Hydraulic overload protective system capable of setting tonnages and working method thereof

A technology of overload protection and overload protection valve, which is applied in the direction of presses, manufacturing tools, etc., can solve the problems that cannot meet the needs of setting different overload protection tonnages, it is difficult for users to obtain relevant information, and cannot be automatically set, etc., so as to achieve convenience Maintenance replacement and selection of spare parts, cost reduction, effect of green equipment industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

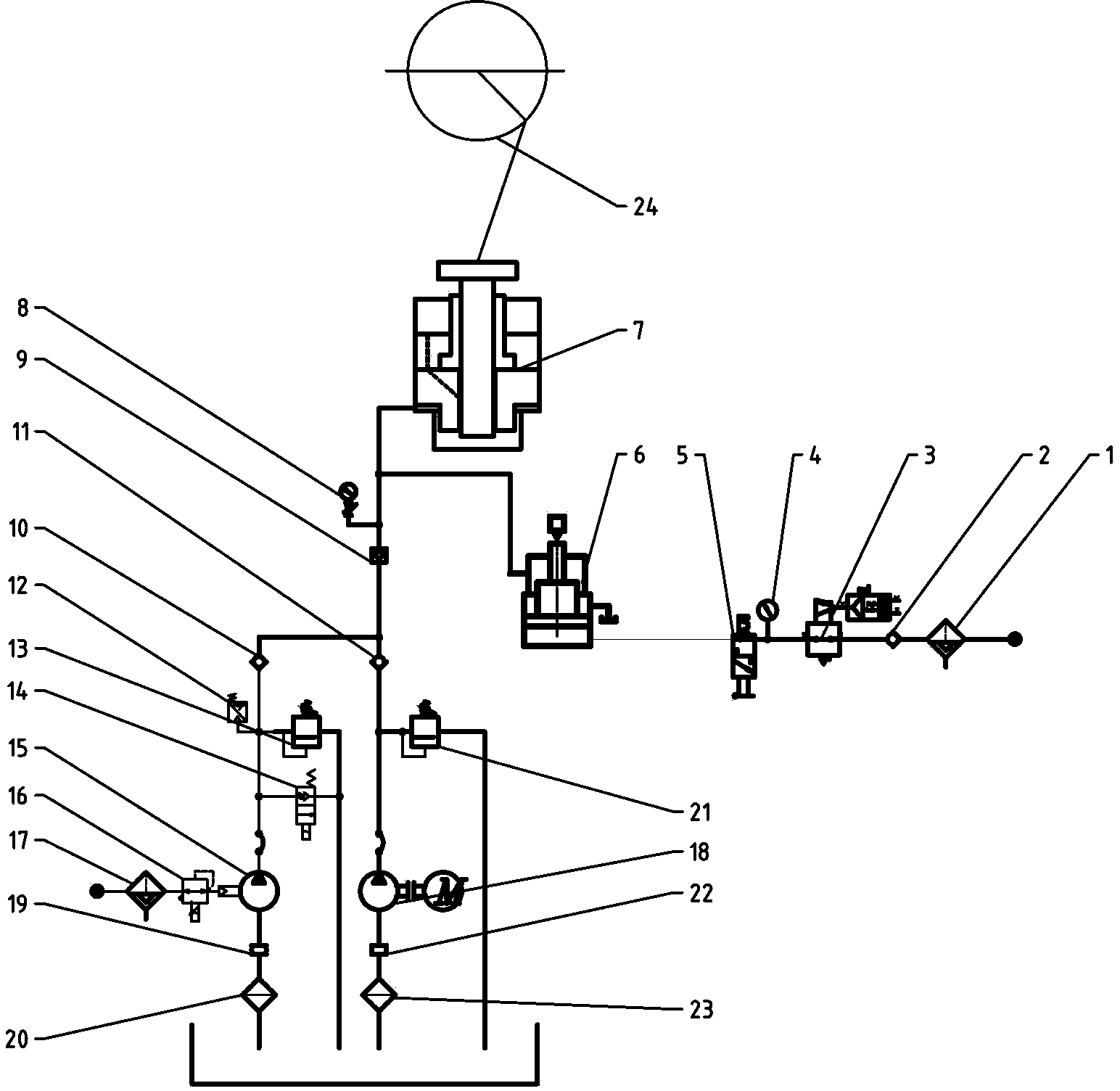

[0021] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a hydraulic overload protection system with set tonnage includes air filter A1, pneumatic proportional pressure regulating valve A3, manual ball valve 5, overload protection valve 6, hydraulic cushion 7, pressure sensor 12, safety valve A13, cut-off type Solenoid valve 14, pneumatic pump 15, pneumatic proportional pressure regulating valve B16, air filter B17, gear pump motor unit 18, shock absorber throat A19, oil suction filter A20, safety valve B21, shock absorber throat B22 and oil suction filter B23, It also includes a controller and a touch screen; one end of the air filter A1 is connected to the factory gas pipeline, and the other end is connected to the one-way valve A2, the pneumatic proportional pressure regulating valve A3, the manual ball valve 5, the overload protection valve 6 and the hydraulic pad 7 A pressure gauge A4 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com