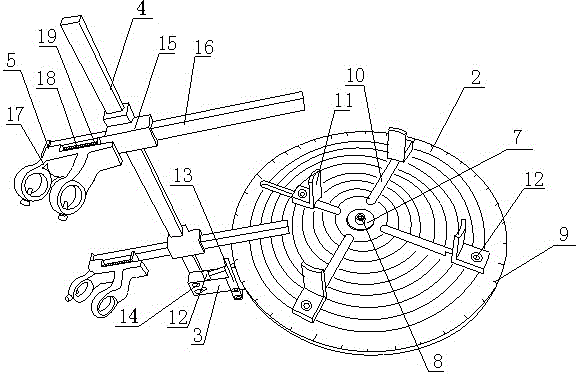

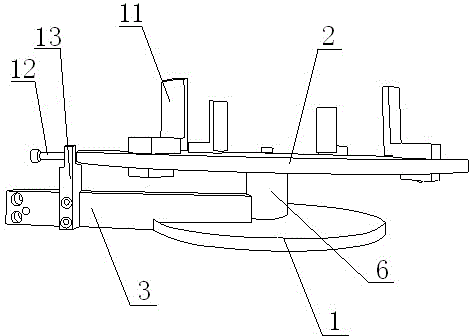

[0016] Such as figure 1 and 2 As shown, the thermoplastic pipe marking device of the present invention includes a circular base 1, a rotating disc 2, a connecting rod 3, a vertical rod 4 and two marking pen holders 5, and the top of the circular base 1 is connected to a Cylinder 6, the cylinder 6 is provided with a bearing 7, the rotating disc 2 is placed on the bearing 7, the center of the rotating disc 2 is provided with a through screw hole 8, and the edge of the rotating disc 2 is provided with an angle scale line 9, There are chute 10 on two mutually perpendicular diameter directions on the rotating disk 2, and the "L" type sliding clip 11 for positioning and clamping the pipe is arranged in the chute 10. The disc 2 is fixed, the circular base 1 is connected with the vertical rod 4 through the connecting rod 3, and the connecting rod 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com